Spindle device special for valve element machining

A spindle device and valve core technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve problems such as deformation of valve core parts, and achieve the effect of improving the processing qualification rate and saving the installation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

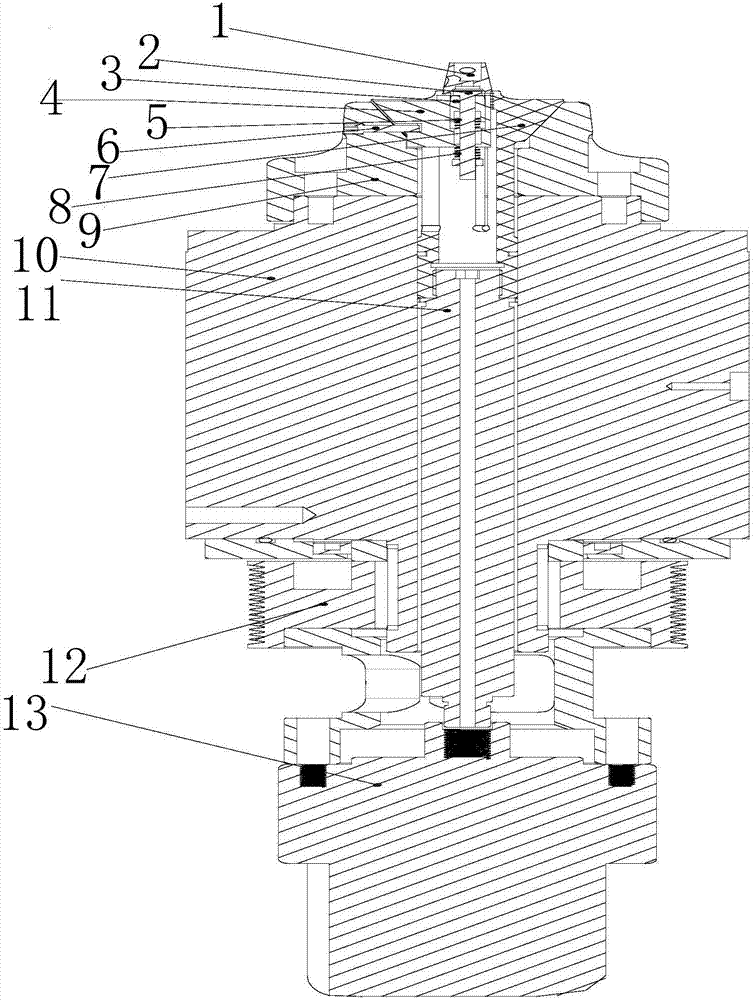

[0009] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0010] like figure 1 As shown, the special spindle device for spool processing of the present invention includes a thimble 2, a top sleeve 3, a bracket 4, an upper spring 5, a positioning screw 6, a ferrule 7, a lower spring 8, a fixed sleeve 9, a main shaft 10, a pull rod 11, and a pulley 12 , oil cylinder 13, at least one spool part 1 is located on the bracket 4 at the upper end of the main shaft 10, the thimble 2 is connected with the spool part 1 through the top sleeve 3, the upper spring 5 is located at the bottom of the top sleeve 3, and the positioning screw 6 is located on one side of the main shaft 10 side, the ferrule 7 is located on the other side of the main shaft 10, the lower spring 8 is located at the lower part of the bracket 4, the fixed sleeve 9 is located under the bra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com