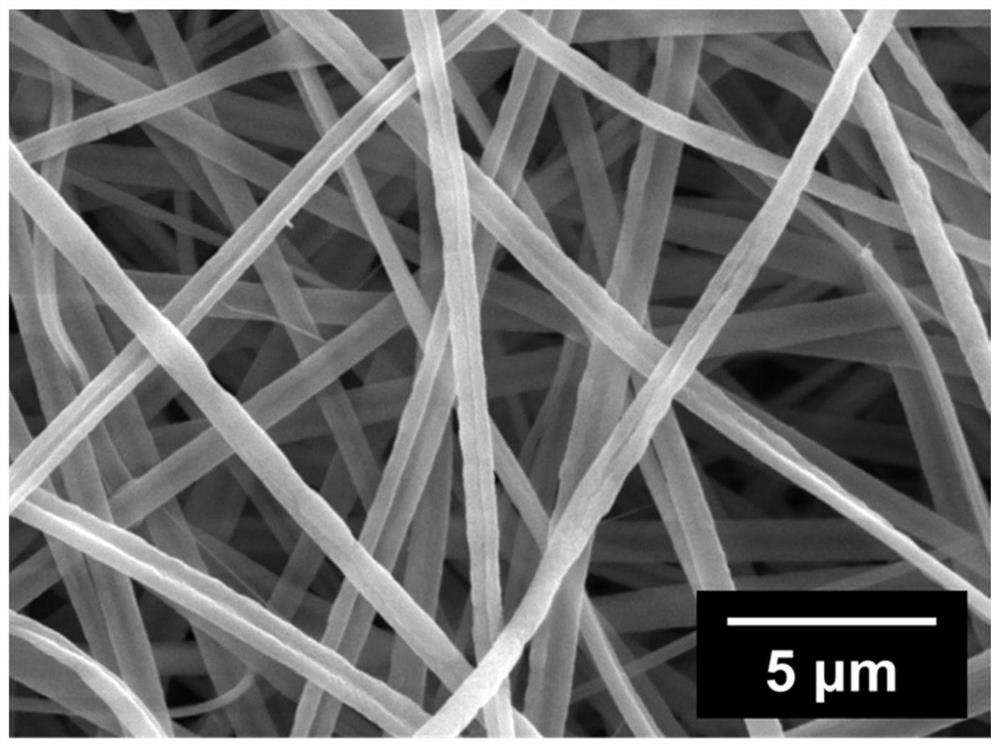

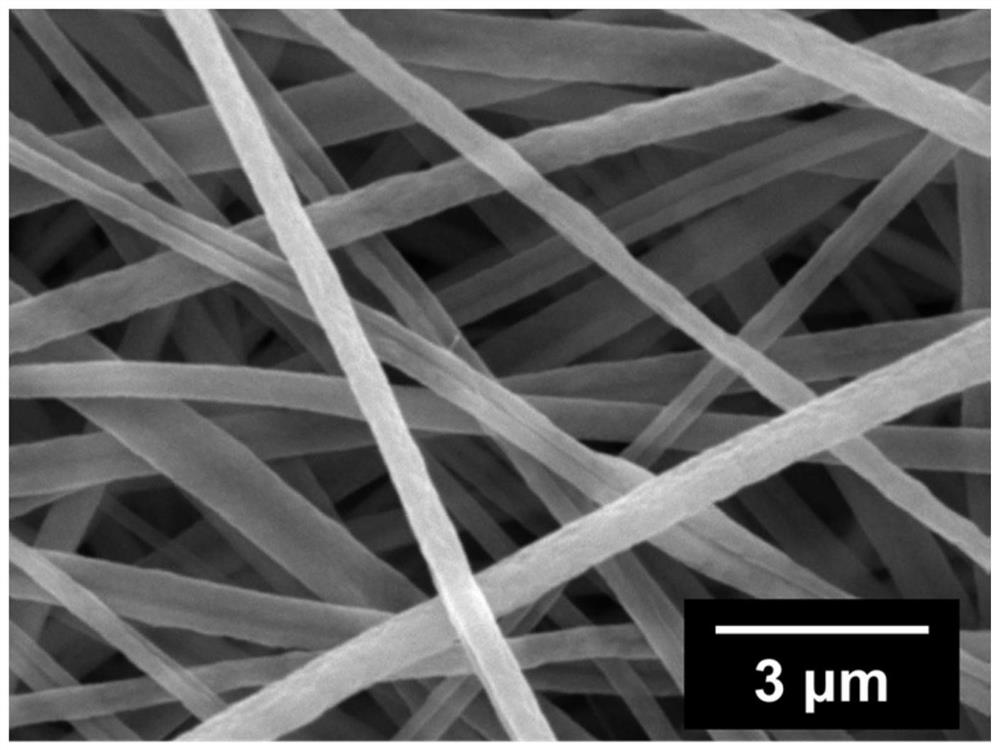

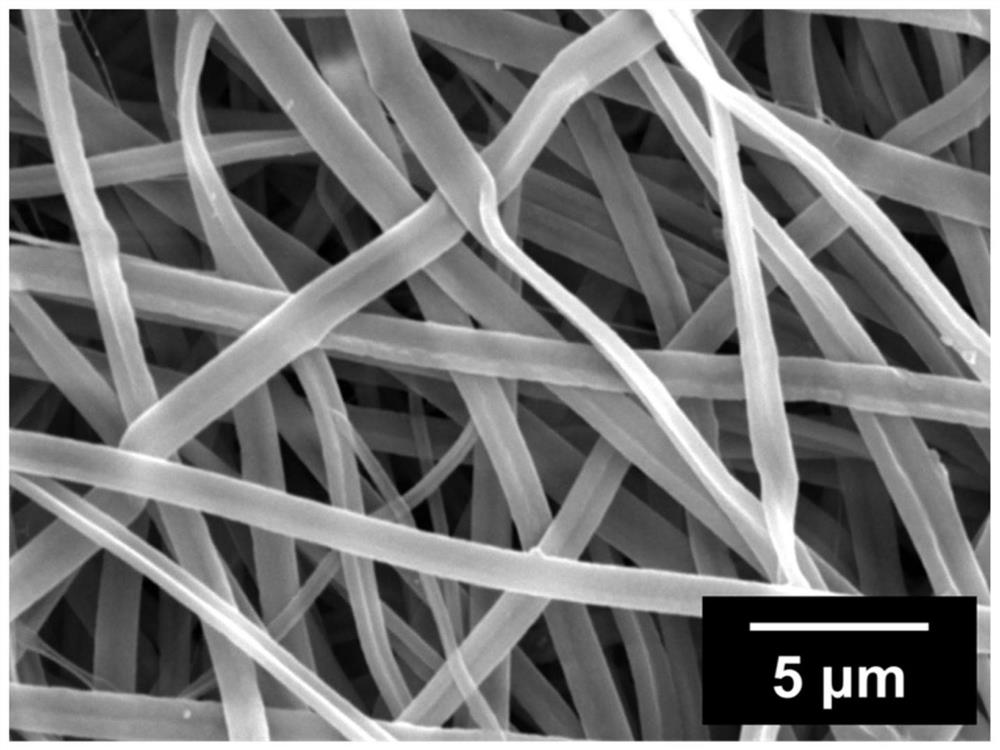

Flexible metal hydroxide nanofiber material as well as preparation method and application thereof

A technology of nanofibers and hydroxides, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of material inflexibility, etc., and achieve the effect of rich and adjustable pore structure, good flexibility and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The invention provides a method for preparing a flexible metal hydroxide nanofiber material, comprising the following steps:

[0033] 1) Dissolving the inorganic precursor in a solvent, then adding a coordination protective agent, and stirring thoroughly to obtain a ligand-protected linear inorganic sol with low branching degree;

[0034] 2) Control the hydrolysis and polycondensation of the inorganic precursor to prepare a linear inorganic spinning sol with a high degree of polymerization and a low degree of branching;

[0035] 3) Using a temperature / alkali steam-assisted spinning process, the linear inorganic spinning sol is prepared into gel nanofibers;

[0036] 4) The gel nanofibers are treated with an ultrasonic-assisted alkaline solution to complete an alcoholysis reaction with a high degree of hydroxyl substitution, and then cleaned and dried to obtain a flexible metal hydroxide nanofiber material.

[0037] In step 1), the inorganic precursor includes zirconium ...

Embodiment 1

[0044] Dissolve 12wt% zirconium n-propoxide into a mixed solvent of n-propanol and ethanol (the solvent mass ratio is 1:1), the stirring rate is 500rpm, and the stirring temperature is 26°C. After fully stirring, add acetylacetone 8wt, a coordination protection agent %, and then stirred at room temperature for 8 hours to obtain a homogeneous multidentate ligand-protected inorganic sol. The sol was passed through a low-branched inorganic polymer sol spinning solution batch preparation device to control the hydrolysis and polycondensation of the inorganic precursor, and the polycondensation negative The pressure was controlled at 0.1MPa, the reaction temperature was 60°C, and the polycondensation time was 3h. Finally, a linear inorganic spinning sol with a degree of polymerization of 6500 and a degree of branching of ~0.05 was obtained, with a viscosity of 1800mpa·s.

[0045] Put the high degree of polymerization and low degree of branching linear inorganic spinning sol prepared ...

Embodiment 2

[0049] Dissolve 13wt% aluminum n-propoxide into n-propanol with a stirring rate of 500rpm and a stirring temperature of 26°C. After fully stirring, add 11wt% of coordination protective agent acetylacetone, and then stir at room temperature for 8 hours to obtain a homogeneous multi-dentate complex. Body-protected inorganic sol, the sol is passed through a low-branched inorganic polymer sol spinning solution batch preparation device to control the hydrolysis and polycondensation of the inorganic precursor, the polycondensation negative pressure is controlled at 0.1MPa, the reaction temperature is 60 ° C, the polycondensation time After 3 hours, a linear inorganic spinning sol with a degree of polymerization of 8200 and a degree of branching of ~0.05 was finally obtained, with a viscosity of 2400 mpa·s.

[0050] Put the high degree of polymerization and low branching linear inorganic spinning sol prepared above into the slit nozzle, and apply 25kV high voltage to the tip, control ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com