Steel wire rope cleaning equipment

A technology for cleaning equipment and steel wire ropes, which is applied in the field of steel wire rope cleaning, can solve problems such as steel wire rope safety hazards, achieve good results, high scrubbing efficiency, and solve safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] A kind of steel wire rope cleaning equipment of the present invention will be described in further detail below in conjunction with accompanying drawing and specific embodiment:

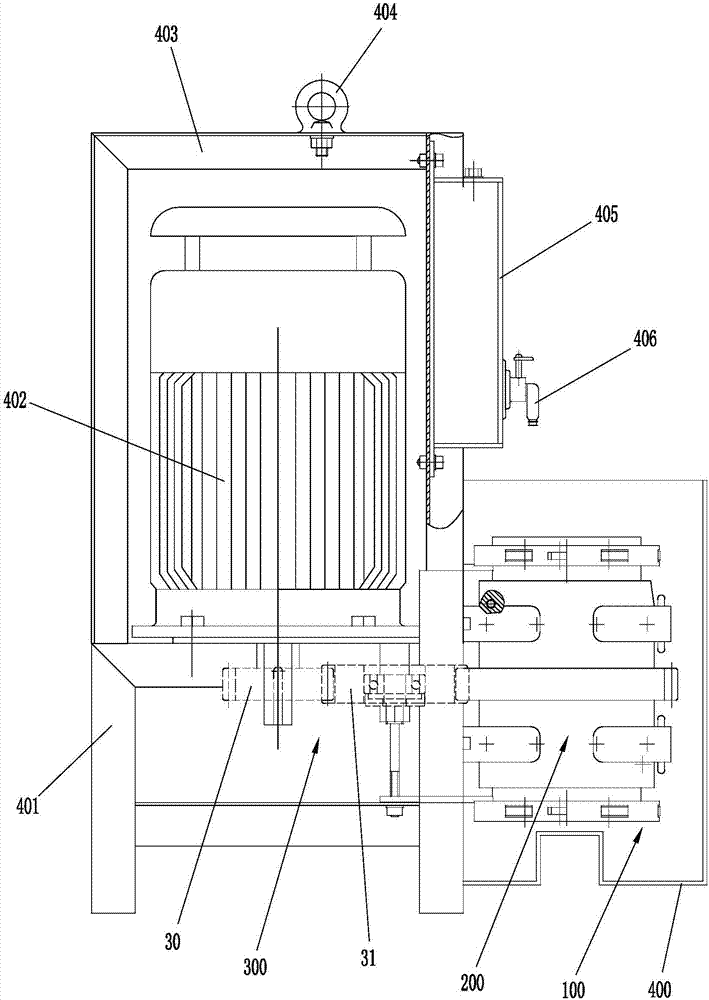

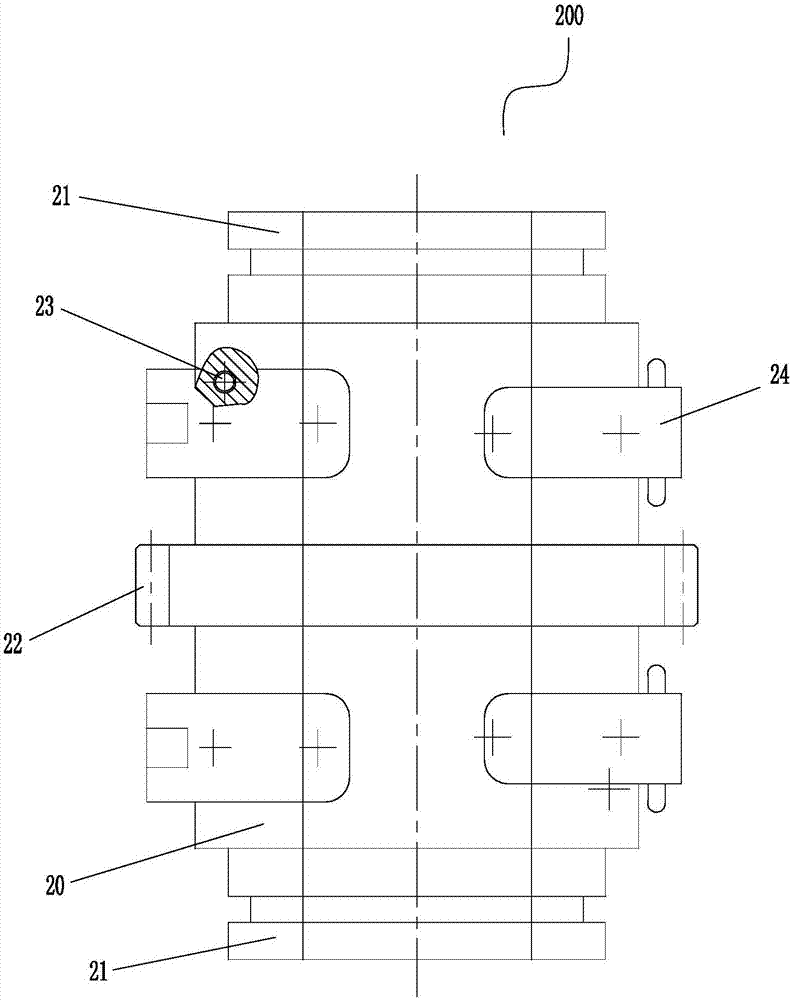

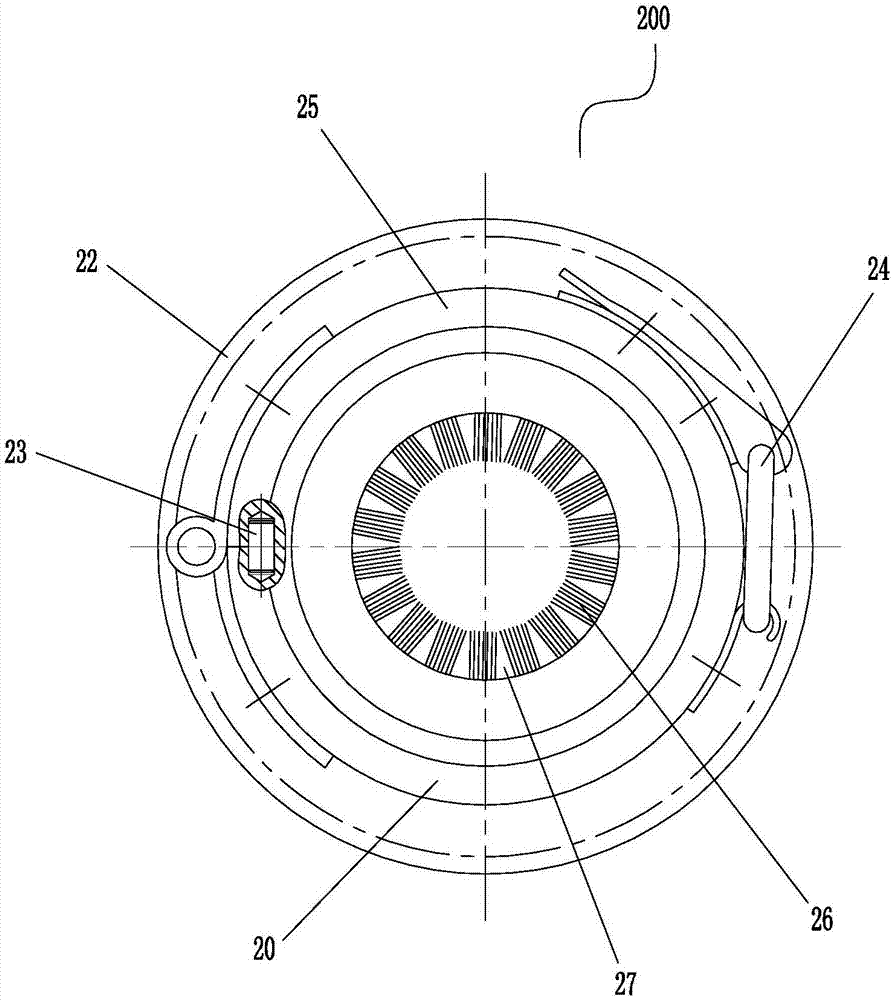

[0030] Such as figure 1 and Figure 6As shown, in this specific embodiment, a wire rope cleaning device of the present invention includes a control unit 50, a first frequency converter 51, a second frequency converter 55, a wireless transmitter 52, a lifting motor 54, a rotating motor 402, and a support base 401 , a liquid storage box 405, a dirt collection box 400 and a cylinder brush 200 for scrubbing the wire rope. The cylinder brush 200 is located in the inner cavity of the dirt collection box 400, and the dirt collection box 400 is a two-half structure, that is, it includes a left half dirt collection box and a right half dirt collection box, and one end of the half dirt collection box and the right half dirt collection box passes through The page is hinged to the support seat 401, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com