A kind of solid rocket motor inner heat insulation layer and forming method thereof

A solid rocket and molding method technology, applied in the field of thermal protection material molding technology, can solve the problems that the molding process is difficult to meet the needs of development, the structure of the thermal insulation layer is complex, etc., and achieves elimination of uneven appearance, good product quality consistency, and application. wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Make the inner insulation layer as follows:

[0043] Step 1: Use a calender to roll the EPDM rubber into a film;

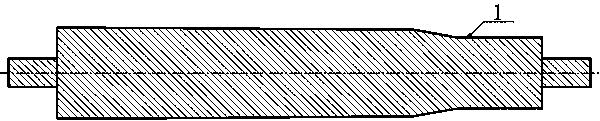

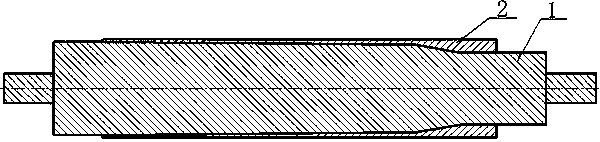

[0044] Step 2: Put figure 1 The mold core 1 shown is fixed on the operating frame, and the film is wrapped layer by layer on the mold core to form a heat insulating sleeve 2 (such as figure 2 shown), wrapped tightly with a fiber braid on the outermost layer.

[0045] Step 3: Put the insulation jacket 2 into a vulcanization tank for curing, the curing temperature is 160°C, the curing time is 60 minutes, and the pressure is normal.

[0046] Step 4: Take out the vulcanized heat insulation jacket 2 and cool to room temperature;

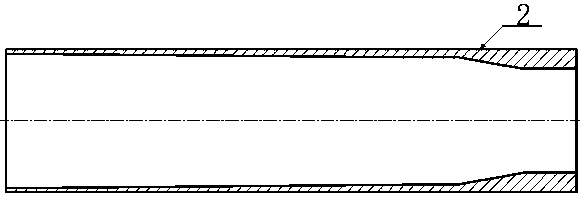

[0047] Step 5: Remove the outer fiber braid, carry out shaping and cutting on the heat insulation sleeve, and take off the heat insulation sleeve from the mold core after shaping; image 3 shown.

[0048] Step 6: Apply adhesive evenly on the outer surface of the heat-insulating sleeve 2, and then paste the heat-insulating sleeve ...

Embodiment 2

[0051] Make the inner insulation layer as follows:

[0052] Step 1: Use a calender to roll the EPDM rubber into a film;

[0053] Step 2: Fix the mold core on the operating frame, wrap the film layer by layer on the mold core to form a thermal insulation sleeve, and wrap the outermost layer with a fiber braid;

[0054] Step 3: Send the insulation sleeve into the vulcanization tank for curing, the curing temperature is 180°C, the curing time is 5 minutes, and the pressure is normal;

[0055] Step 4: Take out the vulcanized heat insulation jacket and cool to room temperature;

[0056] Step 5: Remove the outer fiber braid, reshape and cut the heat insulation sleeve, and take off the heat insulation sleeve from the mold core after shaping;

[0057] Step 6: Apply adhesive evenly on the outer surface of the heat insulation sleeve, and then paste the heat insulation sleeve on the inner wall of the solid rocket motor combustion chamber shell;

[0058] Step 7: Put the combustion cham...

Embodiment 3

[0060] Make the inner insulation layer as follows:

[0061] Step 1: Use a calender to roll the EPDM rubber into a film;

[0062] Step 2: Fix the mold core on the operating frame, wrap the film layer by layer on the mold core to form a thermal insulation sleeve, and wrap the outermost layer with a fiber braid;

[0063] Step 3: Send the heat insulating sleeve into the vulcanization tank for curing, the curing temperature is 120°C, the curing time is 120min, and the pressure is normal;

[0064] Step 4: Take out the vulcanized heat insulation jacket and cool to room temperature;

[0065] Step 5: Remove the outer fiber braid, reshape and cut the heat insulation sleeve, and take off the heat insulation sleeve from the mold core after shaping;

[0066] Step 6: Apply adhesive evenly on the outer surface of the heat insulation sleeve, and then paste the heat insulation sleeve on the inner wall of the solid rocket motor combustion chamber shell;

[0067] Step 7: Put the combustion cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com