Sleeving device and sleeving method for pipe system without guide rollers and shell

A technology of guide rollers and pipe systems, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve the problems of poor adaptability, small rigidity of pipe systems, and easy deformation, etc., to achieve easy assembly process, ensure precise fit, and stability The effect of the suit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

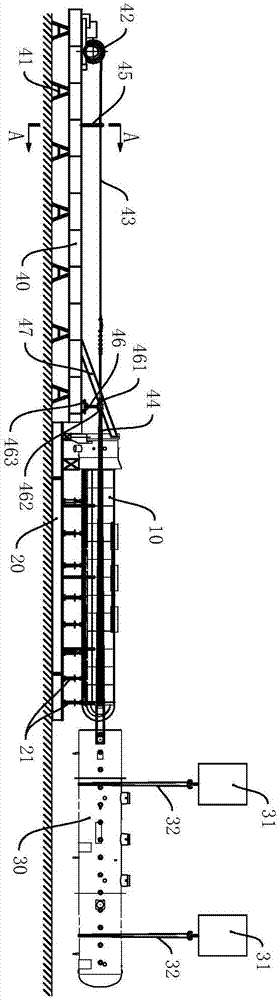

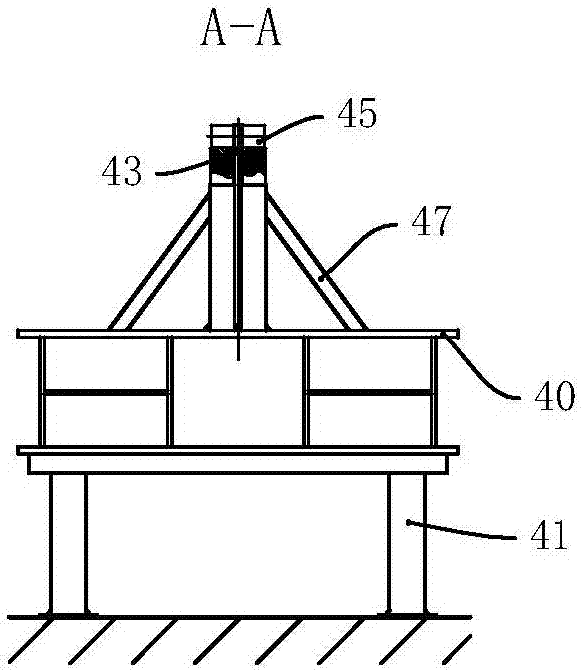

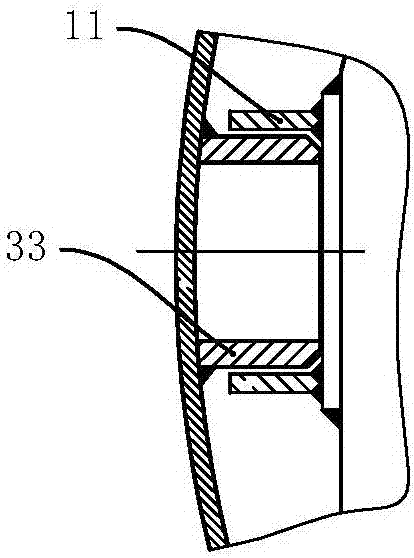

[0022] refer to Figure 1-3 , the present invention is a set device for a piping system without guide rollers and a casing, including a piping system 10, a casing 30, and a support platform 20 located below the piping system 10, and the support platform 20 is provided with several supports on the piping system. 10 bottom and mutually independent support unit 21, a working platform 40 is provided at the head end side of the piping system 10, a winch 42 is fixed at the end of the working platform 40 away from the piping system 10, and the casing 30 is arranged at the end of the piping system 10 On the side of the end and above the shell 30, there is a walking crane 31 that naturally suspends the shell 30. The horizontal centerline of the shell 30 coincides with the horizontal centerline of the piping system 10. The working platform 40 is fixed with a rope limiter 45 , the first traction rope 43 stretched out from the rope outlet of the winch 42, the first traction rope 43 passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com