Multi-tooth online detection device and method for precision forging of straight-tooth conical gear

A straight-toothed bevel gear and detection device technology, applied in the direction of measuring devices, forging press drive devices, optical devices, etc., can solve problems such as high scrap rate, unqualified products, and inability to detect high-temperature gear parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

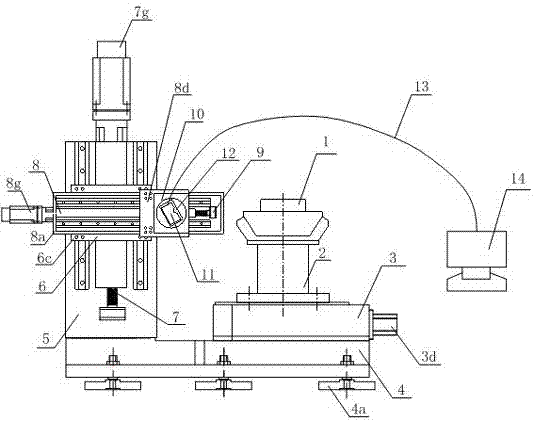

[0063] In conjunction with the accompanying drawings, the present invention can be explained in more detail through the following embodiments. The present invention is not limited to the following embodiments. The purpose of disclosing the present invention is to protect all changes and improvements within the scope of the present invention.

[0064] According to the characteristics of precision forging workpieces, the present invention adopts a non-contact online detection method to detect the following three items:

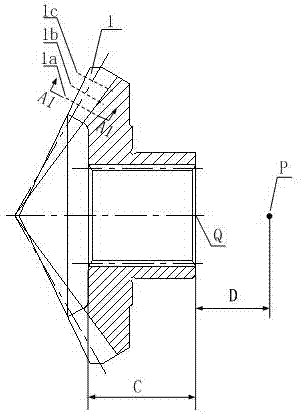

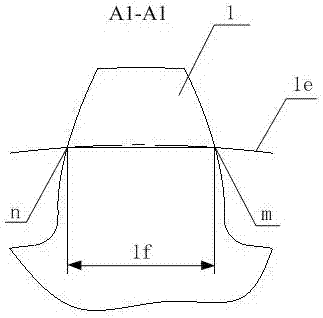

[0065] 1) String tooth thickness: by Figure 2~3 It is known that the present invention detects the chord tooth thickness of the straight bevel gear respectively on three normal sections at 1a, 1b and 1c from the small end in the tooth width direction, and compares it with the standard gear respectively. Detecting the thickness of the three chord teeth can effectively avoid the randomness caused by only detecting the chord tooth thickness at the middle point or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com