Ceramic flat membrane

A flat membrane and ceramic technology, applied in membrane technology, semi-permeable membrane separation, layered products, etc., can solve the problems of poor ductility, limited service life of ceramic membranes, easy cracking, etc., to improve strength, avoid cleaning dead corners, The effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

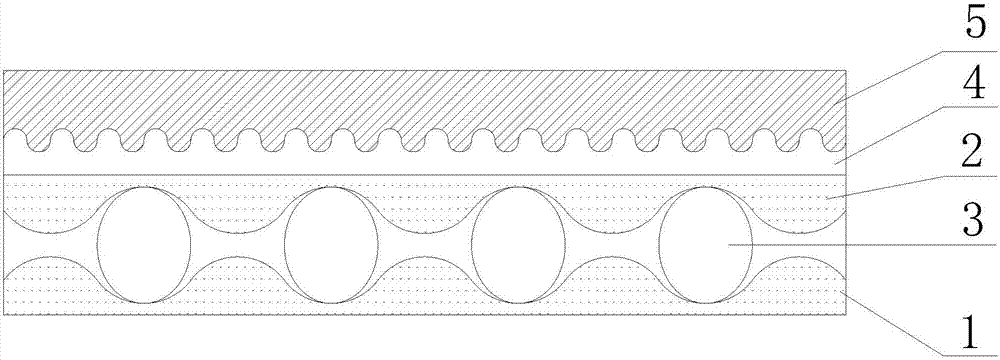

Embodiment 1

[0025] like figure 1 Shown: a ceramic flat membrane of the present embodiment, comprising a membrane layer 5, a transition layer 4 and a porous support layer, wherein the porous support layer comprises a buffer layer 1, a buffer layer 2 and a plurality of support members 3, and the upper layer of the buffer layer 1 Both the surface and the lower surface of the buffer layer 2 are provided with protrusions and depressions, the protrusions and depressions are distributed at intervals and the protrusions and depressions are arc-shaped, and the protrusions of the buffer layer 1 and the protrusions of the buffer layer 2 are opposed to each other. , the depression of the buffer layer 1 and the depression of the buffer layer 2 are opposed one by one, the support member 3 is an ellipsoid whose major axis is in the vertical direction, and whose minor axis is in the horizontal direction, and the upper apex of the ellipsoid touches the bottom of the buffer layer 2 depression , the lower a...

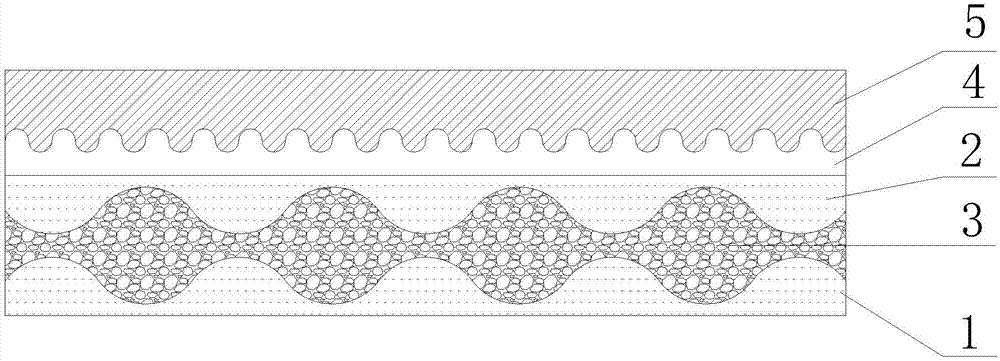

Embodiment 2

[0027] like figure 2 Shown: a kind of ceramic flat membrane of the present embodiment, comprises film layer 5, transition layer 4 and porous support layer, is characterized in that: porous support layer comprises buffer layer 1, buffer layer 2 and support member 3, buffer layer 1 Both the upper surface and the lower surface of the buffer layer 2 are provided with protrusions and depressions, the protrusions and depressions are distributed at intervals and the protrusions and depressions are arc arched, and the support member 3 is arranged between the buffer layer 1 and the buffer layer 2, in order to To enhance its shock resistance, the support member 3 can be filled with fine particles, and the diameter of the fine particles should be much larger than the apertures of the buffer layer 1 and the buffer layer 2. On the one hand, it prevents the fine particles from entering the pores of the buffer layer. On the other hand, It is beneficial to the flow of the liquid. The upper s...

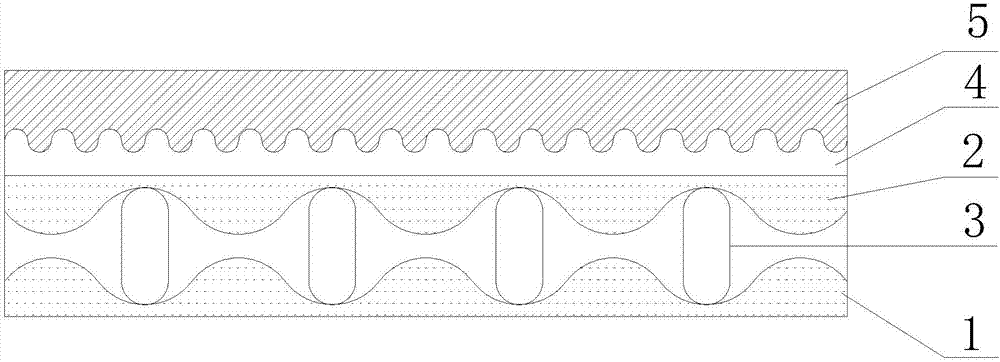

Embodiment 3

[0029] like image 3 Shown: a kind of ceramic flat membrane of the present embodiment, comprises membrane layer 5, transition layer 4 and porous support layer, is characterized in that: porous support layer comprises buffer layer 1, buffer layer 2 and a plurality of supporting parts 3, buffer layer The upper surface of the buffer layer 1 and the lower surface of the buffer layer 2 are provided with protrusions and depressions, the protrusions and depressions are distributed at intervals and the protrusions and depressions are arc arched, and the protrusions of the buffer layer 1 are aligned with the protrusions of the buffer layer 2. Opposed to each other, the depressions of the buffer layer 1 and the depressions of the buffer layer 2 are opposed one by one. The support member 3 is a support column whose upper and lower bottom surfaces are arc-shaped surfaces. The bottom of the buffer layer 1 is depressed, and the upper surface of the buffer layer 2 is provided with a transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com