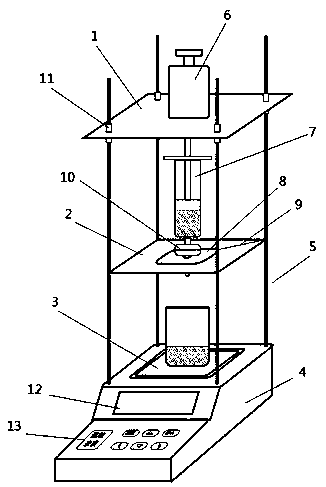

A semi-automatic detection device for the filtration value of spinning solution

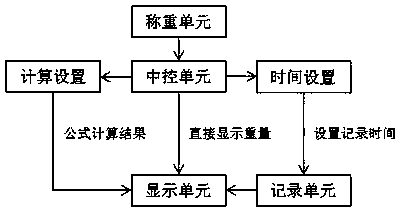

A detection device and a technology for filtering values, which are applied in measurement devices, material weighing, instruments, etc., can solve the problems of cumbersome determination of filtering values and lack of visual means, and are beneficial to inspection efficiency, accuracy improvement, and product stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

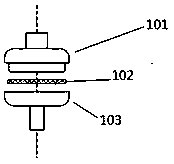

[0020] First, add 100 grams of spinning solution into the sample delivery barrel, and put a 250-mesh circular filter cloth into the filter. After installation, the glue outlet of the filter is placed in the small hole of the sample table, the glue outlet passes through the small hole, and the upper part of the sample delivery barrel is fitted with the pressure table to ensure that the sample delivery barrel is vertically fixed. Set the control base, the first recording time is 60 seconds, and the second recording time is 300 seconds. After zeroing, place the weight on the pressure table. The weight of the weight pushes the push rod in the sample feeding barrel to release the spinning hydraulic pressure. The filter element in the filter will filter the impurities in the spinning solution. Since the impurities in the spinning solution are continuously accumulated on the filter cloth, its filtration resistance increases with the increase of the filtration time. When the resistan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com