Gas micro-leakage detection device and method for a sealing device

A sealing device and leakage detection technology, which is applied in the direction of fluid tightness testing, measuring devices, liquid tightness measurement using liquid/vacuum degree, etc. It can solve the problems that the test accuracy is not high enough, and the leakage value cannot be given, etc. , to achieve the effect of simple structure, easy implementation and high test accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

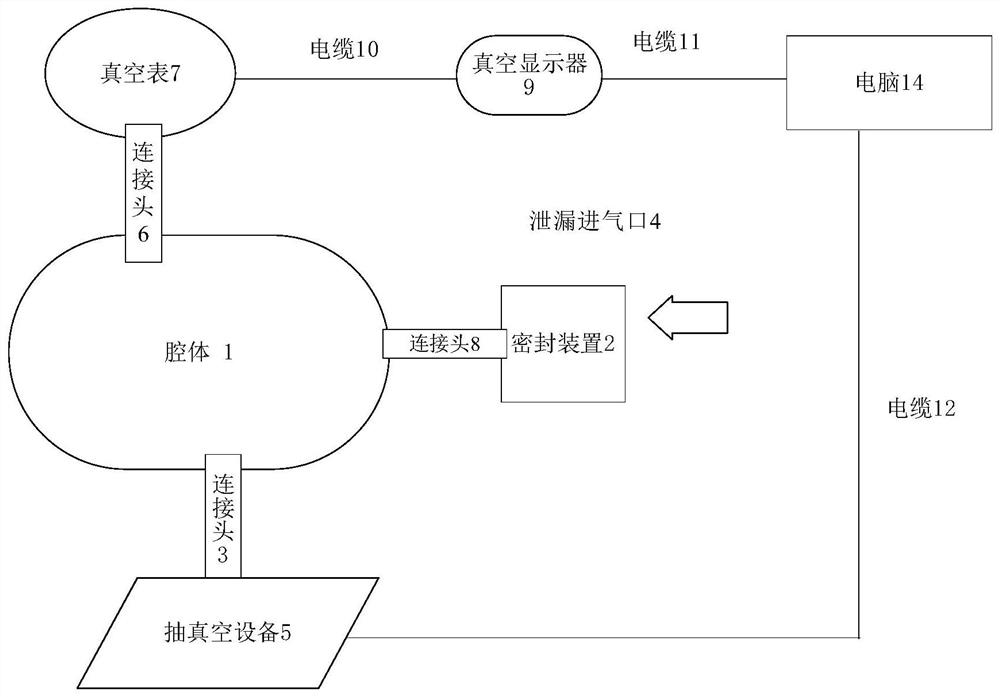

[0030] Such as figure 2 As shown, a sealing device gas microleakage detection device disclosed in this embodiment includes a cavity 1 , a sealing device 2 , a vacuuming device 5 , a vacuum gauge 7 , a vacuum display 9 and a computer 14 . The vacuum gauge 7 and the vacuum display 9 adopt a microcomputer digital display composite vacuum gauge produced by Chengdu Zhenghua Electronic Instrument Co., Ltd., and the serial number is ZDF-X-LED. The cavity 1 and the sealing device 2 are connected through a connecting joint 8 , the cavity 1 and the vacuum gauge 7 are connected through a connecting joint 6 , and the cavity 1 and the vacuum equipment 5 are connected through a connecting joint 3 . The vacuum gauge 7 and the vacuum display 9 are connected by a cable 10 , and the vacuum display 9 and the computer 14 are connected by a cable 11 . There is a cut-off valve on the connecting joint 3 . The vacuum equipment 5 and the computer 14 are connected by cables 12 . The computer 14 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com