Side-mounted lens set and mounting method thereof

An installation method and mirror group technology, applied in the field of mirror groups, can solve problems such as inconvenient assembly of springs, unfavorable engineering, poor controllability of lens eccentricity and inclination, etc., so as to improve precision, avoid concentrated force, and ensure stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

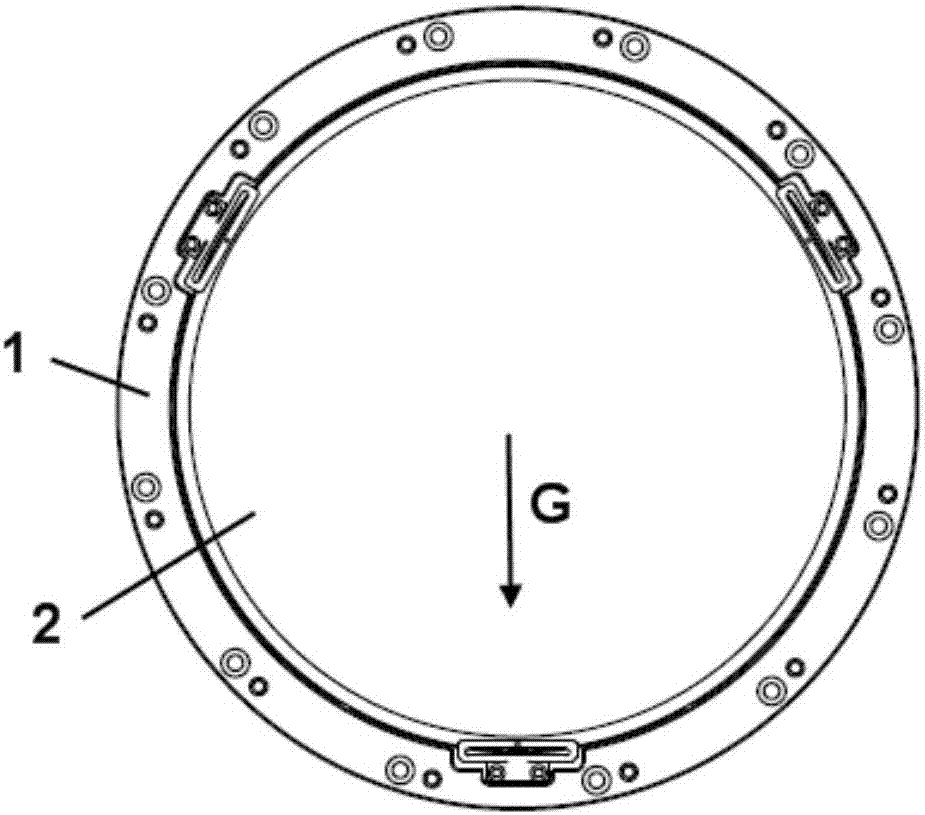

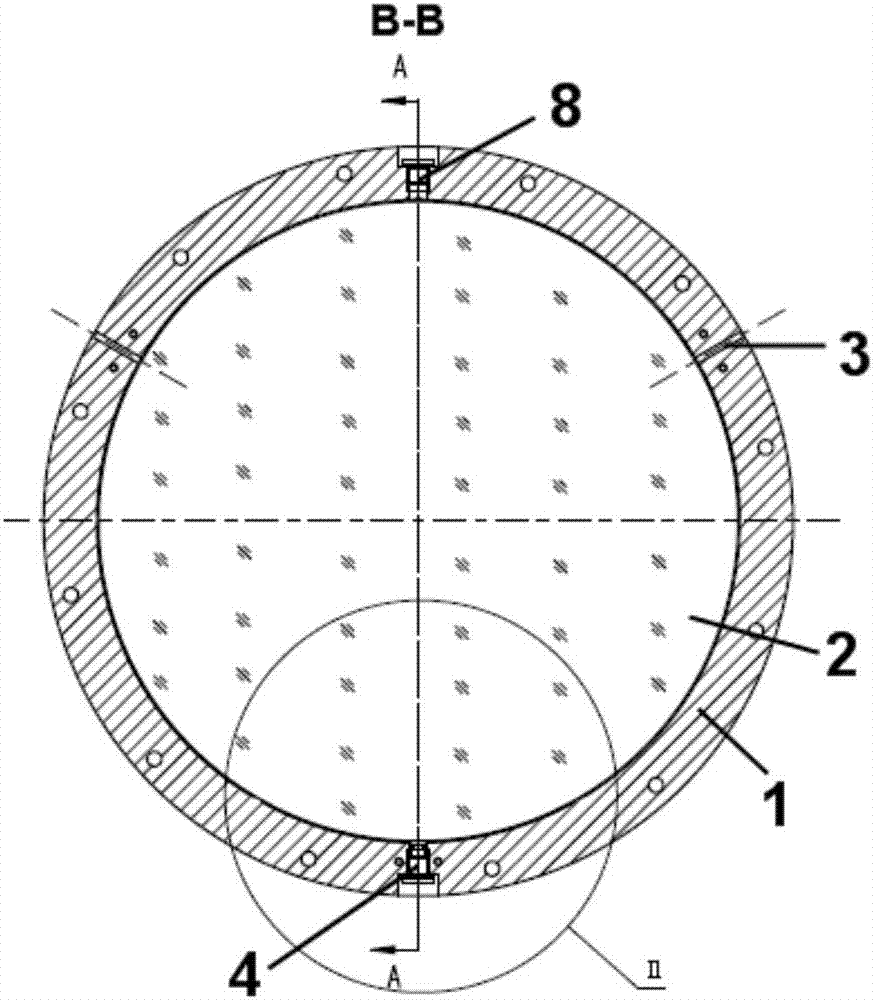

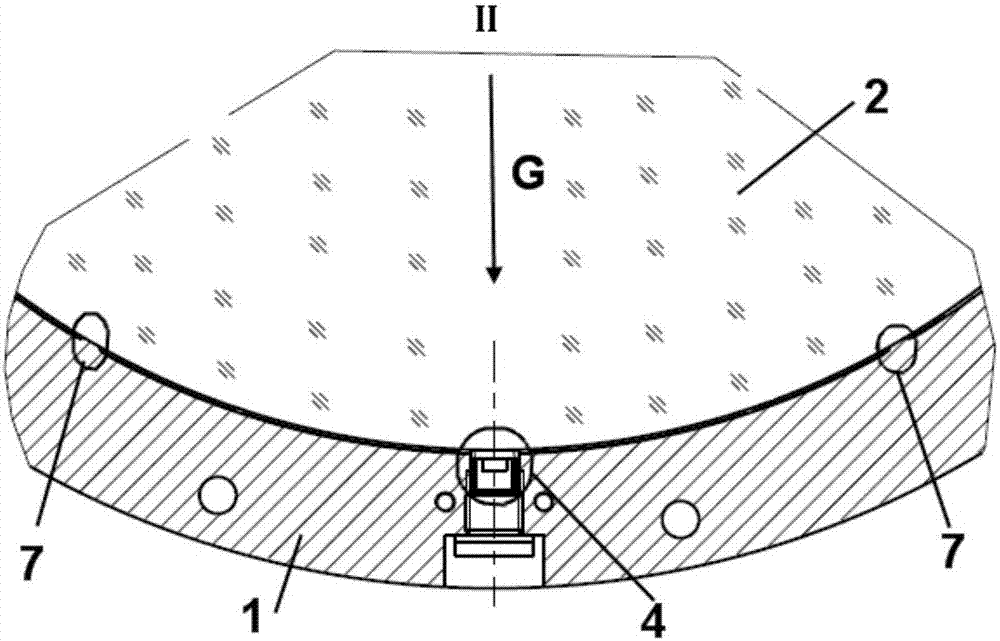

[0041] Please refer to Figure 1-5, the present embodiment 1 provides a side-standing lens group, including a side-standing picture frame 1, side-standing optical lenses 2 installed in the picture frame 1, and symmetrically distributed on both sides of the vertical center line of the picture frame 1 and The picture frame 1 is integrally formed with two hard support points 7, and each of the hard support points 7 is located below the horizontal centerline of the picture frame 1, and each of the hard support points 7 is connected to the optical The lens 2 is directly contacted and connected; an elastic support member 4 is arranged directly below the bottom of the optical lens 2, and the elastic support member 4 is contacted and connected through an adjustment screw 10 penetrating directly below the bottom of the frame 1; A compression screw 8 for limiting radial displacement of the optical lens 2 runs through the top of the mirror frame 1 .

[0042] In the side-standing lens gr...

Embodiment 2

[0048] Embodiment 2 provides a method for installing the side mirror group of Embodiment 1, including the following steps:

[0049] Step S1, setting the mirror frame 1 sideways;

[0050] Step S2, placing the optical lens 2 sideways on the hard support body 5 of the frame 1;

[0051] Step S3, by pressing the screw 8 to apply a force of the size of the gravity G of the optical lens 2 to offset the optical lens 2 against each hard support point 7, so as to limit the radial displacement of the optical lens 2;

[0052] Step S4, use a dynamometer to adjust the supporting force of the elastic support member 4 to support the optical lens 2, and make the supporting force equal to 1 / 3 of the gravity G of the optical lens 2, and tighten the adjusting screw 10;

[0053] Step S5, install more than one pre-tension reed 6 as required, and measure the force of the pre-tension reed 6 to make it equal to 2 / 3 of the gravity G of the optical lens 2;

[0054] Step S6, dispensing glue through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com