Unidirectional high-precision meshed-transmission toothed chain board for conveying chains

A high-precision, conveyor chain technology, applied in the field of chain transmission, can solve the problems of large shock and vibration, low transmission efficiency, unsuitable for conveyor chains, etc., and achieve the effect of improving service life, prolonging service life and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

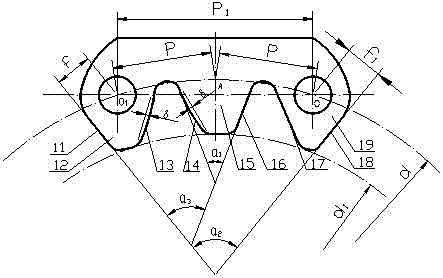

[0013] The chain plate has double pitch on the meshing line, and three teeth are distributed on each chain plate. The 11th tooth profile of the first tooth is a straight tooth profile, and the apothem is the apothem f of the standard toothed chain chain plate. , the 18th tooth profile of the third tooth is a straight line tooth profile, and the apothem f 1 It is 0.96~0.98 times of the center distance f of the chain plate of the standard toothed chain, the 17th tooth profile is a non-working arbitrary curved tooth profile, the 16th tooth profile of the second tooth is a straight line tooth profile, and the half angle of the tooth shape is α 1 / 2=β, the 13 tooth profile of the first tooth and the 14 tooth profile of the second tooth are convex curves, the protrusion δ=0.01f~0.03f, the meshing positioning angle α 3 =60°, profile angle α 2 =2φ+2β, chain plate meshing circle diameter d=p / sin(180° / Z), chain plate addendum circle diameter d 1 =d-2h 1 , where β is the cogging angle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com