Picture compression method in AOI (Automatic Optic Inspection) detection system and display panel defect detection system

A technology for displaying panel defects and compression methods, applied in image analysis, image communication, image data processing, etc., can solve problems such as resource consumption, image lossy compression, image data loss, etc., to reduce information volume, improve compression rate, The effect of reducing compression time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with specific embodiment the present invention is described in further detail:

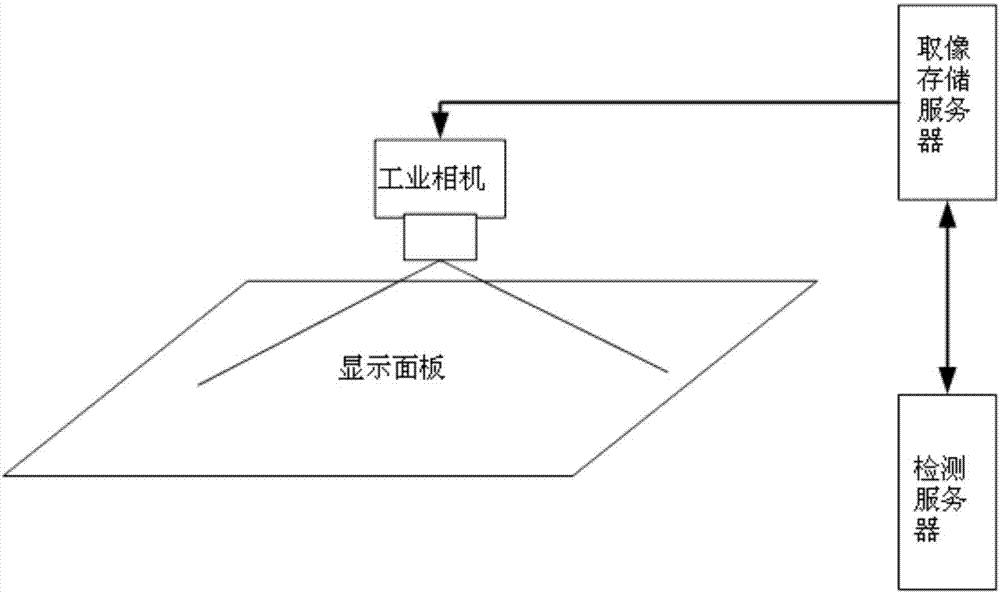

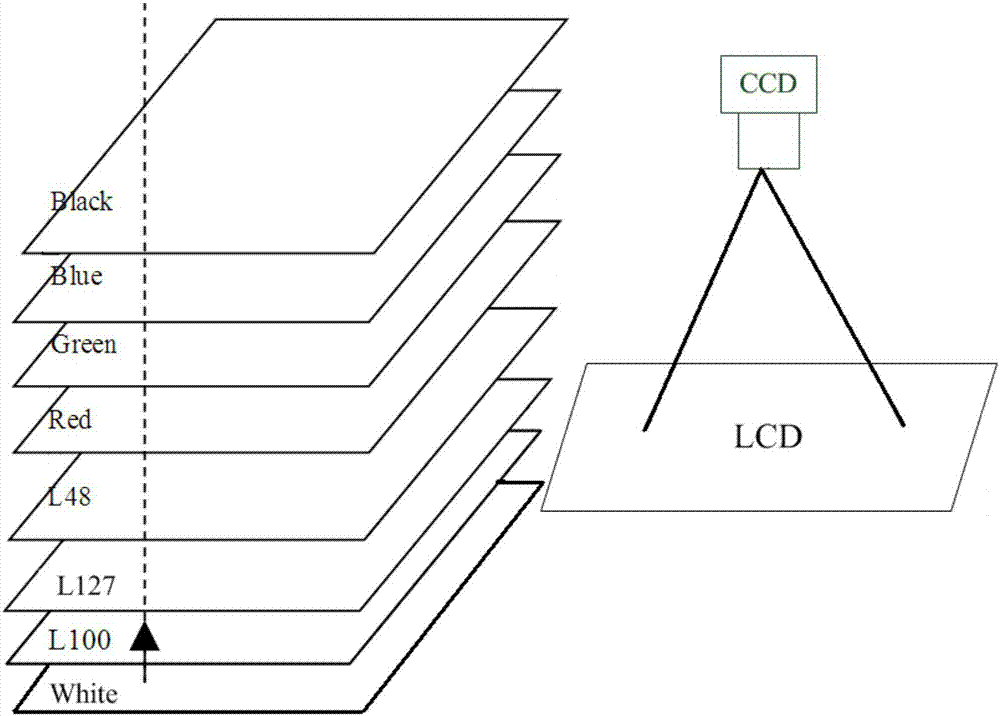

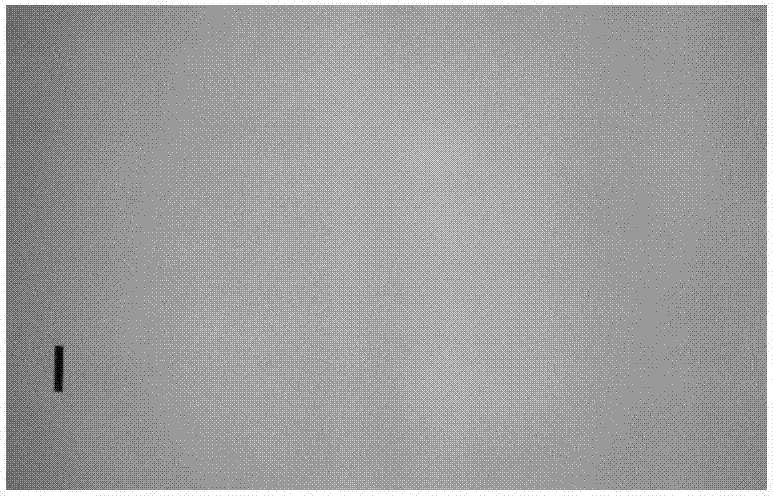

[0024] For the AOI defect detection of the display panel, it is generally necessary to take multiple defect detection images of the display panel, such as figure 2 As shown, in the process of taking each display panel defect detection image, the relative position between the camera and the display panel does not change, so the difference between different display panel defect detection images captured by each camera is relatively small, These differences are often caused by the defects of the display panel itself. Using the pure white detection image as the background, and subtracting the pure white image from the rest of the images, a large amount of repetitive information can be removed and key effective information can be retained.

[0025] Based on the same camera, images taken by cameras under different display panel defect detection images are very similar. The p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com