Backflow-prevention and smell-resistance hydraulic self-control valve device and application method

A hydraulic self-control and anti-backflow technology, applied in the direction of valve device, valve operation/release device, safety device, etc., can solve the problems of drainage system with many electrical equipment, complicated maintenance and management, and high maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

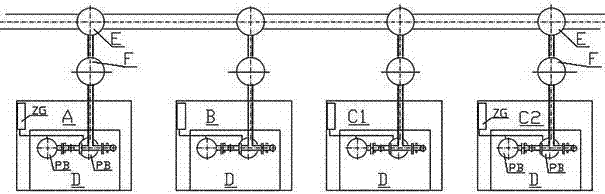

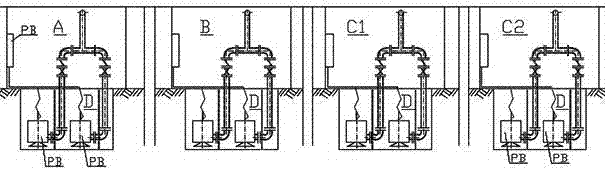

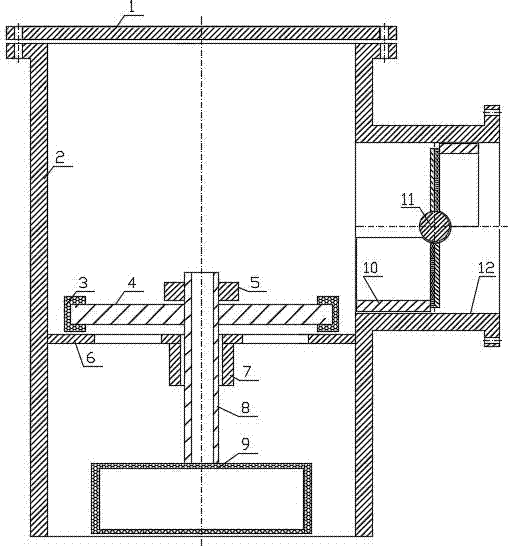

[0020] Below according to accompanying drawing and embodiment the present invention will be described in further detail:

[0021] An anti-backflow and odor-resistant hydraulic self-control valve device, comprising an air shaft main body, a valve body Z, and a communication pipe L. The side wall of the communication pipe L has a pipe interface K, and the pipe interface K is connected to the valve body Z. The valve body Z is a three-way pipe, and the side wall of the vertical pipe 2 has a horizontal pipe 12, and the vertical pipe 2 communicates with the horizontal pipe 12. The inside of the vertical pipe 2 has a cross ring plate 6, and the height of the cross ring plate 6 is lower than that of the horizontal pipe. 12 height, the middle part of the cross ring plate 6 is a cross shape, the lower part of the cross ring plate 6 is connected to the limit pipe 7, the upper part of the cross ring plate 6 is connected to the disc 4, and the outer side of the disc 4 is connected to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com