High capacity air-cooled static var generator power unit structure

A static reactive power and power unit technology, applied in reactive power adjustment/elimination/compensation, reactive power compensation, electrical components, etc., it can solve problems such as heavy workload, water seepage, and high reliability requirements, and achieve heat dissipation. , to ensure the effect of electrical parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

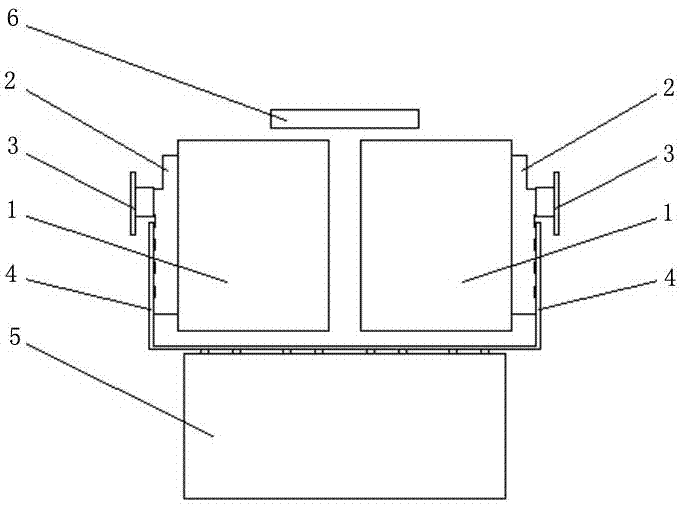

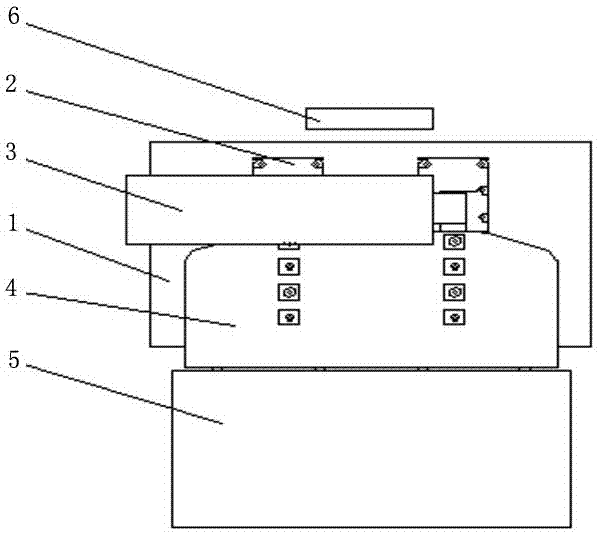

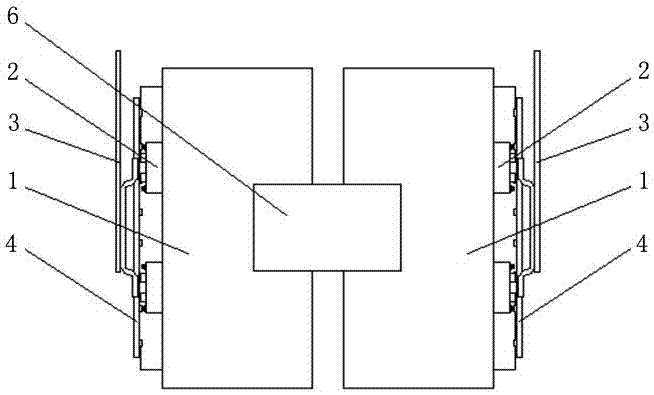

[0024] Figure 1 to Figure 5 It shows an embodiment of the power unit structure of the large-capacity air-cooled static var generator of the present invention, including two heat pipe radiators 1 arranged at intervals, and the two heat pipe radiators 1 are equipped with unit The circuit bridge arm 2, each unit circuit bridge arm 2 is connected with an AC output bar 3, and the two unit circuit bridge arms 2 are connected together with a DC laminated output busbar 4 enclosed to the bottom of the two heat pipe radiators 1, and the DC laminated output busbar 4 is connected to the bottom of the two heat pipe radiators. A capacitor component 5 is installed at the bottom of the layer output busbar 4 . In this structure, two heat pipe radiators 1 are used for air cooling and heat dissipation, which can effectively realize the heat dissipatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com