A kind of film layer structure, display device and preparation method of film layer structure

A technology of film layer structure and laminated structure, which is applied in semiconductor/solid-state device manufacturing, organic semiconductor devices, semiconductor devices, etc., can solve problems such as affecting the life of OLED devices and being prone to cracking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

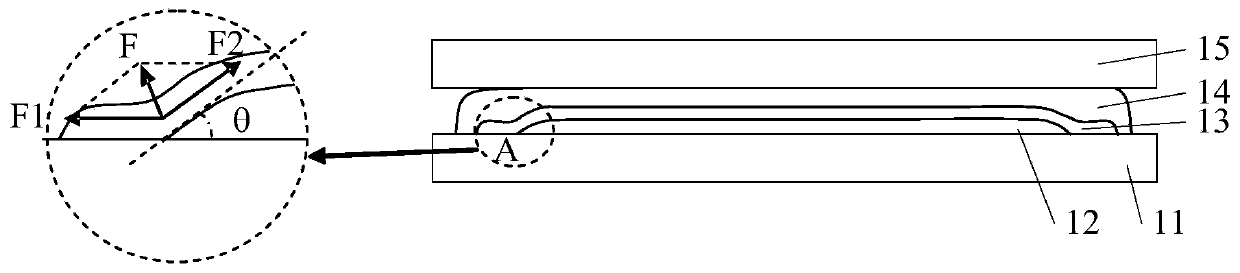

[0036] refer to figure 1 , showing one of the schematic diagrams of the film layer structure in the embodiment of the present invention.

[0037] An embodiment of the present invention provides a film layer structure, which is applied to an electroluminescent display panel. The electroluminescent display panel includes a substrate, and a first organic film layer 12 is disposed on the substrate 11; the first organic film Layer 12 is an organic film layer whose outer edge is closest to the edge of the substrate 11 in the film layer structure, and the climbing angle between the first organic film layer 12 and the substrate 11 is smaller than the breakable angle.

[0038] In the embodiment of the present invention, the substrate 11 may be a rigid substrate or a flexible substrate.

[0039] like figure 1 As shown, the schematic diagram on the left is a partial enlarged view of region A (the position of the dotted circle) in the film layer structure, the climbing angle between the...

Embodiment 2

[0064] An embodiment of the present invention also provides a display device, which includes the above-mentioned film layer structure, and the film layer structure is applied to an electroluminescent display panel, and the electroluminescent display panel includes a substrate, and the substrate is provided with the first organic film layer;

[0065] The first organic film layer is the organic film layer whose outer edge of the film layer is closest to the edge of the substrate in the film layer structure, and the climbing angle between the first organic film layer and the substrate is smaller than the breakable angle

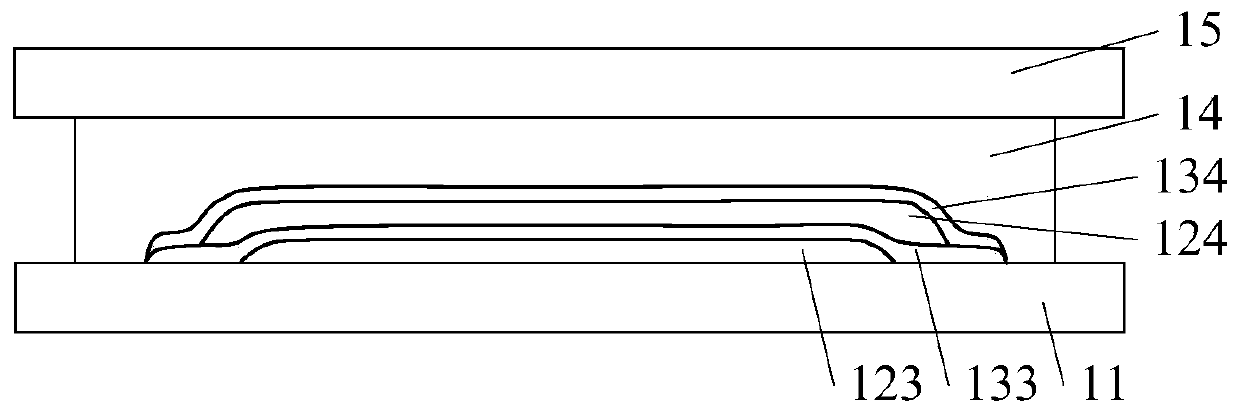

[0066] Wherein, the breakable angle is 35°; the first organic film layer is the organic film layer in the backplane structure or the organic film layer in the packaging structure; the first organic film layer is also provided with a first inorganic film layer.

[0067] In one embodiment of the present invention, the first organic film layer is an organic film l...

Embodiment 3

[0073] refer to Figure 4 , shows a flow chart of a method for preparing a film layer structure in an embodiment of the present invention.

[0074] Step 401, forming a first organic film layer on a substrate.

[0075] In the embodiment of the present invention, firstly, the first organic film layer is formed on the substrate. Since the types of the first organic film layer are different, their preparation methods are also different.

[0076] Wherein, the first organic film layer is the organic film layer whose outer edge of the film layer is closest to the edge of the substrate in the film layer structure, and the climbing angle between the first organic film layer and the substrate is smaller than angle.

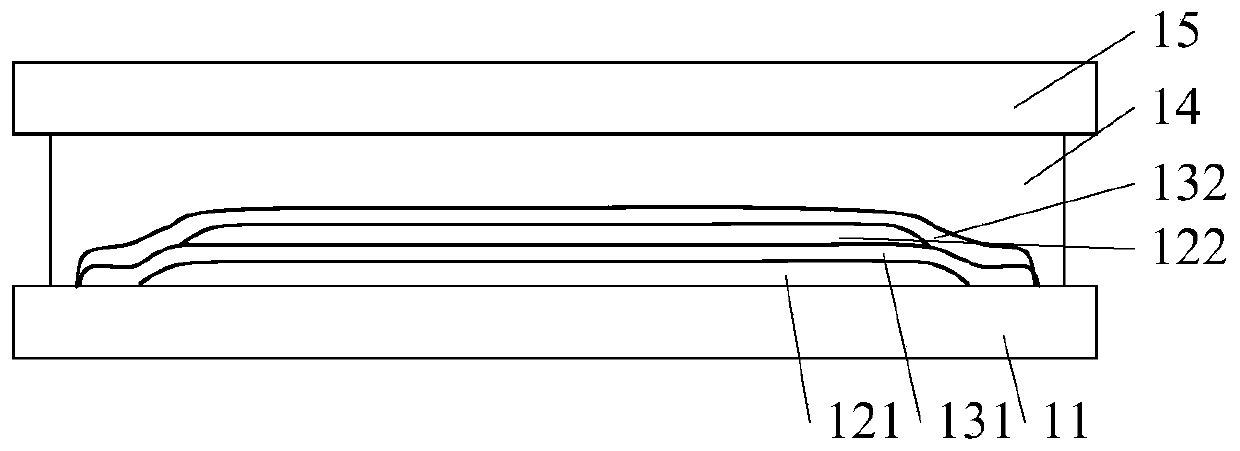

[0077] refer to figure 2 , when the first organic film layer 121 is an organic film layer in the backplane structure, the first organic film layer 121 is formed by exposure and development processes, by adjusting the exposure intensity, exposure time, developer concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com