Heat-not-burn tobacco flavor formula granules

A technology of heat-not-burn and formulated particles, which is applied in the field of tobacco and can solve problems such as throat irritation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

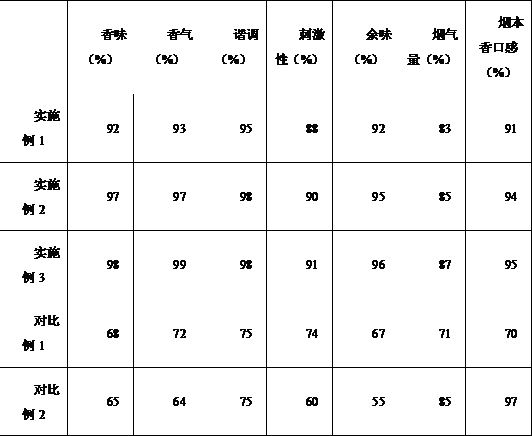

Examples

Embodiment 1

[0041] A method for preparing heat-not-burn tobacco flavor formulation granules, comprising the following steps:

[0042] 1) Take 70 parts by weight of glycerol and 45 parts by weight of menthol into the reaction kettle, adjust the rotation speed to 300rpm and stir, and at the same time, use a water bath to heat until dissolved, the heating temperature is 40°C, and the heating time is 25 minutes to obtain mint brain mixed solution;

[0043] 2) Add 365 parts by weight of tobacco essence and fragrance and 40 parts by weight of peppermint into the reaction kettle, and stir evenly with the menthol mixed solution at room temperature to obtain a tobacco-flavored mixed solution;

[0044] 3) Take 1600 parts by weight of fresh green tea leaves and 1000 parts by weight of fresh Artemisia argyi leaves into the freezer, add dry ice, adjust the temperature to -6°C, heat up to 60°C after freezing for 4 hours, adjust the pressure to 3.0Mpa, last for 30 minutes, and instantly Reduce the pres...

Embodiment 2

[0047] A method for preparing heat-not-burn tobacco original flavor particles, comprising the following steps:

[0048] 1) Take 100 parts by weight of glycerol and 55 parts by weight of menthol into the reaction kettle, adjust the rotation speed to 600rpm and stir, and at the same time, use a water bath to heat until dissolved, the heating temperature is 50°C, and the heating time is 20 minutes to obtain mint brain mixed solution;

[0049] 2) Add 300 parts by weight of tobacco essence and fragrance and 50 parts by weight of peppermint into the reaction kettle, and stir evenly with the menthol mixed solution at room temperature to obtain a tobacco-flavored mixed solution;

[0050] 3) Take 800 parts by weight of fresh green tea leaves and 400 parts by weight of fresh mugwort leaves and put them in the freezer, add dry ice, adjust the temperature to -8°C, heat up to 70°C after freezing for 5 hours, adjust the pressure to 5.0Mpa, last for 30 minutes, and instantly Reduce the pres...

Embodiment 3

[0053] A method for preparing heat-not-burn tobacco flavor formulation granules, comprising the following steps:

[0054] 1) Add 140 parts by weight of glycerol and 60 parts by weight of menthol into the reaction kettle, adjust the rotation speed to 800rpm and stir, while heating in a water bath until dissolved, the heating temperature is 60°C, and the heating time is 15 minutes to obtain mint brain mixed solution;

[0055] 2) Add 240 parts by weight of tobacco essence and fragrance and 85 parts by weight of peppermint into the reaction kettle, and stir evenly with the menthol mixed solution at room temperature to obtain a tobacco-flavored mixed solution;

[0056] 3) Take 600 parts by weight of green tea leaves and 200 parts by weight of Artemisia argyi leaves in a freezer, add dry ice, adjust the temperature to -12°C, freeze for 6 hours and then raise the temperature to 80°C, adjust the pressure to 7.0Mpa, continue for 30 minutes, and drop the pressure instantly To normal pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com