Metal high current connector

A high-current connector, metal technology, used in vehicle connectors, connections, parts of connecting devices, etc., can solve the problems of poor connector shielding performance, large connector size, and mechanical tolerance inspection, and achieve overload. Large capacity, small size, and the effect of improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

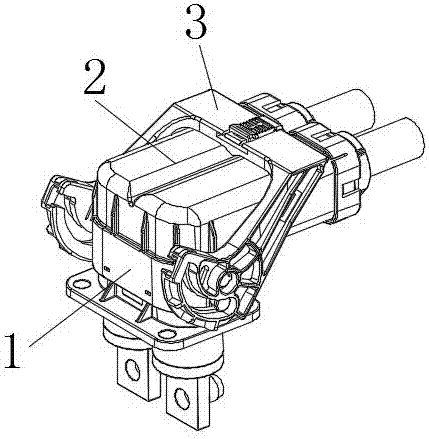

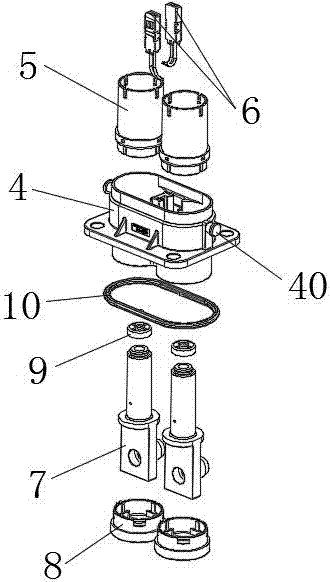

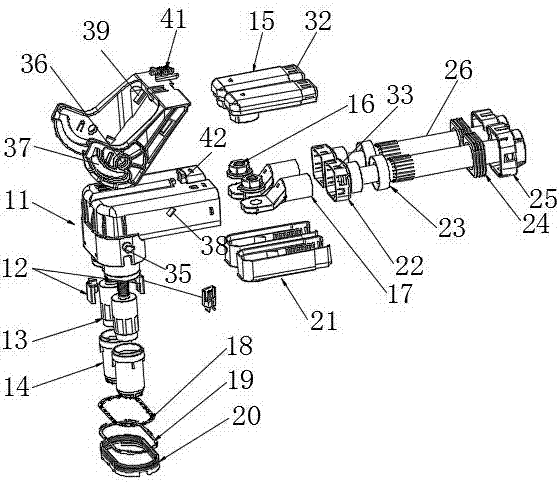

[0040] Such as Figure 1-21 It is a structural schematic diagram of the present invention, a metal high-current connector, including a socket assembly 1, a plug assembly 2 and a locking device 3, a PIN needle 7 is inserted into the through hole of the socket body 4 of the socket assembly 1, and a PIN needle 7 in the socket body 4 Insert the high-voltage interlock female terminal 6 into the insertion groove, insert the crown spring contact assembly 13 into the through hole of the plug body 11 of the plug assembly 2, and insert the high-voltage interlock male terminal 12 into the insertion groove of the plug assembly 2, and the crown spring contact The threaded column at the end of the component 13 passes through the through hole on the lug 17 and then tightens the connection with the anti-loosening nut 16. The front shield contact spring 18, the front spring retaining ring 19 and the front waterproof ring are sequentially snapped into the plug body 11. 20.

[0041] This metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com