Hot-rolled strip steel mathematical model data layer judgment method

A mathematical model and hot-rolled strip technology, applied in metal rolling, metal rolling, rolling mill control devices, etc., can solve the problem of reducing model calculation accuracy, unavoidable cross-layer phenomena, and affecting product dimensional accuracy and rolling stability To achieve the effect of improving setting accuracy and rolling stability, ensuring setting reliability and maintaining continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] A kind of method for judging the data layer of hot-rolled strip mathematical model data according to the present invention is characterized in that, comprising:

[0039] 1) Mathematical model layer division rules:

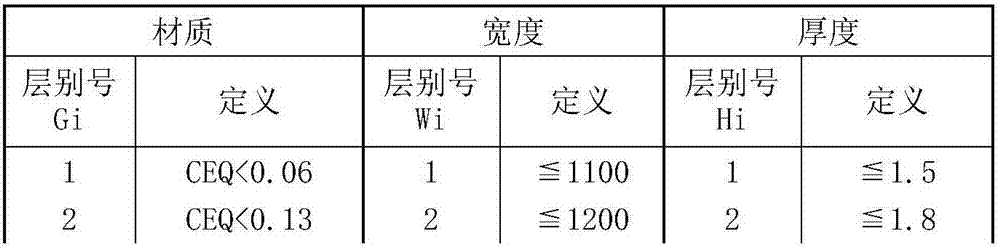

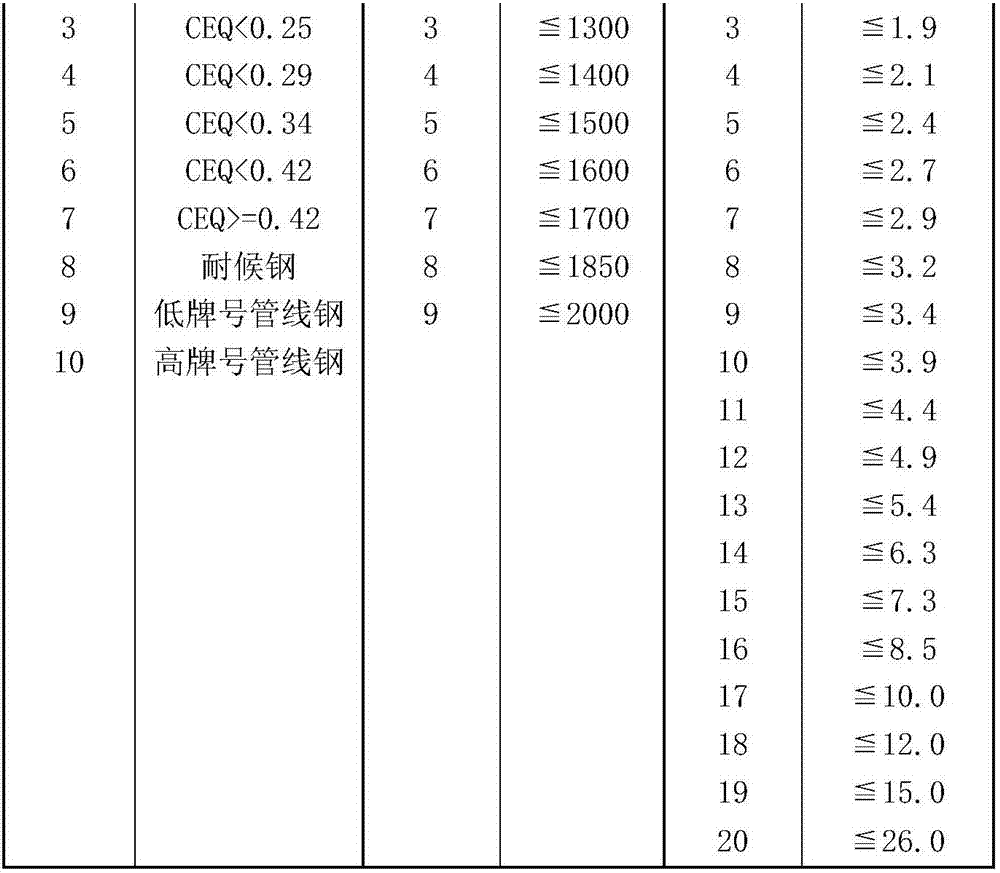

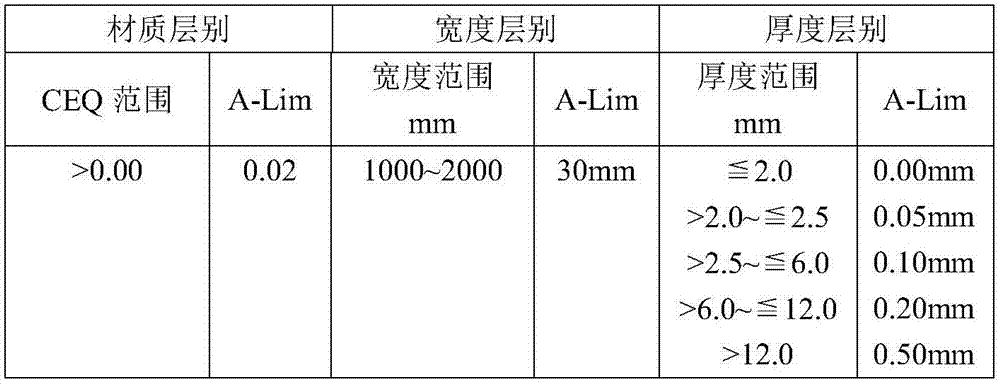

[0040] The main factors affecting the rolling stability of the strip steel or the properties of the strip steel are: steel type, thickness, width, finishing temperature and coiling temperature. The rules for dividing the layers of the mathematical model according to different factors affecting the properties of the strip steel are:

[0041] a) Classification of material layers: For varieties with no sudden change in strip properties, the material layers are classified according to carbon equivalent CEQ, and the layer number of each file is Gi, i=1~10; the carbon equivalent interval LGi of each file is 0.03 ~0.10; CEQ calculation formula is:

[0042] CEQ=(C+Mn / 6+Si / 24)×100%; wherein C, Mn, Si are respectively the weights of carbon, manganese, and silicon ele...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com