Slow cooker with lock catch structures

A slow cooker and locking technology, which is applied to the structure of cooking utensils, cooking utensil lids, cooking utensils, etc., can solve the problems of inconvenient storage and storage, complex locking structure, and increased weight of the lid, so as to save space and maintain overall Simple appearance and improved aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

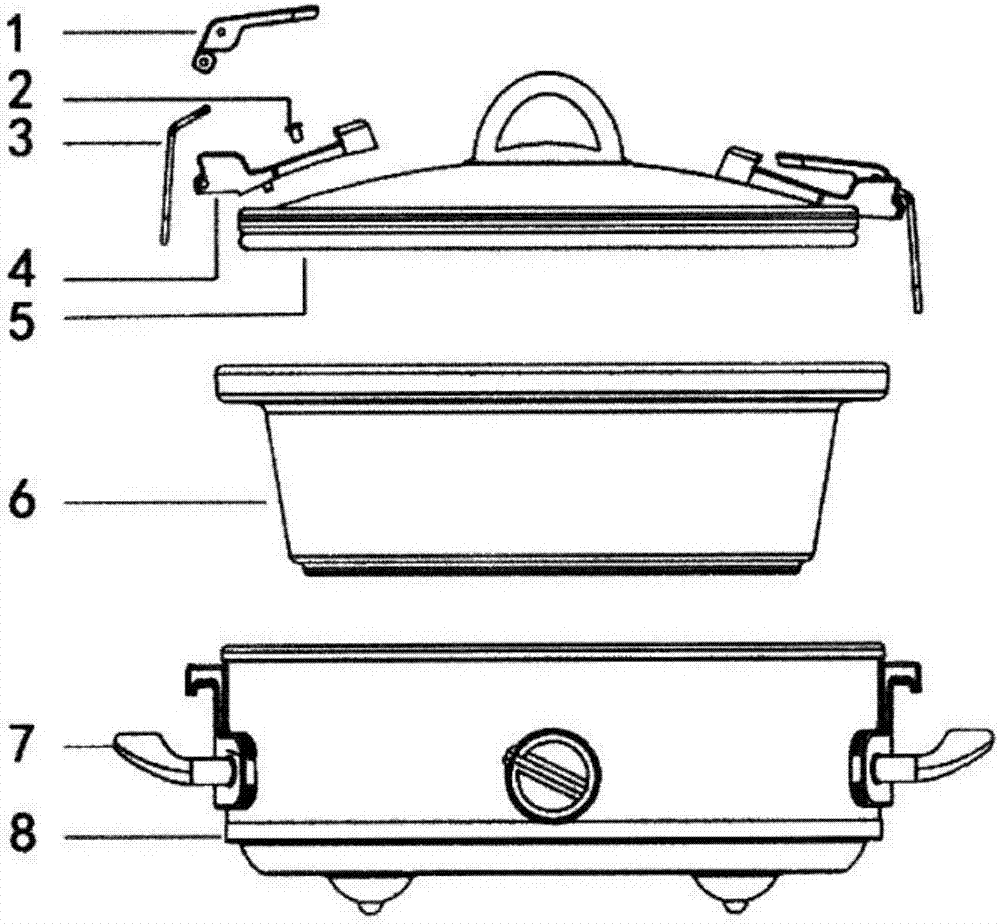

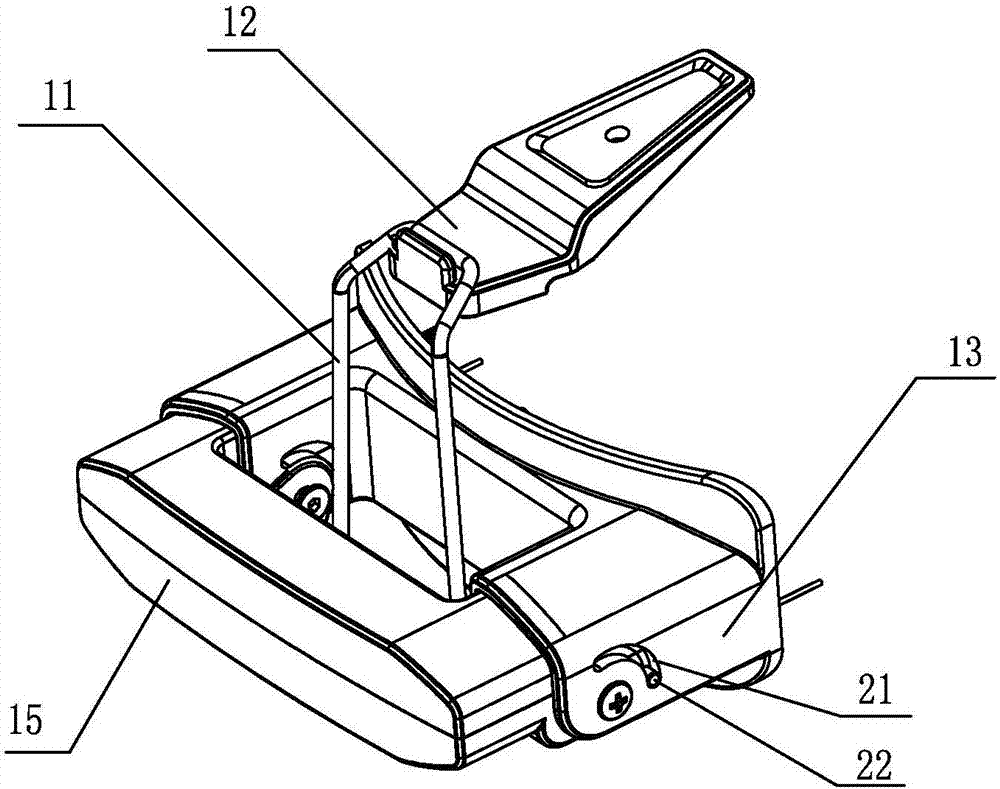

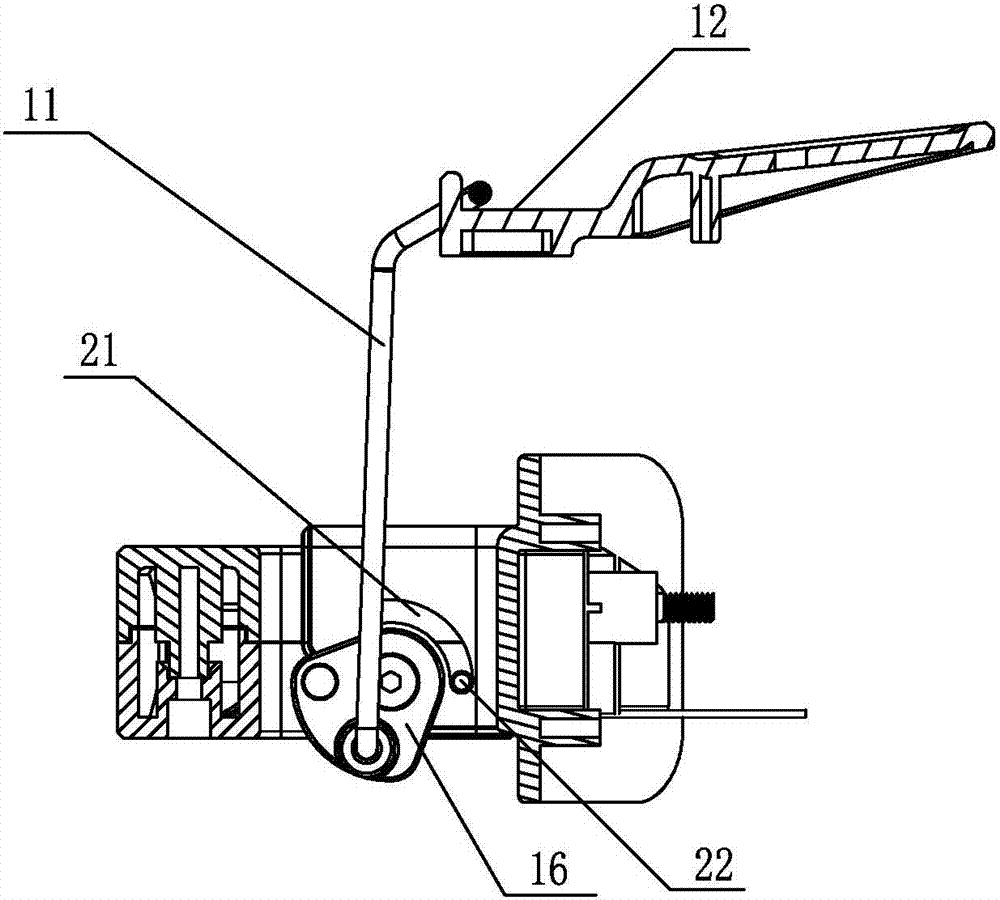

[0033] Embodiment one: see Figure 2-6 As shown, a slow cooker with a lock structure includes a pot body, a pot cover, and handles arranged on both sides of the pot body. Each of the handles is respectively provided with a lock structure, and the lock structure includes The clasp 11 installed on the handle, and the clasp 12 arranged on the pot cover, one side of the clasp 11 is an open end, and the other side is a closed end snap-fitted with the clasp 12; The handle includes a fixed portion 13 connected to the pot body, and a folding portion 15 connected to the fixed portion 13 through a rotating shaft 14. A cam mechanism 16 is provided on the rotating shaft 14 of the folding portion 15. The opening of the buckle 11 The end is arranged on the follower of the cam mechanism 16, so that there are two states of locking and unlocking between the clasp 11 and the clasp 12.

[0034] In this embodiment, the buckle 11 is formed by bending a steel wire, and its open ends are respective...

Embodiment 2

[0041] Embodiment two: see Figure 7-9 As shown, a slow cooker with a locking structure, the structure of this embodiment is basically similar to the first embodiment, the difference is that a safety lock 23 is provided in the folding part 15, and the safety lock 23 includes Support 24, spring 25 and button 26, described support 24 front end is provided with lock hole 27, is provided with the dead tongue (not drawn) that cooperates with lock hole 27 in described fixed part 13, and the middle part of described support 24 is provided with a The pressing piece 28 , one end of the spring 25 abuts against the pressing piece 28 , and the other end abuts against the button 26 , and the button 26 protrudes from the outer surface of the folding portion 15 .

[0042] In this embodiment, the cooperation between the clasp 11 and the clasp 12 is the same as that of the first embodiment, the difference is the safety lock 23 for preventing mistaken overturning, such as Figure 9 As shown, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com