Method and device for measuring fluid-solid coupling parameters of a plurality of spent fuel storage grids

A storage grid and fluid-solid coupling technology, applied in the field of measurement of fluid-solid coupling parameters, can solve problems such as difficult operation, large measurement error, and low measurement accuracy, and achieve convenient and accurate adjustment, true measurement results, and increased work safety Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

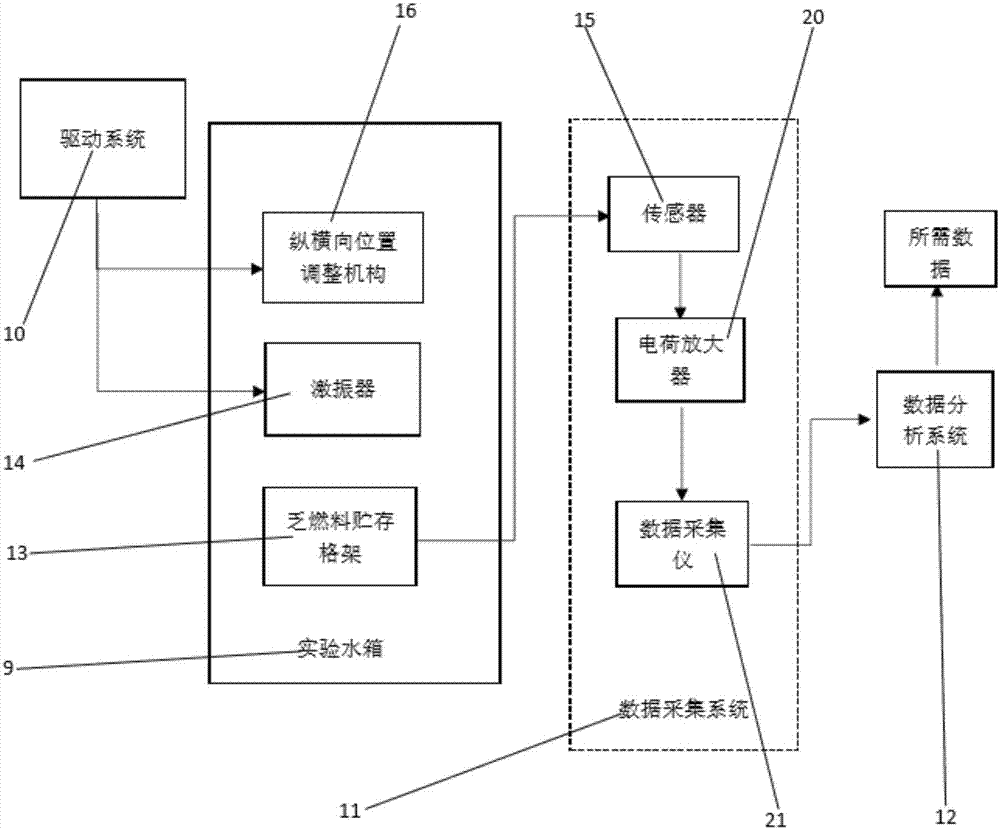

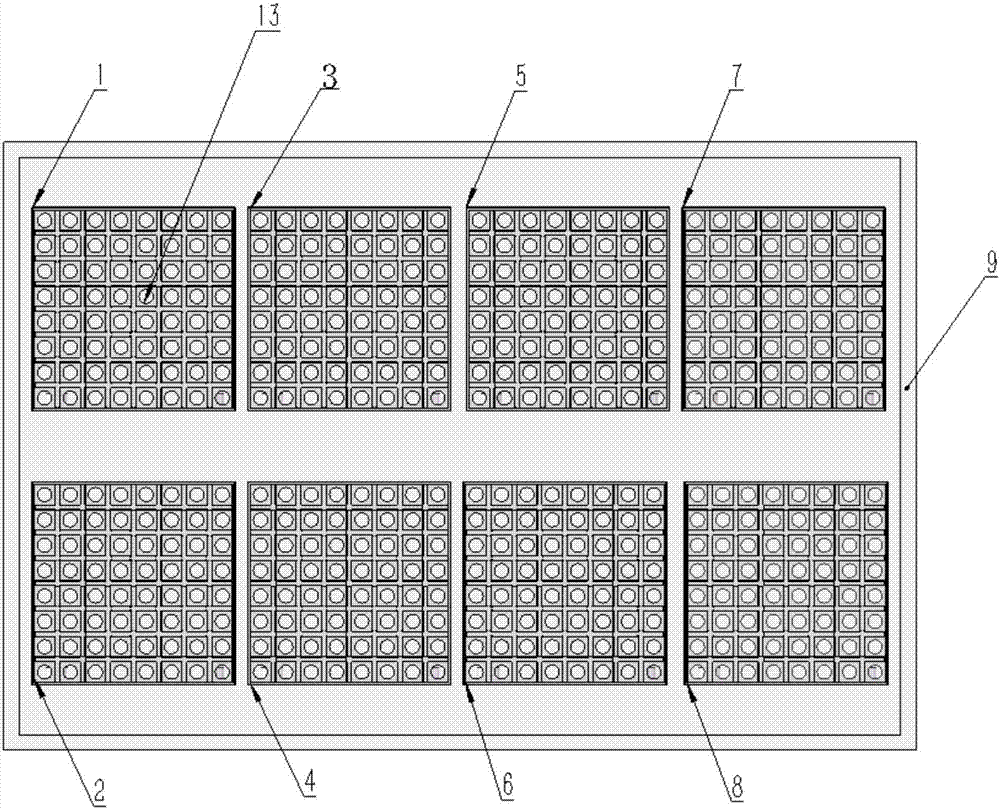

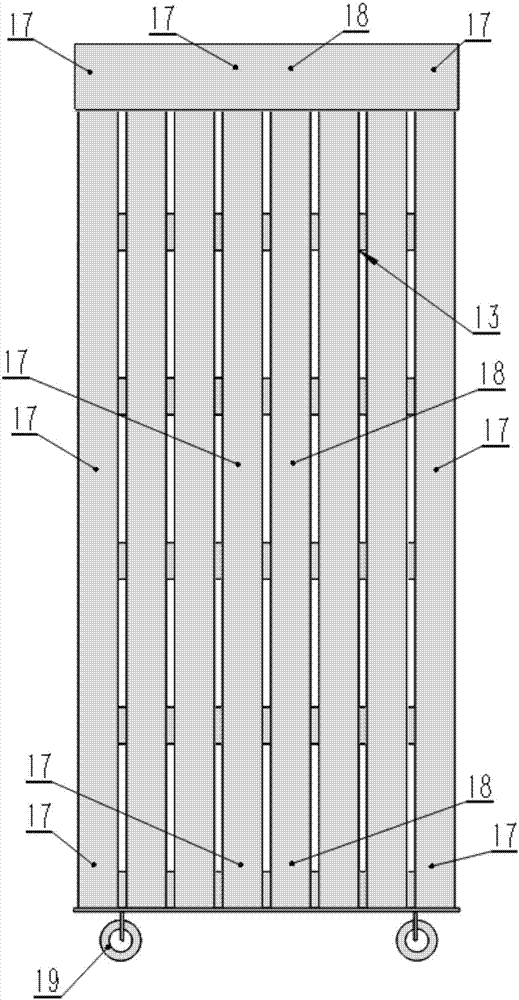

[0031] A schematic diagram of a method and device for measuring fluid-solid coupling parameters of multiple spent fuel storage grids described in this embodiment, a diagram of the arrangement of measurements, and a schematic diagram of the structure of the measurement device are shown in Figure 1 to Figure 5 shown.

[0032] Plate structures are very common in reactor structural engineering. A major feature of the plate-like structure working in the reactor is that there is a strong fluid-solid coupling between the fluid and the solid. At present, there are few studies on the vibration characteristics of the fluid-structure interaction of the plate-like structure in the reactor engineering structure. In engineering, in order to simplify the calculation of the additional mass of the fluid-solid coupling of the plate structure, the flat plate is generally used to directly replace the orifice plate for calculation. There is a large error between the calculation results obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com