Anticorrosion S-shaped pipeline

An anti-corrosion and pipeline technology, used in pipeline protection, anti-corrosion coatings, pipeline anti-corrosion/anti-rust protection, etc., can solve the problems of easy scaling and corrosion of oil pipelines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

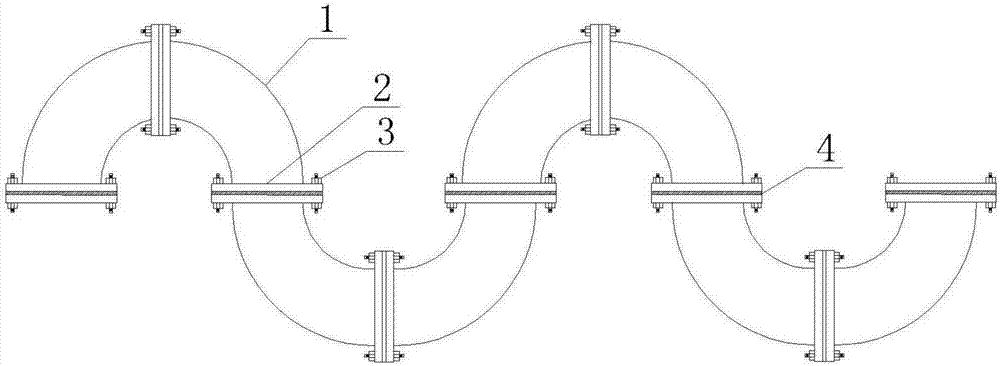

[0023] Such as figure 1 As shown, this embodiment provides an anti-corrosion S-shaped pipeline, which includes a plurality of hollow pipes connected in sequence, and each pipe includes a bending part 1 and a fixing part 2 arranged at the openings at both ends of the bending part 1 , the bending portion 1 is a 1 / 4 arc, the fixing portions 2 between adjacent bending portions 1 are fixedly connected by bolts 3 , and a sealing portion 4 is provided between the fixing portions 2 . Each bending part 1 is connected end to end to form a sine wave shape.

[0024] In this embodiment, the fixing part 2 is a flange, and in order to increase the corrosion resistance of the pipeline, an anti-corrosion layer is provided on the inner wall of the pipe fitting. This new type of implementation is set at the front end of the oil pipeline to precipitate barium strontium scale. When the medium passes through the pipeline, it goes through a cycle process of rising-falling-rising-falling-rising. The...

Embodiment 2

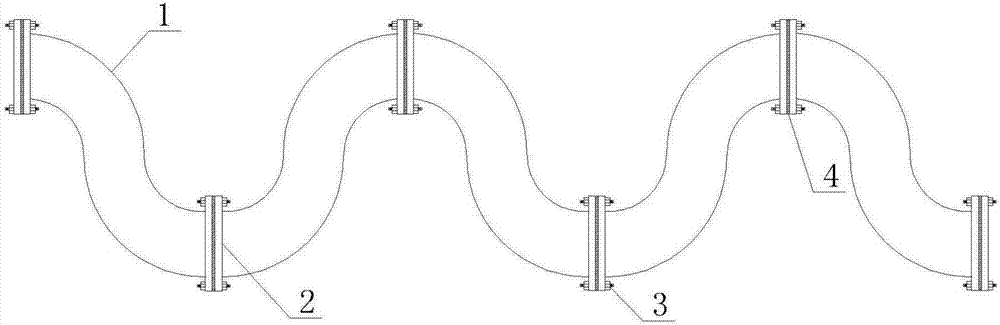

[0033] Such as figure 2 As shown, this embodiment provides an anti-corrosion S-shaped pipeline, which includes a plurality of hollow pipes connected in sequence, and each pipe includes a bending part 1 and a fixing part 2 arranged at the openings at both ends of the bending part 1 , the bending portion 1 is S-shaped, the fixing portions 2 between adjacent bending portions 1 are fixedly connected by bolts 3 , and the sealing portion 4 is provided between the fixing portions 2 . Each S-shaped bending part 1 is connected end to end to form a sine wave shape.

[0034] In this embodiment, the fixing part 2 is a flange, and in order to increase the corrosion resistance of the pipeline, an anti-corrosion layer is provided on the inner wall of the pipe fitting. This new type of implementation is set at the front end of the oil pipeline to precipitate barium strontium scale. When the medium passes through the pipeline, it goes through a cycle process of descending-rising-falling-risi...

Embodiment 3

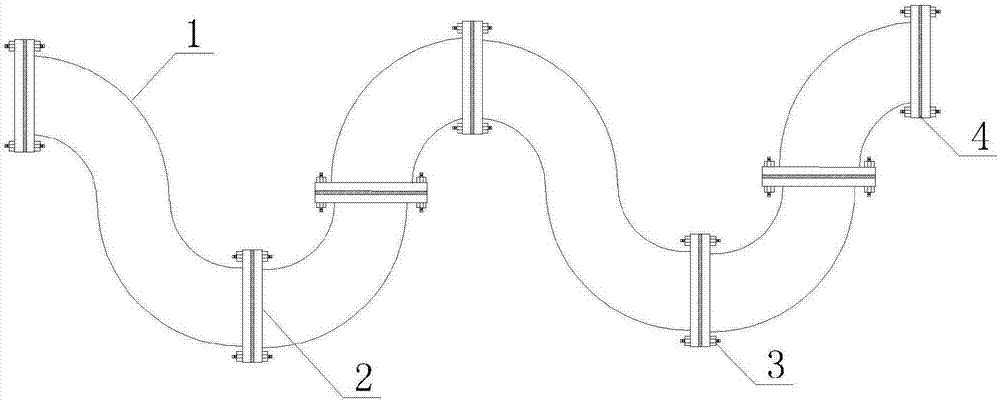

[0043] Such as image 3As shown, this embodiment provides an anti-corrosion S-shaped pipeline, which includes a plurality of hollow pipes connected in sequence, and each pipe includes a bending part 1 and a fixing part 2 arranged at the openings at both ends of the bending part 1 , the bending part 1 is 1 / 4 arc or S-shaped, the fixing parts 2 between adjacent bending parts 1 are fixedly connected by bolts 3 , and the sealing part 4 is arranged between the fixing parts 2 . Each bending part 1 is connected end to end to form a sine wave shape.

[0044] In this embodiment, the fixing part 2 is a flange, and in order to increase the corrosion resistance of the pipeline, an anti-corrosion layer is provided on the inner wall of the pipe fitting. This new type of implementation is set at the front end of the oil pipeline to precipitate barium strontium scale. When the medium passes through the pipeline, it goes through a cycle of descending-rising-decreasing-rising. The barium-stron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com