Laterite nickel ore processing method

A technology of laterite nickel ore and a treatment method, applied in the metallurgical field, can solve the problems of high cost, long process flow, large energy consumption and the like, and achieve the effects of improving nickel extraction efficiency, short process flow and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

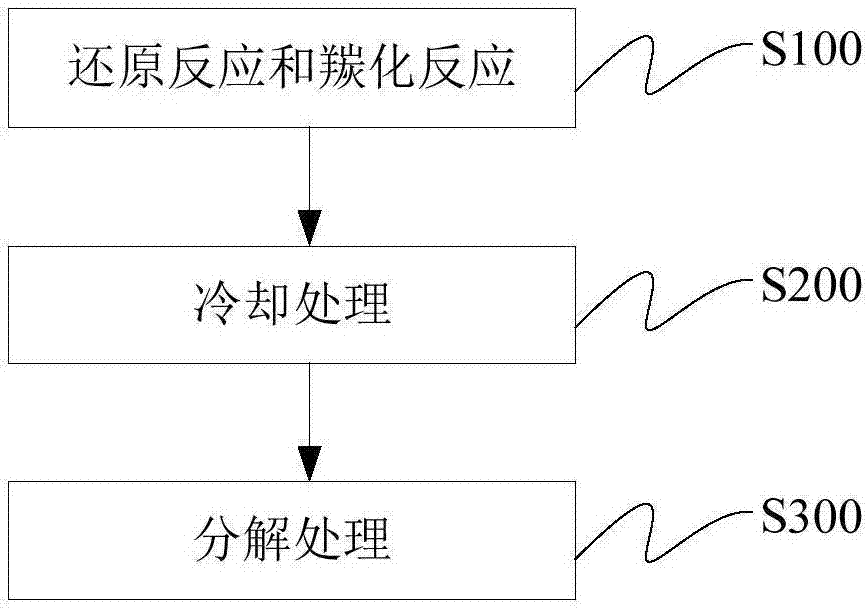

[0019] First refer to the following figure 1 The laterite nickel ore treatment method of the embodiment of the present invention is described.

[0020] The laterite nickel ore processing method according to the embodiment of the present invention comprises:

[0021] S100: reduction reaction and carbonylation reaction

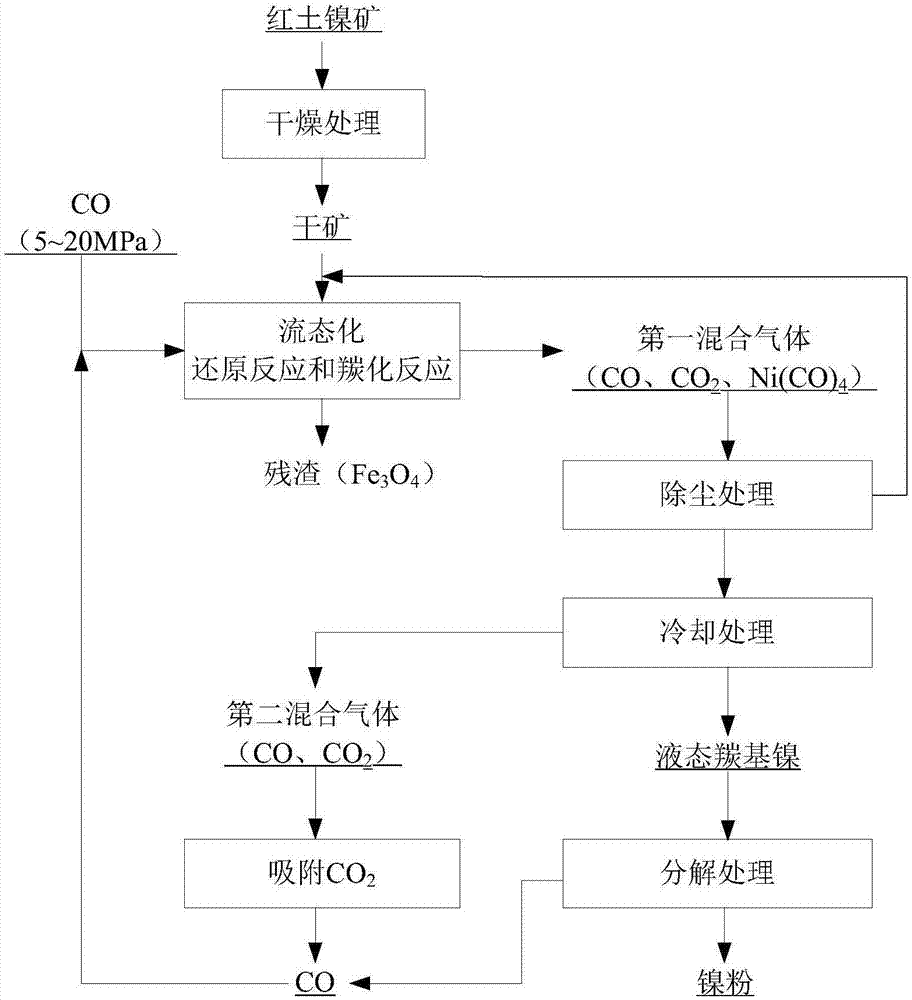

[0022] According to a specific embodiment of the present invention, firstly, the laterite nickel ore is contacted with carbon monoxide in a fluidized bed to perform reduction reaction and carbonylation reaction, so as to obtain the first mixed gas and the residue containing ferric oxide. Wherein, the first mixed gas is a mixed gas of carbon monoxide, carbon dioxide and nickel carbonyl.

[0023] According to a specific embodiment of the present invention, in the fluidized bed, the iron in the laterite nickel ore is firstly reduced by carbon monoxide to finally generate ferric oxide, and the nickel oxide is reduced to generate nickel element, and further, the ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com