Turbo-type high-frequency pulse pressurizer

A high-frequency pulse, turbine-type technology, used in drilling with liquid/gas jets, etc., can solve the problems of short drill life, low drilling efficiency, and high cost, and achieve the effect of reducing drilling cost and increasing rock breaking efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

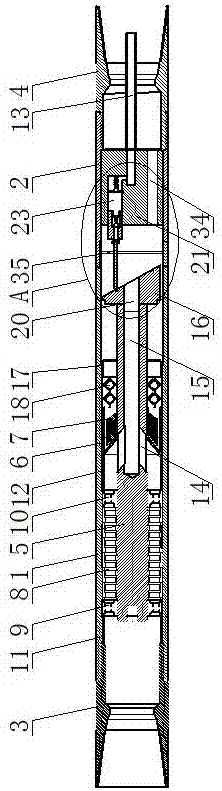

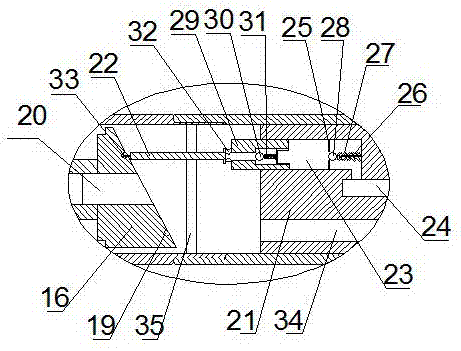

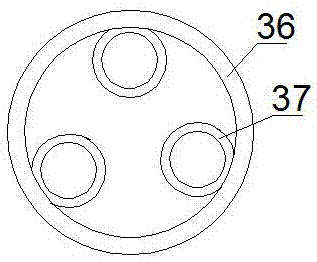

[0024] The turbo-type high-frequency pulse supercharger is composed of a housing 1 , a connecting sleeve 2 , an upper joint 3 , a lower joint 4 , a turbine shaft 5 , a restrictor sleeve 6 and a shunt sleeve 7 . One end of the shell 1 is threaded with an upper joint 3, the other end of the shell 1 is threaded with a connecting sleeve 2, and the end of the connecting sleeve 2 is threaded with a lower joint 4; the center hole of the lower joint 4 is provided with a high-pressure flow pipe 13. The high-pressure runner pipe 13 communicates with the nozzle on the drill bit through a communication pipe. A turbine shaft 5 is installed in the housing 1 via a turbine 8 . The turbine 8 is composed of a turbine stator and a turbine rotor. The turbine stator and the turbine rotor are respectively connected and fixed with the housing 1 and the turbine shaft 5 through overfitting. The upper centering bearing 9 is installed on the turbine shaft 5 on one side of the turbine 8; the upper cente...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com