Self-excited vibration generator for oil and gas pipeline monitoring system

A monitoring system, self-excited vibration technology, applied in the direction of generators/motors, piezoelectric effect/electrostrictive or magnetostrictive motors, electrical components, etc., can solve the problems of electromagnetic interference, cut-off, and large volume of power generation devices , to achieve the effects of strong fluid adaptability, improved reliability, and strong power generation capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

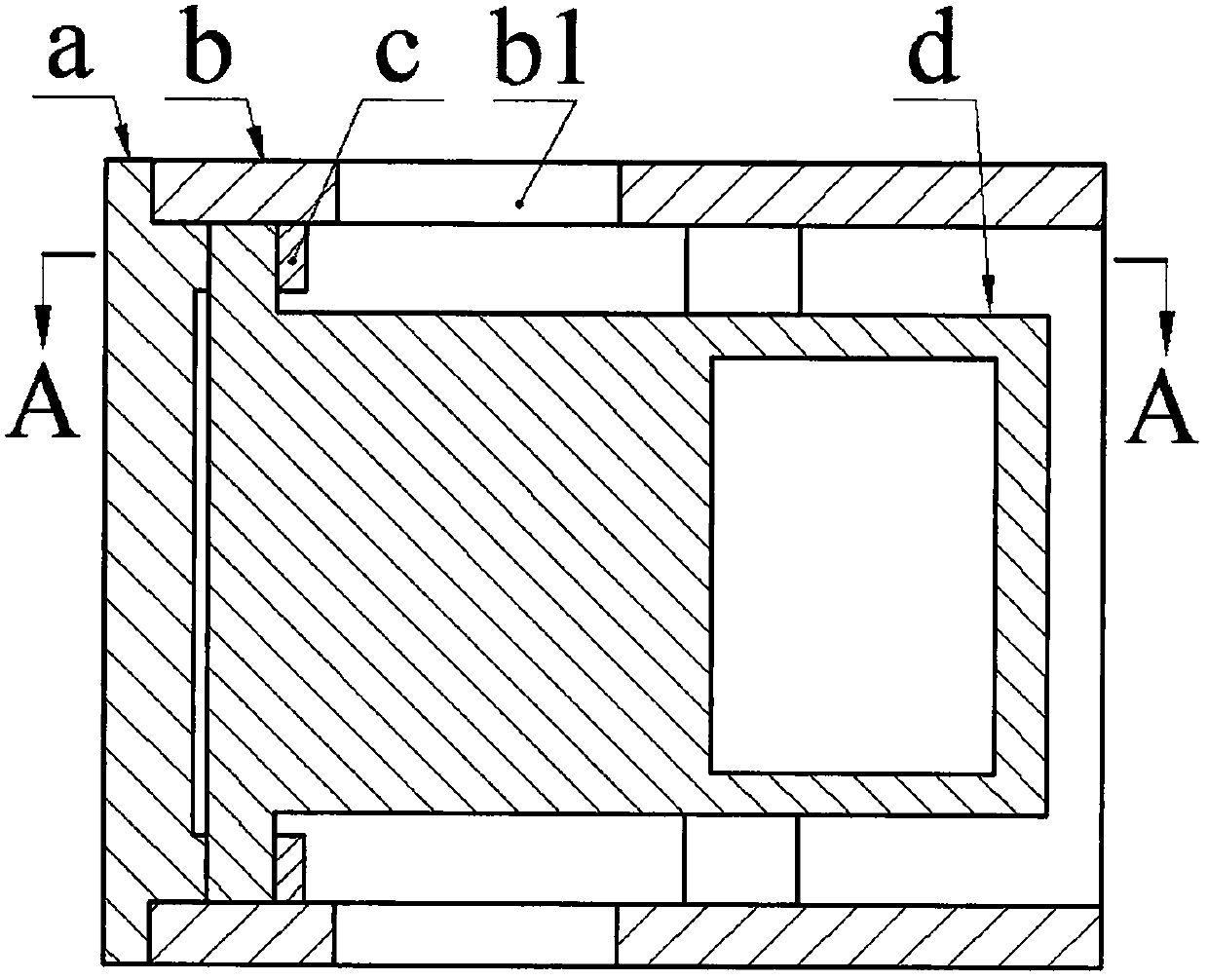

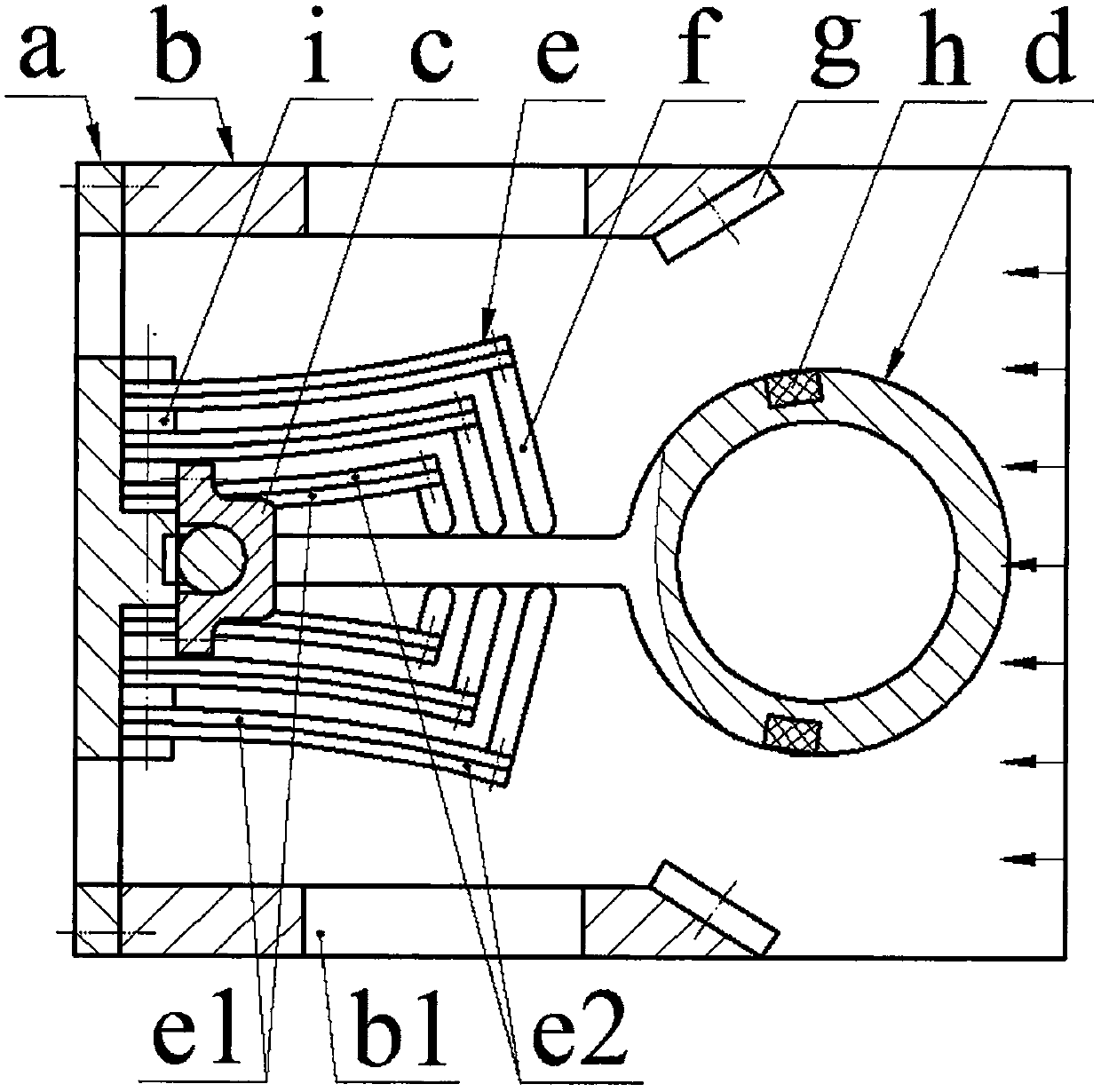

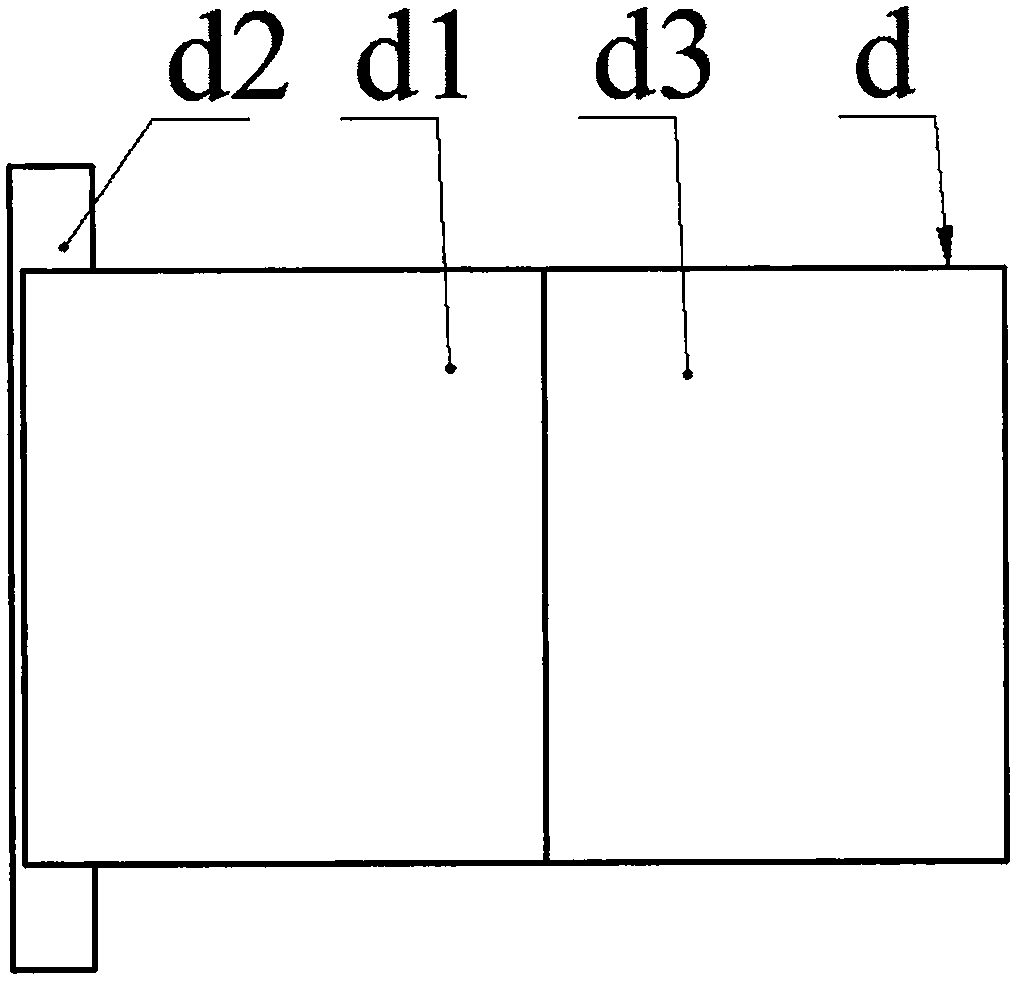

[0012] The casing b is provided with a flow hole b1, and the end is installed with a vertical plate a through screws. The vertical plate a is provided with a flow hole a1 and a boss a2. Piezoelectric vibrator e; when the number of piezoelectric vibrators e installed on one side of the boss a2 is greater than 1, a gasket i is crimped between the fixed ends of two adjacent piezoelectric vibrators e; the piezoelectric vibrator e is formed by the substrate e1 It is bonded with the piezoelectric sheet e2, and the substrate e1 of the piezoelectric vibrator e on both sides of the boss a2 is installed close to it; the other end of the piezoelectric vibrator e is installed with a top block f through screws, and the top block f is placed on the side of the piezoelectric vibrator e On one side of the base plate e1, the other end of the top block f leans against the rocker d1 of the exciter d; one end of the rocker d1 is provided with a hollow turbulent body d3, and the other end is provid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com