Fuzzy mode identification-based blast furnace hot-blast stove energy consumption state multi-dimension assessment method

A technology of fuzzy pattern recognition and hot blast stove, which is applied in the field of metallurgy, can solve the problems of heat dissipation loss and smoke exhaust loss that can only be estimated, not comprehensive enough, and inaccurate, and achieve objective and true evaluation results, comprehensive evaluation results, and rich sample sets Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

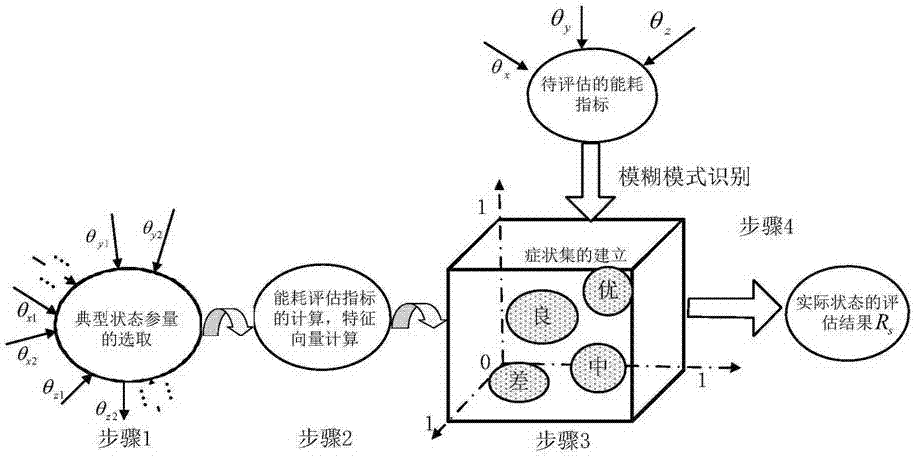

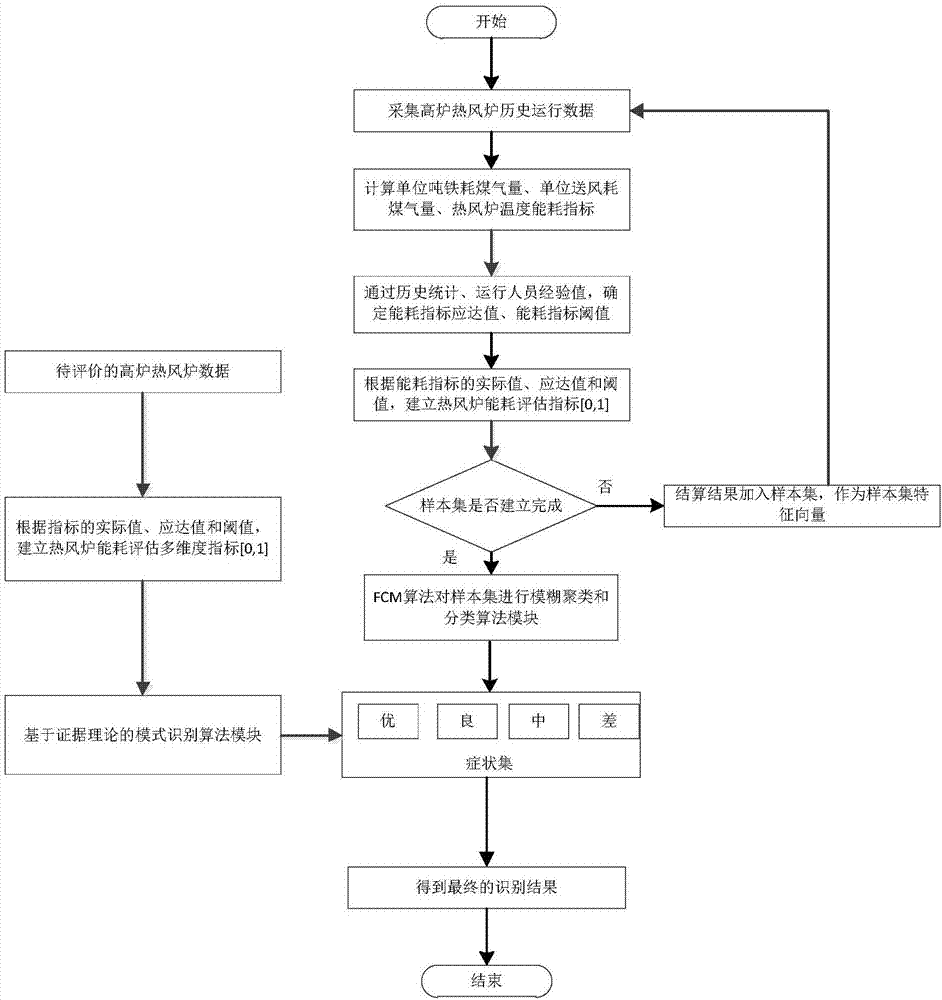

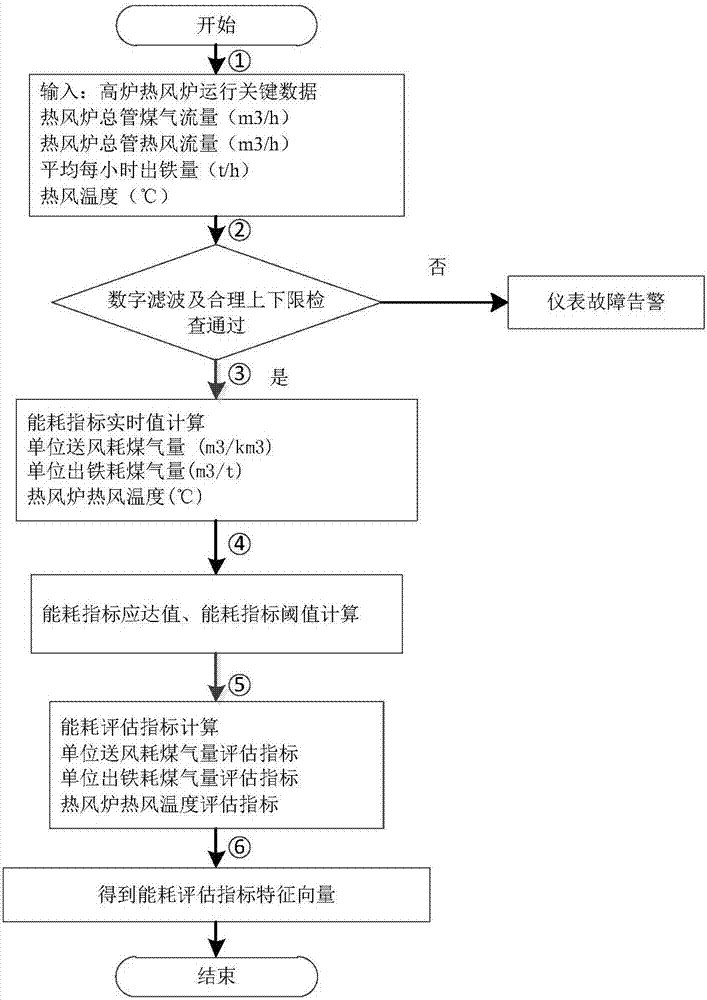

[0052] The present invention provides a multi-dimensional evaluation method for the energy consumption status of blast furnace hot blast stoves based on fuzzy pattern recognition, combining the historical operation data and real-time operation data of blast furnaces and hot blast stoves, and according to the selected multi-dimensional indicators, the comprehensive energy consumption status of the hot blast stove system is calculated. out assessment. The evaluation results are used to guide the production operation, and the operation status is assessed. The evaluation method algorithm model is as follows: figure 1 As shown, the specific implementation process is as follows figure 2 Shown:

[0053] Step 1: Selection of typical state parameters. The purpose of the present invention is to evaluate the energy consumption state of the hot blast stove. Therefore, it is necessary to select typical state parameters that can reflect the energy consumption of the hot blast stove, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com