A kind of forming paper for preparing British flue-cured tobacco type heat-not-burn cigarette core and its preparation method

A heat-not-burn and forming paper technology, which is applied in the field of cigarettes, can solve problems affecting consumer satisfaction, gaps in sensory quality, and insufficient smoke volume, and achieve good application prospects, low cost, and improved smoking quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

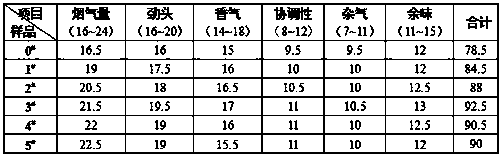

Examples

Embodiment 1

[0053] A preparation method for forming paper for preparing English-style flue-cured tobacco type heat-not-burn cigarette cores, comprising the following steps:

[0054] Step (1), pretreatment: pretreat Burley tobacco stems with microwave expansion until the expansion rate is 200-260%, and then crush and sieve the upper tobacco leaves and the obtained expanded Burley tobacco stems to 70-130% respectively. To obtain tobacco leaf particles and burley expanded tobacco stem particles;

[0055] Step (2), preparation of the first mixture: After mixing the expanded tobacco stem particles and the tobacco leaf particles uniformly at a mass ratio of 6:4, adding a smoking agent therein, stirring until uniformly mixed, and then standing for 1 hour to obtain the first mixture;

[0056] The added mass of the smoke-generating agent is 1 time of the total mass of the Burley tobacco expanded tobacco stem particles and the Burley tobacco leaf particles;

[0057] Described fuming agent is buta...

Embodiment 2

[0077] A preparation method for forming paper for preparing English-style flue-cured tobacco type heat-not-burn cigarette cores, comprising the following steps:

[0078] Step (1), pretreatment: pretreat Burley tobacco stems with microwave expansion until the expansion rate is 200-260%, and then crush and sieve the upper tobacco leaves and the obtained expanded Burley tobacco stems to 70-130% respectively. To obtain tobacco leaf particles and burley expanded tobacco stem particles;

[0079] Step (2), preparation of the first mixture: After mixing the expanded tobacco stem particles and the tobacco leaf particles uniformly according to the mass ratio of 4:6, adding a smoking agent to it, stirring until the mixture is uniform, and then standing for 2 hours to obtain the first mixture;

[0080] The added quality of the smoke-generating agent is twice the total mass of the Burley tobacco expanded tobacco stem particles and the Burley tobacco leaf particles;

[0081] The fuming ag...

Embodiment 3

[0101] A preparation method for forming paper for preparing English-style flue-cured tobacco type heat-not-burn cigarette cores, comprising the following steps:

[0102] Step (1), pretreatment: pretreat Burley tobacco stems with microwave expansion until the expansion rate is 200-260%, and then crush and sieve the upper tobacco leaves and the obtained expanded Burley tobacco stems to 70-130% respectively. To obtain tobacco leaf particles and burley expanded tobacco stem particles;

[0103] Among them, the specific method for performing microwave expansion pretreatment on Burley tobacco stems to an expansion rate of 200-260% is as follows: put Burley tobacco stems with a moisture content of 14-16% into a microwave expansion device, microwave expansion The parameters are frequency 2450MHz, power 900W, and time 20s; the required burley tobacco has expanded stems and no obvious carbonization;

[0104] Step (2), preparation of the first mixture: After mixing the expanded tobacco s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com