High-voltage fast recovery diode structure

A technology for recovering diodes and diodes, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., and can solve problems such as poor soft recovery performance and weak current shutdown capability, and achieve improved reverse recovery softness, good process compatibility, and improved The Effect of Area Efficiency and Chip Withstand Voltage Capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

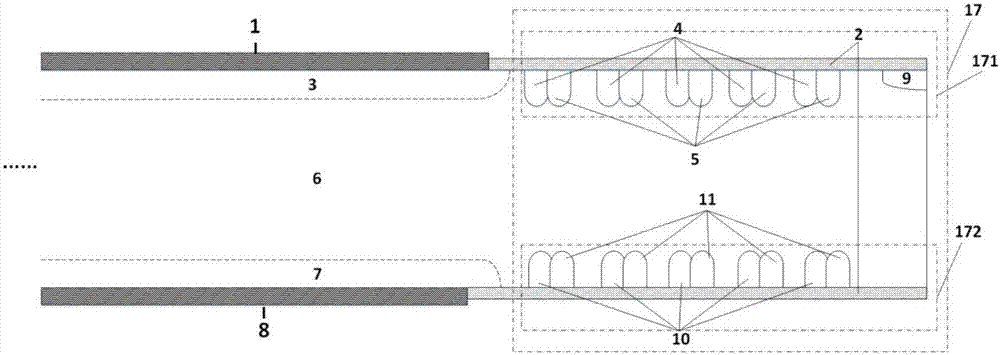

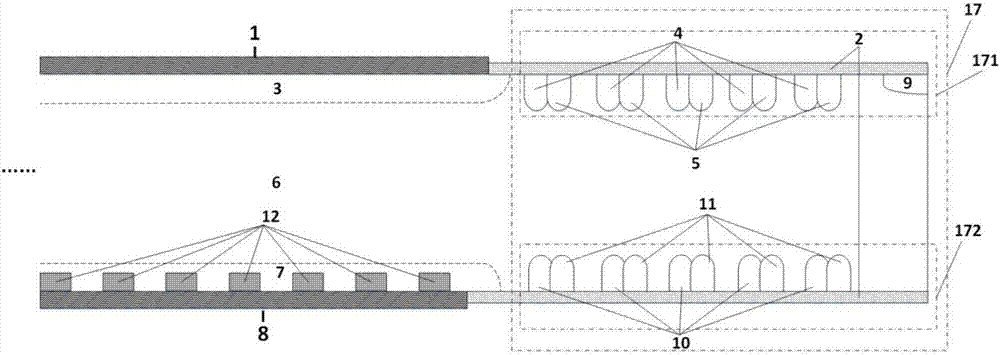

[0034] In this embodiment, the high-voltage fast recovery diode, such as figure 2 As shown, the back local p+ doping region 12 is on the surface of the cathode, and the doping dose is 1×10 15 ~1×10 18 cm -2 , the width is 1-10 μm, the thickness is 1-10 μm, and the arrangement pitch is 1-10 μm. The high-voltage fast recovery diode terminals are all double-sided terminals, including a front terminal area 171 and a rear terminal area 172, respectively surrounding the anode area and the cathode area. The front terminal region 171 is arranged on the anode side of the diode, and includes one of field plates, field limiting rings, semi-insulating thin film layers, and junction terminal extension structures with laterally variable doping, or two or more of them. Combination; the back termination region 172 is arranged on the cathode side of the diode, including one of a field plate, a field limiting ring, a semi-insulating thin film layer, and a junction termination extension stru...

Embodiment 2

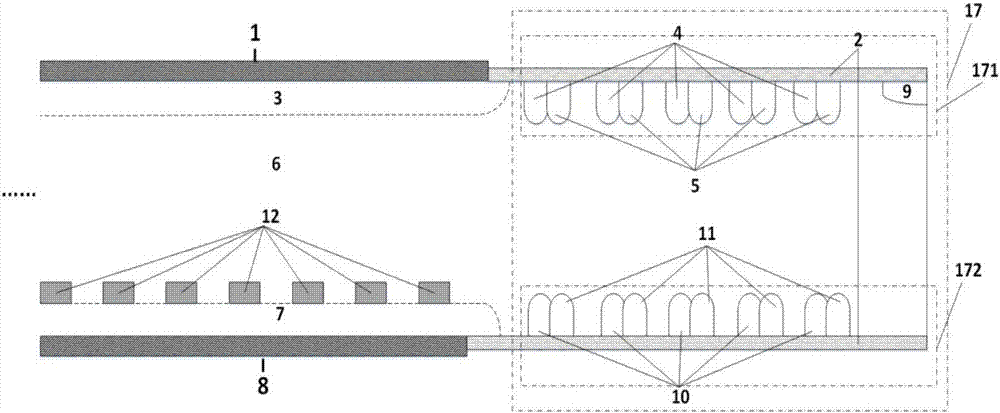

[0036] In this embodiment, the high-voltage fast recovery diode, such as image 3 As shown, the back local p+ doped region 12 is inside the cathode, and the doping dose is 1×10 15 ~1×10 18 cm -2 , the depth to the surface of the cathode region is 1-10 μm, the width is 1-10 μm, the thickness is 1-10 μm, and the arrangement pitch is 1-10 μm. The high-voltage fast recovery diode terminals are all double-sided terminals, including a front terminal area 171 and a rear terminal area 172, respectively surrounding the anode area and the cathode area. The front terminal region 171 is arranged on the anode side of the diode, and includes one of field plates, field limiting rings, semi-insulating thin film layers, and junction terminal extension structures with laterally variable doping, or two or more of them. Combination; the back termination region 172 is arranged on the cathode side of the diode, including one of a field plate, a field limiting ring, a semi-insulating thin film la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com