Preparation method of high-grade colorless diamond

A high-grade diamond technology, applied in the field of preparation of high-grade colorless diamonds, can solve problems such as crystal yellowing, achieve the effects of poor quality and increase crystal growth speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] The catalyst composition (percentage) is: FeNiCo alloy (mass percentage Fe: 54%, Ni: 29%, Co: 17%) accounts for 97% of the catalyst, Ti is 1.5% and Cu is 1.5%. Select the best process of this catalyst as a comparison. The process is as follows: ①After the diamond composite block is put into the domestic six-sided press, start to pressurize. When the pressure reaches 7.0MPa (oil pressure, the same below), start to overpressure quickly, After 100s, the pressure rises to 40.0MPa, at this time, start heating (measured by power); ②After 120s, the pressure rises to 78.0MPa, at this time, the power rises to 2.2kw, and heat preservation begins; ③After the pressure is 80s, Raise to 88.0MPa, start holding pressure; during the holding period, the power rises to 3.7kw, and keep warm for 240s; ④After 240s of holding, the power rises from 3.7kw to 4.9kw, and then after 200s, the power rises to 5.7kw, and the power starts to remain unchanged , keep warm; ⑤ keep the pressure at 88.0MPa...

Embodiment 2

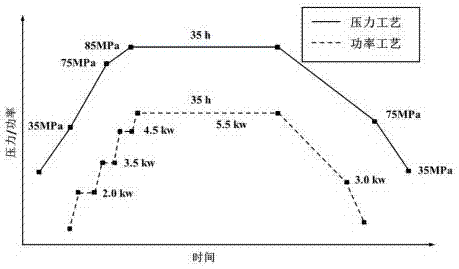

[0024] Raw material weight percentages of the catalytic alloy sheet: Fe: 78.0%, Ni: 17.0%, Ti: 2.0%, Cu: 2.0%, Al: 1.0%. Synthetic process such as figure 1 Shown: ① After the diamond composite block is put into the domestic six-sided top press, pressurization starts. When the pressure reaches 7.0MPa (oil pressure, the same below), it starts to overpressure rapidly. After 100s, the pressure rises to 35.0MPa. At this time, start to heat up (measured by power); ②The pressure rises to 75.0MPa after 120s, and the power rises to 2.0kw at this time, and the heat preservation starts; ③The pressure rises to 85.0MPa after 80s, and starts to hold the pressure; During the pressure period, the power increased to 3.5kw, and the temperature was kept for 240s; ④After 240s, the power was increased from 3.5kw to 4.5kw, and then after 200s, the power was increased to 5.5kw, and the power was kept unchanged, and the temperature was maintained; ⑤The pressure was maintained at 85.0MPa for 36h ; At...

Embodiment 3

[0026] Raw material weight percentages of the catalyst alloy sheet: Fe: 80.0%, Ni: 15.5%, Ti: 1.5%, Cu: 1.5%, Al: 1.5%. Synthetic process such as figure 1 Shown: ① After the diamond composite block is put into the domestic six-sided top press, pressurization starts. When the pressure reaches 7.0MPa (oil pressure, the same below), it starts to overpressure rapidly. After 100s, the pressure rises to 35.0MPa. At this time, start to heat up (measured by power); ②The pressure rises to 75.0MPa after 120s, and the power rises to 2.0kw at this time, and the heat preservation starts; ③The pressure rises to 85.0MPa after 80s, and starts to hold the pressure; During the pressure period, the power increased to 3.5kw, and the temperature was kept for 240s; ④After 240s, the power was increased from 3.5kw to 4.5kw, and then after 200s, the power was increased to 5.5kw, and the power was kept unchanged, and the temperature was maintained; ⑤The pressure was maintained at 85.0MPa for 36h ; At ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com