Engine hood made from composite material

A technology of engine hatches and composite materials, applied in the direction of upper structure, upper structure sub-assembly, layered products, etc., can solve the problems of restricting the large-scale application of ordinary mass-produced cars and the high cost of carbon fiber materials, and achieve weight reduction, The effect of reducing fuel consumption and reducing emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

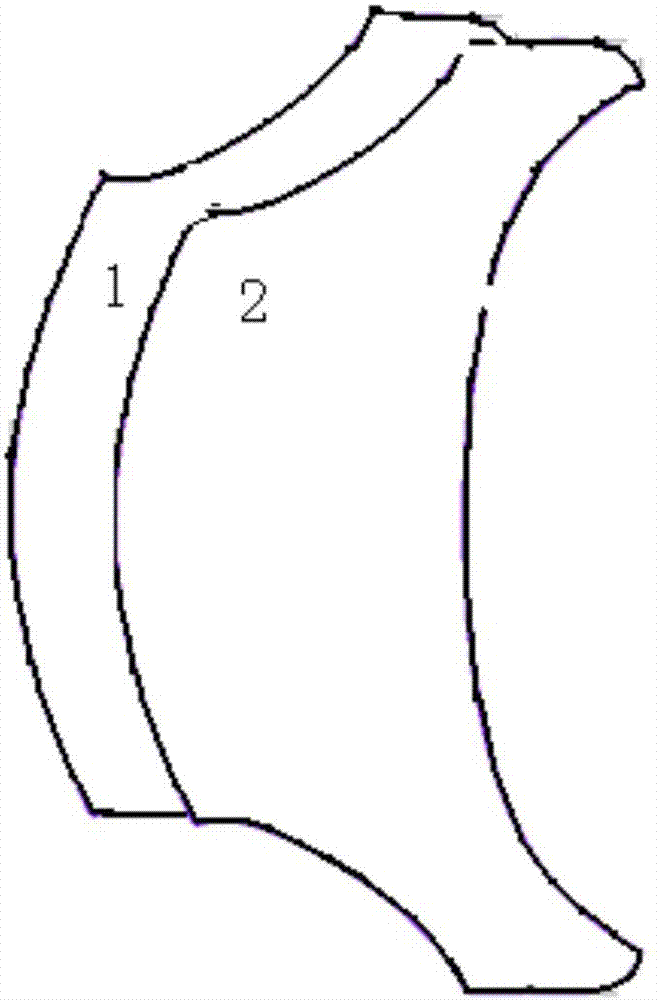

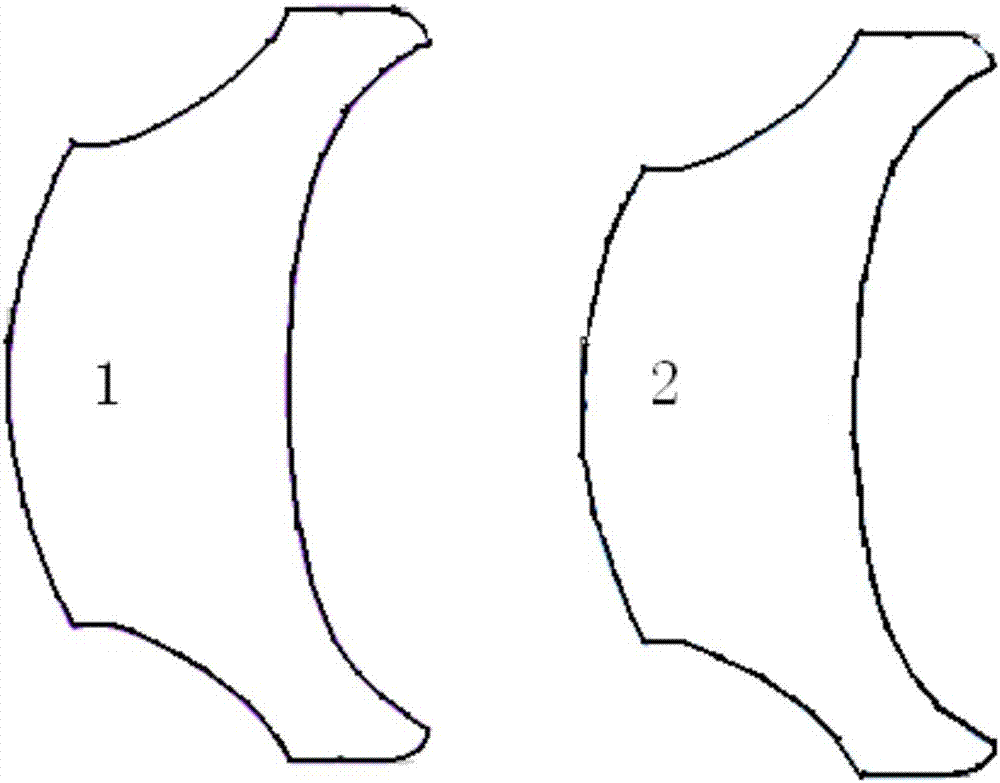

[0022] see Figure 1-2 ,

[0023] The carbon fiber is made of Dalian Xingke 3K twill fabric, (the layering method is one layer of carbon fiber plus one layer of glass fiber, the outermost layer 1 or two are carbon fiber layers, there are eight layers of carbon fiber layers, seven layers of glass fibers, and the sequence of carbon fiber layers is 0 / 90 / 0 / 90 / 0 / 45 / -45 / 0), the resin is Momentive R135 epoxy resin, the curing agent is Momentive H1366, and the car carbon fiber hood outer panel and glass fiber are made by vacuum hot pressing The inner panel (7 layers in total) is glued with polyurethane adhesive to obtain the hair cover 1;

Embodiment 2

[0025] The carbon fiber is selected from Dalian Xingke 3K twill fabric, (the layering method is 0 / 45 / 90 / 45 / 0 / -45 / 90 / 0), the resin is selected from Momentive R135 epoxy resin, the curing agent is Momentive H1366, and vacuum is used The hot pressing method makes the automobile carbon fiber hair cover outer plate and the glass fiber inner plate (7 layers), and adopts polyurethane adhesive glue to obtain the hair cover 2;

Embodiment 3

[0027] The carbon fiber is selected from Dalian Xingke 3K twill fabric, (the layering method is one layer of carbon fiber plus one layer of glass fiber, the outermost layer 1 or two are carbon fiber layers, there are eight layers of carbon fiber layers, seven layers of glass fibers, and the sequence of carbon fiber layers 0 / 45 / 90 / 45 / 0 / -45 / 90 / 0), the resin is Momentive R1564 epoxy resin, the curing agent is Momentive H3458, and the car carbon fiber hair cover outer panel and glass are made by vacuum hot pressing Fiber inner panel (7 layers), glued with polyurethane adhesive to obtain hair cover 3;

[0028] The obtained hair caps are compared with metal hair caps as shown in the table below:

[0029] serial number

Mass(Kg)

Rigidity(N / mm)

hair cover 1

7.8

303

hair cover 2

7.5

331

hair cover 3

8.2

279

metal hair cap

22.4

233

[0030] Glass fiber is an inorganic non-metallic material with excellent performan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com