Space navigation high-speed cable assembly assembling and connecting method

A cable assembly and aerospace technology, applied in the field of aerospace high-speed cable connection, can solve the problems of discontinuous shielding and large crosstalk, and achieve the effects of electromagnetic protection, improved reliability, and broad market application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to make the technical solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

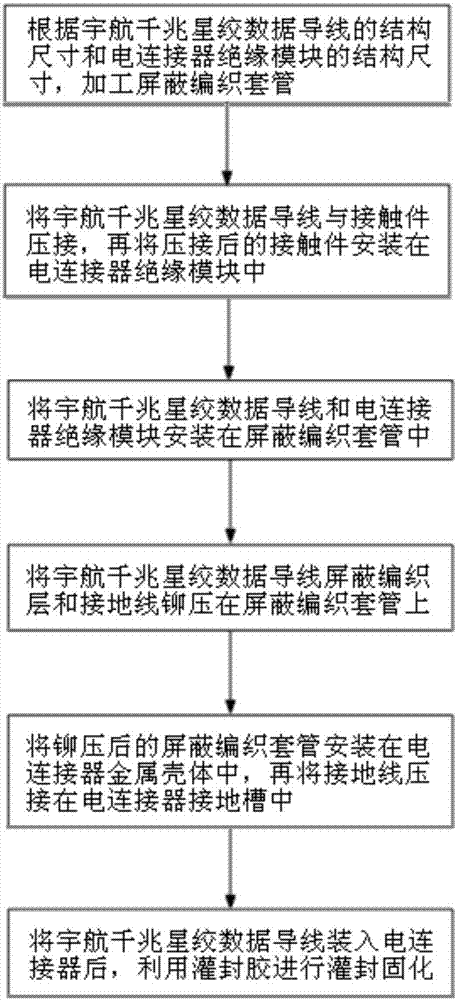

[0039] Such as Figure 1~4 As shown, a method for mounting an aerospace high-speed cable assembly includes the following steps:

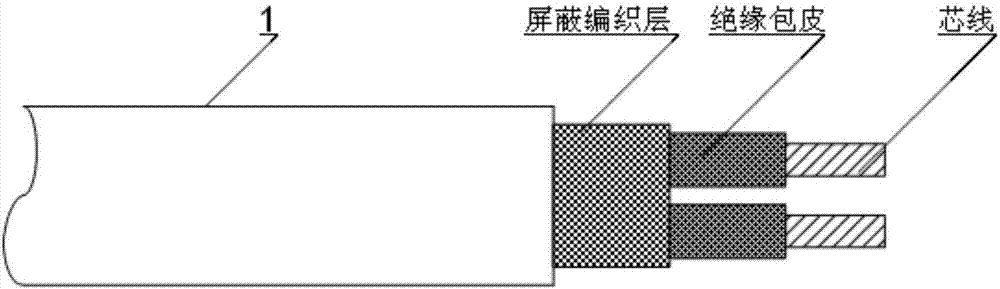

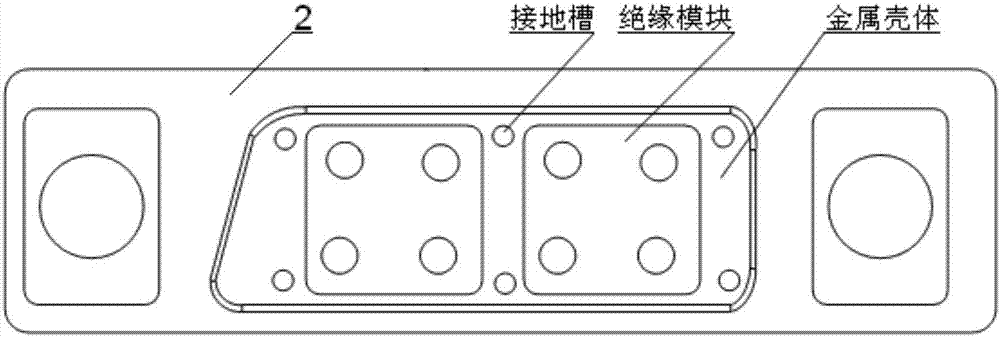

[0040] Step 1: Process the shielding braided sleeve 3 according to the structural size of the aerospace gigabit star-stranded data wire 1 and the structural size of the electrical connector 2 insulation module;

[0041] Step 2: Crimp the aerospace gigabit star-stranded data wire 1 with the contact piece 4, and then install the crimped contact piece 4 in the insulation module of the electrical connector 2;

[0042] Step 3: Install the aerospace gigabit star-stranded data wire 1 and the electrical connector 2 insulation module in the shielding braided sleeve 3;

[0043] Step 4: Rivet and press the shielding braiding layer and grounding wire 5 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com