Constructed wetland renewable matrix block structure, and making and using method thereof

A technology of constructed wetlands and matrix blocks, applied in sustainable biological treatment, chemical instruments and methods, biological treatment devices, etc., can solve problems affecting the normal operation of the system, long replacement period of matrix, non-renewability, etc., and achieve low manufacturing cost , strong operability, and simple equipment and technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] Example 1: Park Constructed Wetland

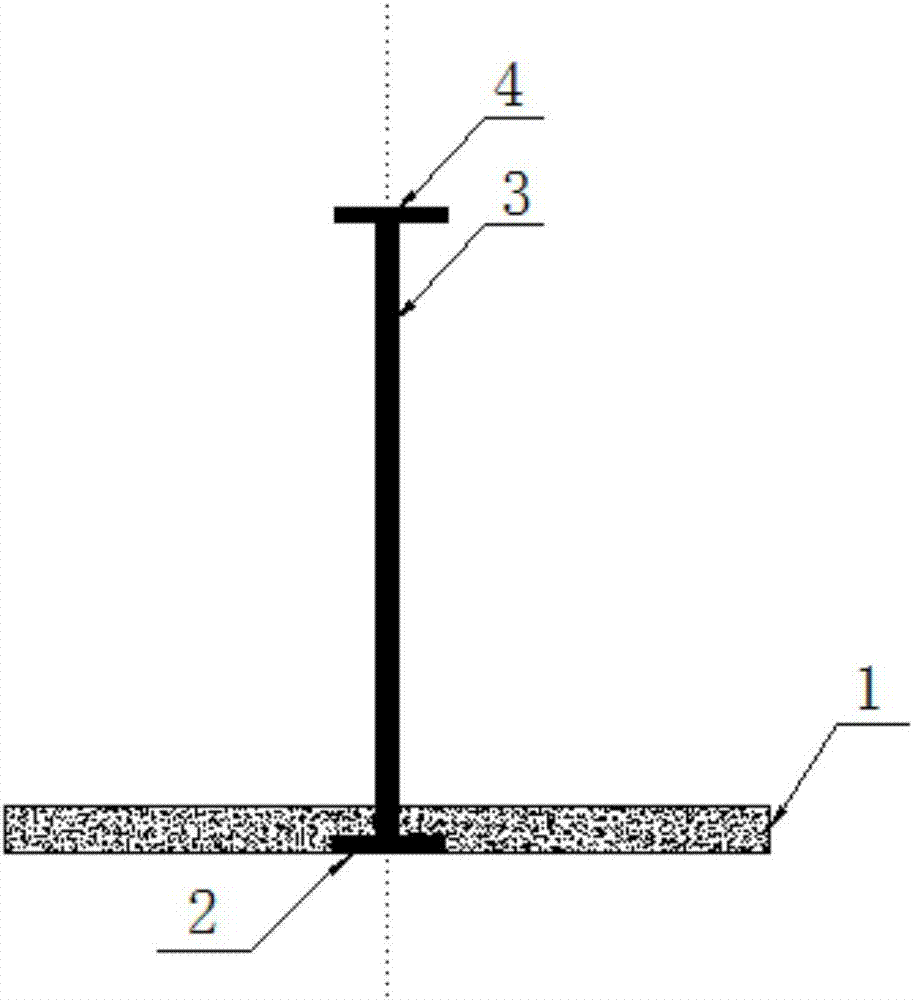

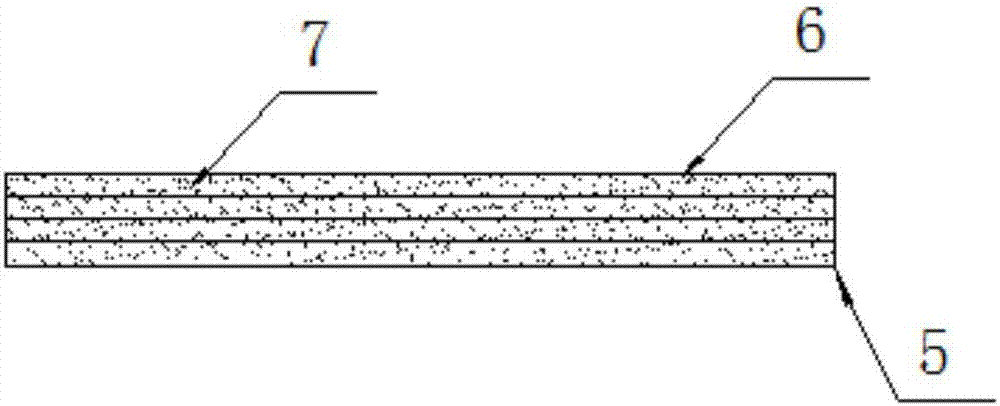

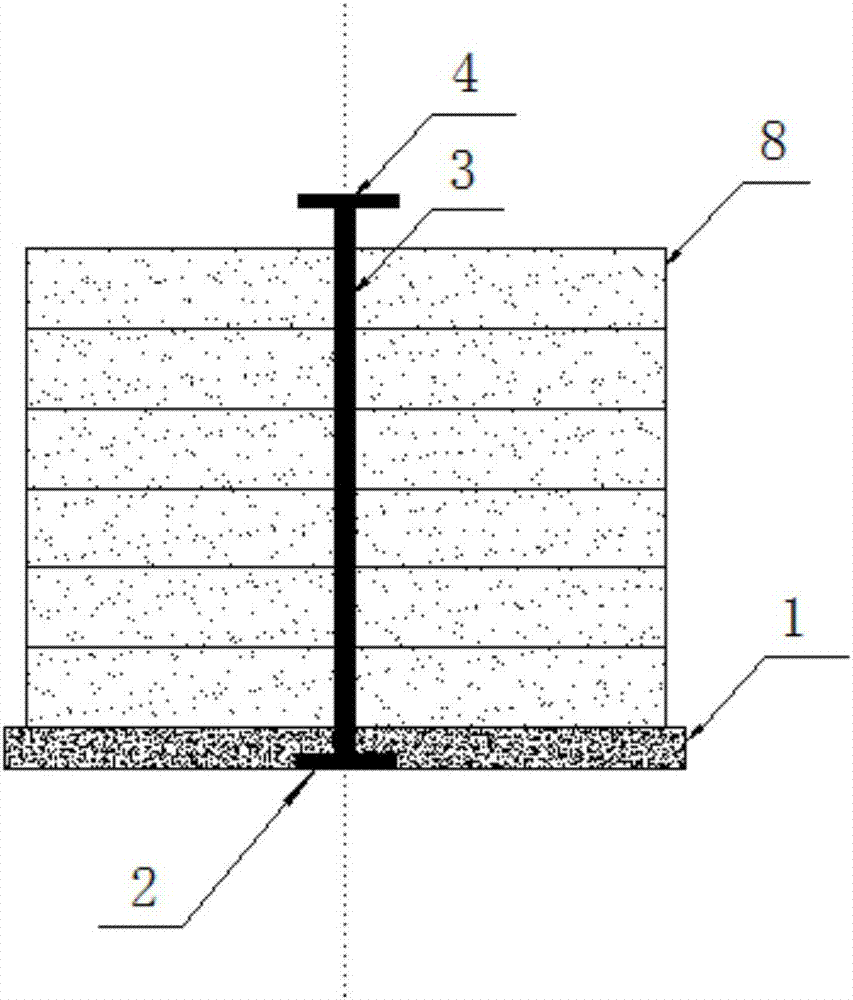

[0022] Such as figure 1 , figure 2 and image 3 As shown, the constructed wetland renewable matrix block structure includes two parts: the matrix block fixing component and the matrix block. The constructed wetland matrix block fixing component includes a bottom plate 1, a fixed end 2, an upper lifting rod 3 and an upper lifting head 4. The matrix block 8 consists of Composed of two matrix sheets 5, the matrix sheet 5 is composed of a poplar cotton layer 6 and a matrix 7, and the matrix block 8 is compressed and fixed on the matrix block fixing member.

[0023] Bottom plate 1 is made of concrete permeable board with a width of 350 mm, a length of 500 mm, and a thickness of 20 mm; the upper lifting rod 3 is made of plastic with a diameter of 10 mm; upper lifting head 4 is made of wood, with a length of 50 mm, a width of 20 It is 10mm, fixed on the lifting rod 3.

[0024] After the matrix block 8 is manufactured, it is compressed...

example 2

[0029] Example 2: Courtyard Constructed Wetland

[0030] Such as figure 1 , figure 2 and image 3 As shown, the artificial wetland renewable matrix block structure is prepared for courtyard-style artificial wetlands. The bottom plate 1 is made of concrete permeable board with a width of 200mm, a length of 300mm, and a thickness of 10mm; the lifting rod 3 is made of plastic and has a diameter of 5mm; The upper lifting head 4 is made of plastic, with a length of 30 mm, a width of 10 mm, and a thickness of 5 mm, and is fixed on the upper lifting rod 3 .

[0031] After the matrix block 8 is made, it is compressed with a pressure of 50kPa. After compression, the center is opened, and the hole diameter is larger than the diameter of the lifting rod 3 by 2mm. The length and width of the prepared matrix block 8 are smaller than the bottom plate by 2mm.

[0032] Poplar wadding layer 6 is woven from poplar wadding with a layer thickness of 1 mm. The matrix sheet 5 is composed of 3 l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com