Oily sludge treatment process and treatment system

A sludge treatment and process technology, applied in the direction of sludge treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of environmental secondary pollution damage, environmental damage, large amount and cannot be stored in large quantities, etc. To achieve the effect of zero pollution discharge and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0052] For the convenience of description, words such as primary and secondary are used in the present invention to describe different materials obtained in different processes, which do not constitute a limitation to the present invention.

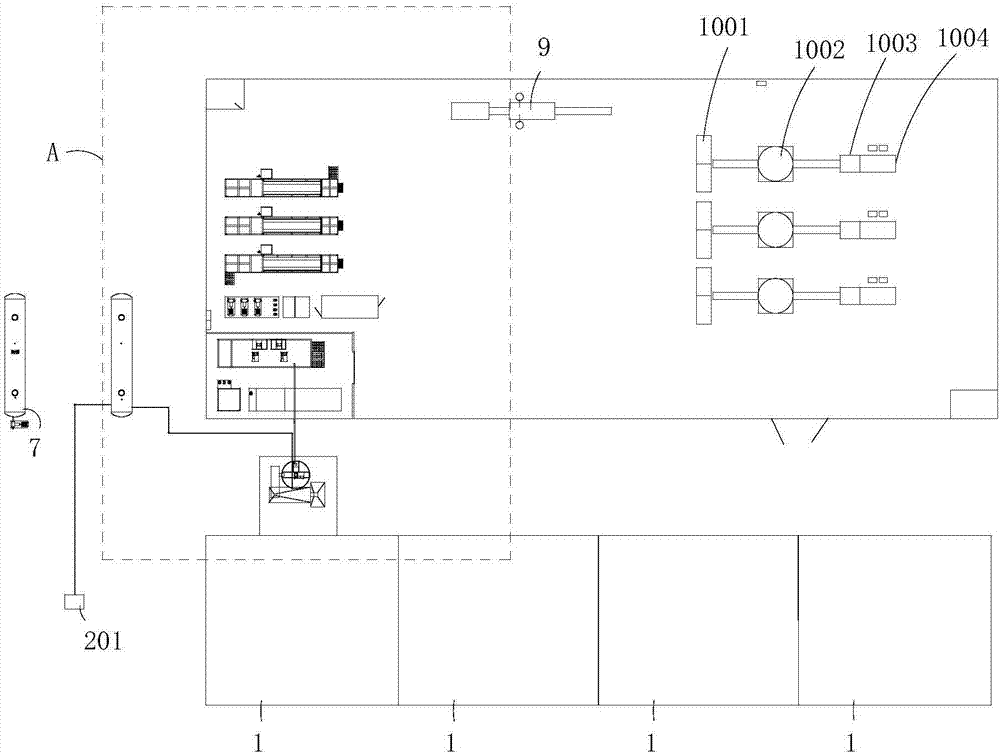

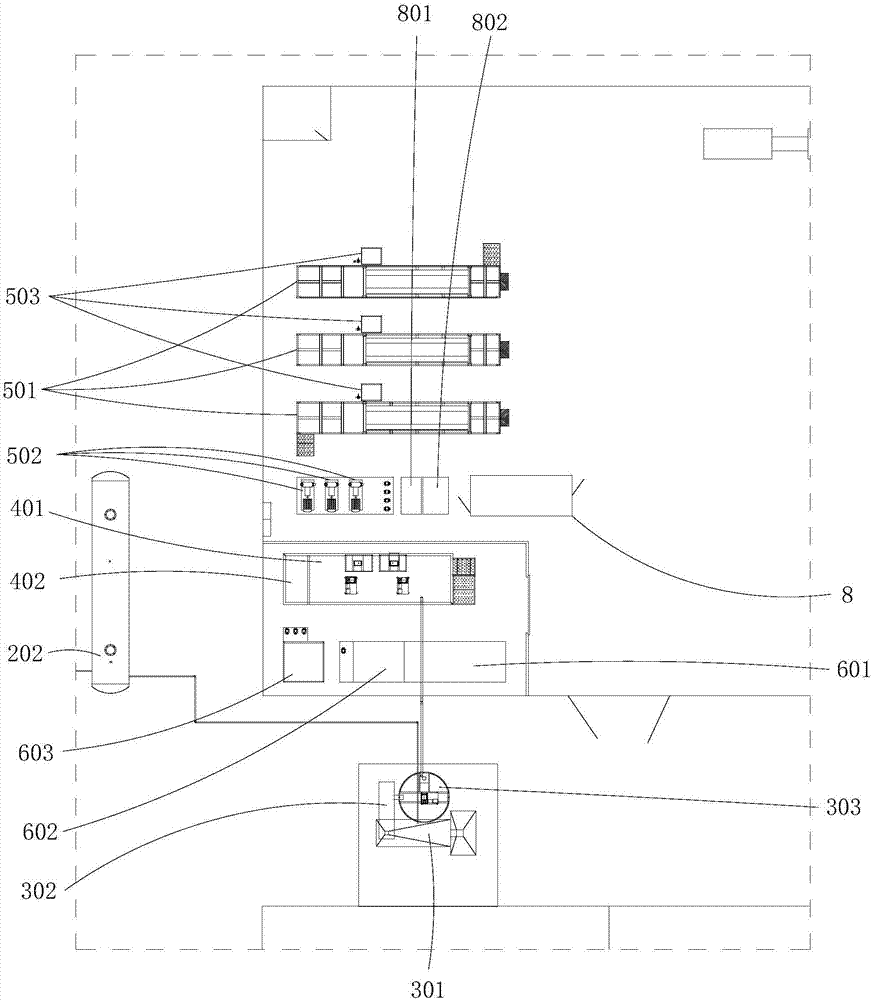

[0053] The present invention will be described in detail below with reference to the accompanying drawings and examples.

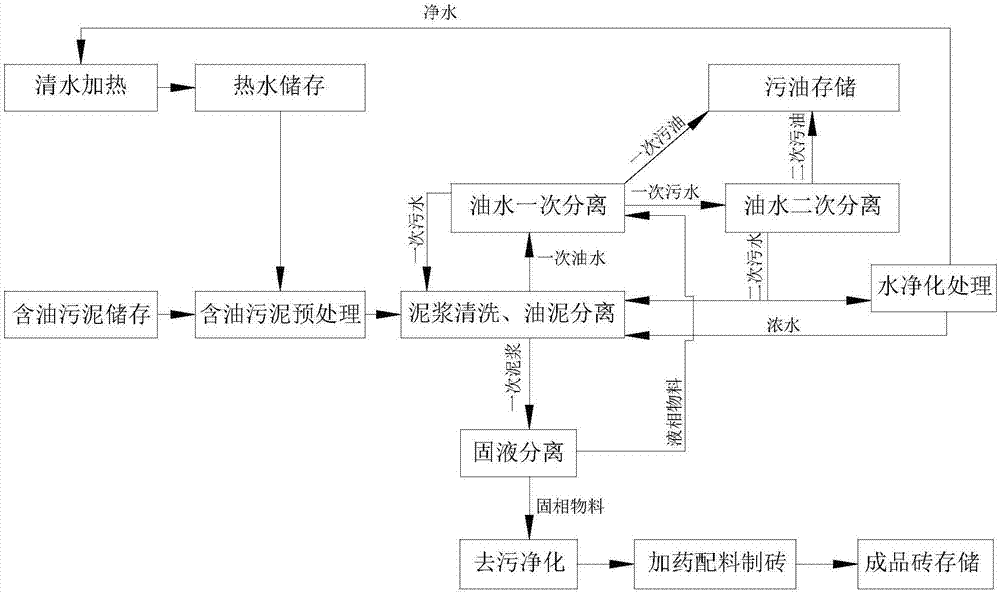

[0054] This embodiment relates to a process for treating oily sludge, combining figure 1 shown, including the following steps:

[0055] a1. Oily sludge storage, transporting the oily sludge into the site for storage; the oily sludge in this process includes the oily sludge cleaned from the crude oil storage tank, and the oily sludge produced during the oil well testing process, which can be Transported into the site by tank truck to be processed. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com