Processing and testing device and method of a shale fracture toughness test sample

A fracture toughness and processing device technology, which is applied in the field of processing devices and testing devices for fracture toughness test samples, can solve the problems of difficult steel wires, affecting the accuracy of fracture toughness testing, and the inability to ensure straight saw kerf, etc., to achieve easy processing, high Practical value, easy processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For further elaborating the technical means and effect that the present invention adopts for reaching the intended purpose of the invention, the present invention will be further elucidated below in conjunction with the accompanying drawings:

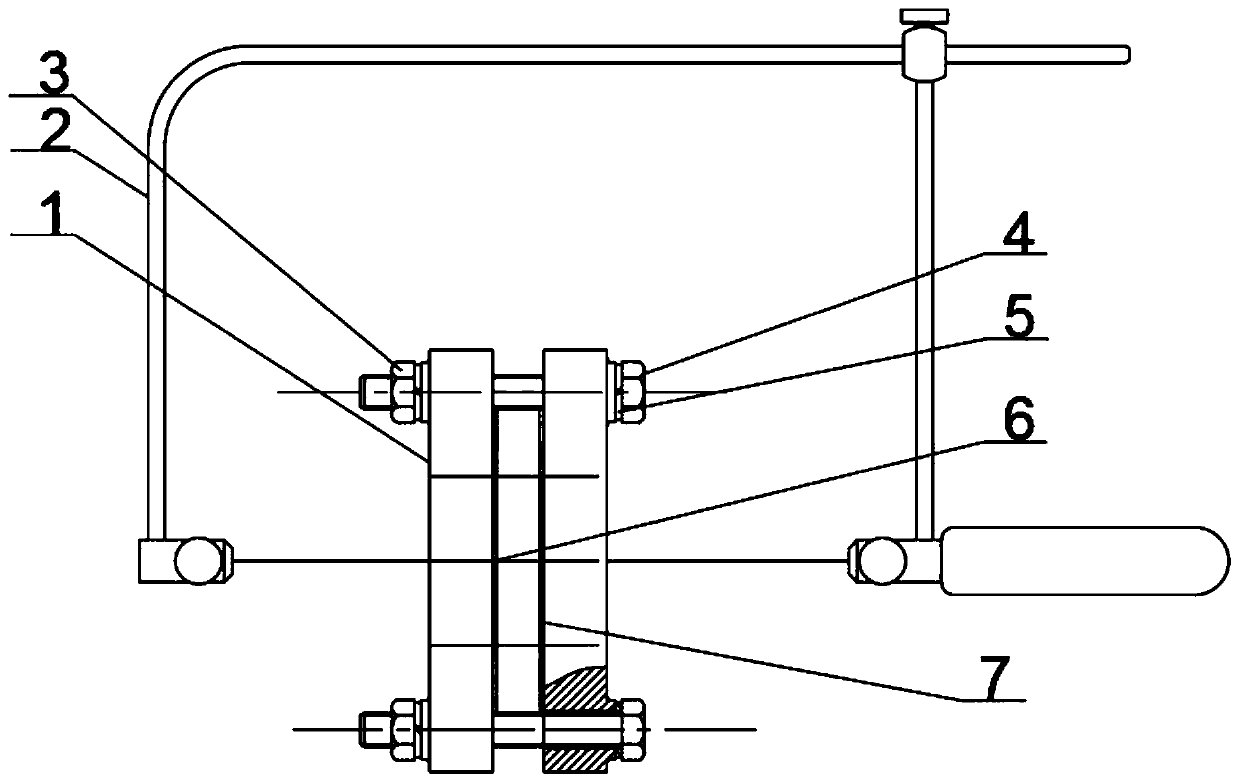

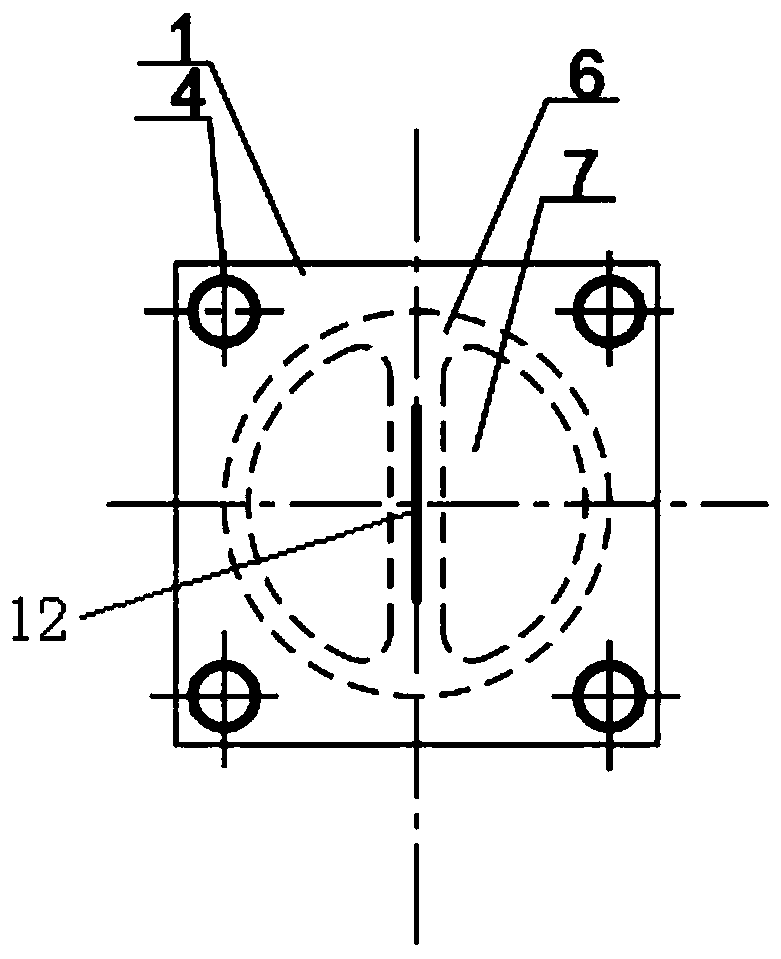

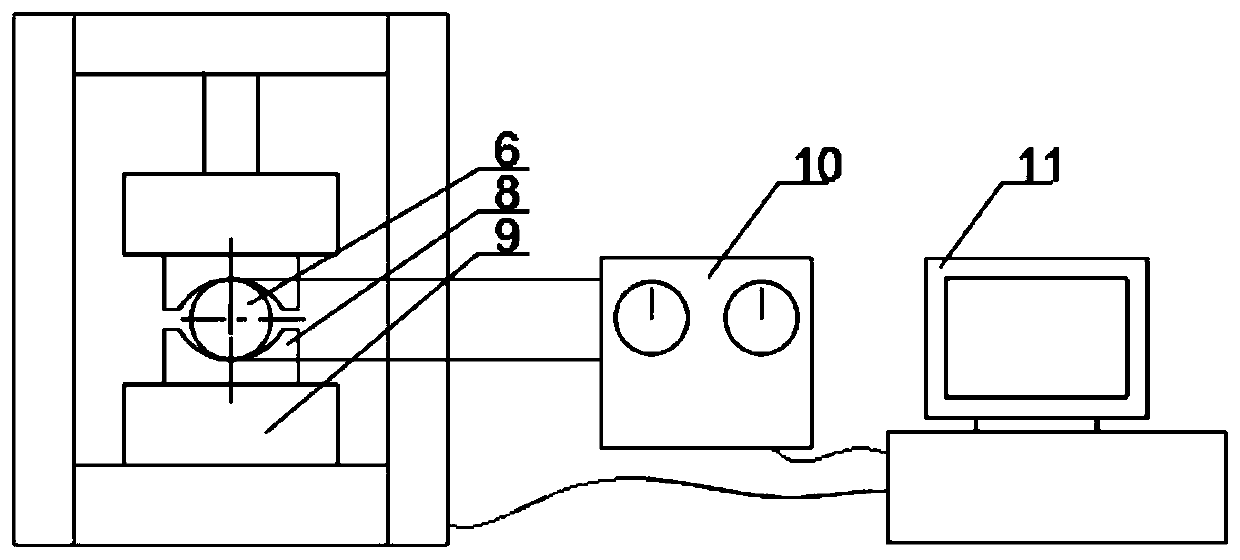

[0050] Such as Figure 1-2 As shown, a processing device for a shale fracture toughness test sample, the processing device includes: the processing device includes: the metal plate clamp 1, a wire saw 2, a rubber pad 7;

[0051] Wherein, the two metal plate fixtures 1 are made of steel, and the shape is a quadrangle, and through holes are arranged on the four corners of the quadrangular shape. The two metal plate fixtures 1 are arranged oppositely, and the two metal plate fixtures 1 are opposite Each surface is provided with a rubber pad 7, and the two metal plate clamps 1 are fixedly connected together by a hexagonal nut 3, a hexagonal bolt 4 and a metal washer 5, thereby clamping the shale core sample 6 on the rubber pad 7; th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com