X-shaped arranged anti-bending support structure and connecting method thereof

A technology of anti-buckling bracing and supporting structure, applied in the direction of earthquake resistance, building components, building structure, etc., can solve the problems of low rigidity and energy consumption efficiency of anti-buckling bracing, occupation of anti-buckling bracing, large residual deformation, etc. Post-repair, reduce the overall residual deformation, the effect of large lateral stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

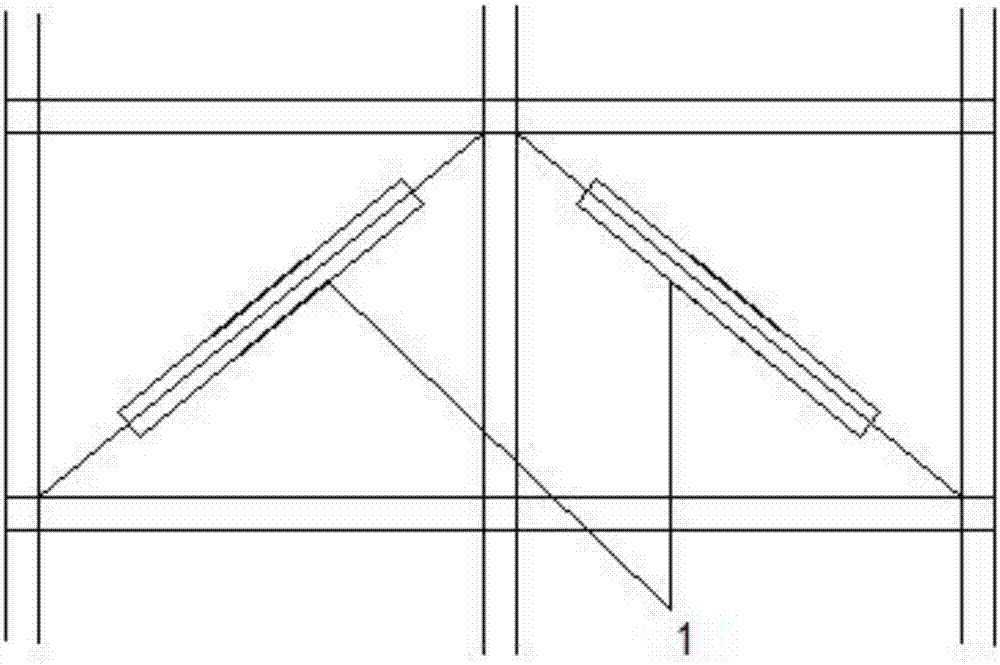

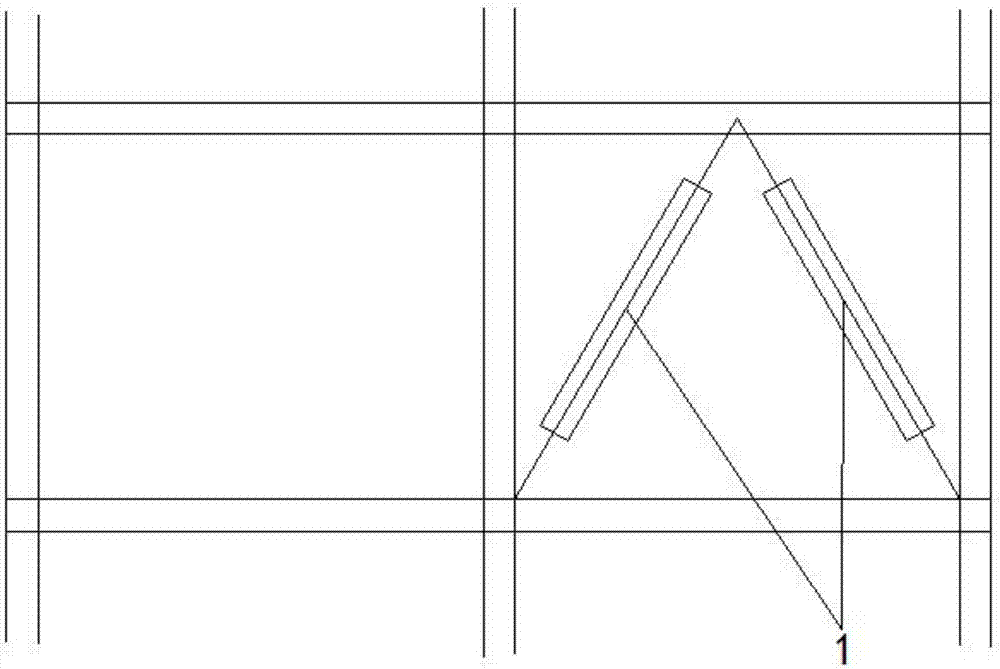

[0059] Such as Figure 4-20 As shown, the X-shaped anti-buckling support structure 2 provided in this embodiment includes a first buckling-resistant support member 21 and a second buckling-resistant support member 22;

[0060] Two of the second anti-buckling support members 22 are respectively fixedly connected to the middle nodes of one of the first anti-buckling support members 21, so that one of the first anti-buckling support members 21 and two of the second anti-buckling support members The buckling support members 22 form an X-shaped arrangement.

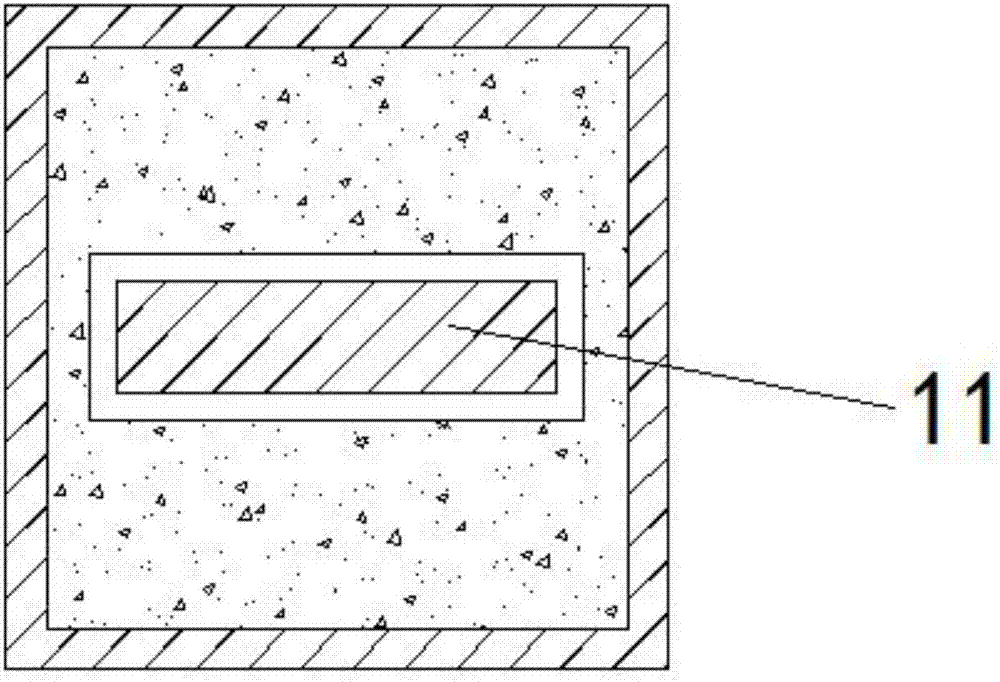

[0061] In an optional implementation manner of the above-mentioned embodiment, such as Figure 5-20 As shown, specifically, as Figure 12-18 As shown, the first anti-buckling support member 21 includes a first support core plate 211, two connecting plates 212, four first stiffeners 213, two second stiffeners 214, four third stiffeners 215 and Four concrete-filled steel tube restraint members 216;

[0062] The two ends of t...

Embodiment 2

[0072] Such as Figure 21 As shown, Embodiment 2 of the present invention provides a frame structure, including the anti-buckling support structure 2 described in any one of the above Embodiment 1.

[0073] The frame structure provided by the second embodiment of the present invention is provided with the anti-buckling support structure 2 provided by the first embodiment, so it has all the beneficial effects of the anti-buckling support structure 2 provided by the first embodiment, and will not be repeated here.

Embodiment 3

[0075] Embodiments of the present invention also provide a connection method for an X-shaped arrangement of buckling-resistant support structures, including;

[0076] Step S1, the first anti-buckling support member 21 includes a first support core plate 211, two connecting plates 212, four first stiffeners 213, two second stiffeners 214, four third stiffeners 215 and Four concrete-filled steel tube restraint members 216;

[0077] The two ends of the first supporting core plate 211 are respectively welded to the two first stiffeners 213, the middle part of the first supporting core plate 211 is welded to the two connecting plates 212, and the two There is a gap between the connecting plates 212;

[0078] Step S2, two second stiffeners 214 are respectively located in the gap, and are respectively welded with the first supporting core plate 211 and the connecting plate 212, using fillet welds;

[0079] Step S3, four third stiffeners 215 are respectively welded on the connecting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com