Automatic machining system for experiment table surface water blocking groove

A technology of automatic processing and waterproof groove, which is applied in the direction of metal processing equipment, manufacturing tools, milling machine equipment details, etc., can solve problems such as inability to machine processing, and achieve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below, the technical solution of the present invention will be described in detail through specific examples.

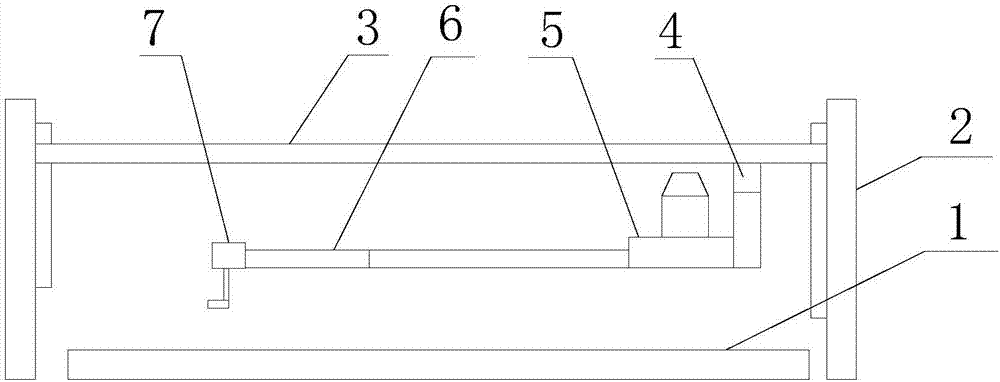

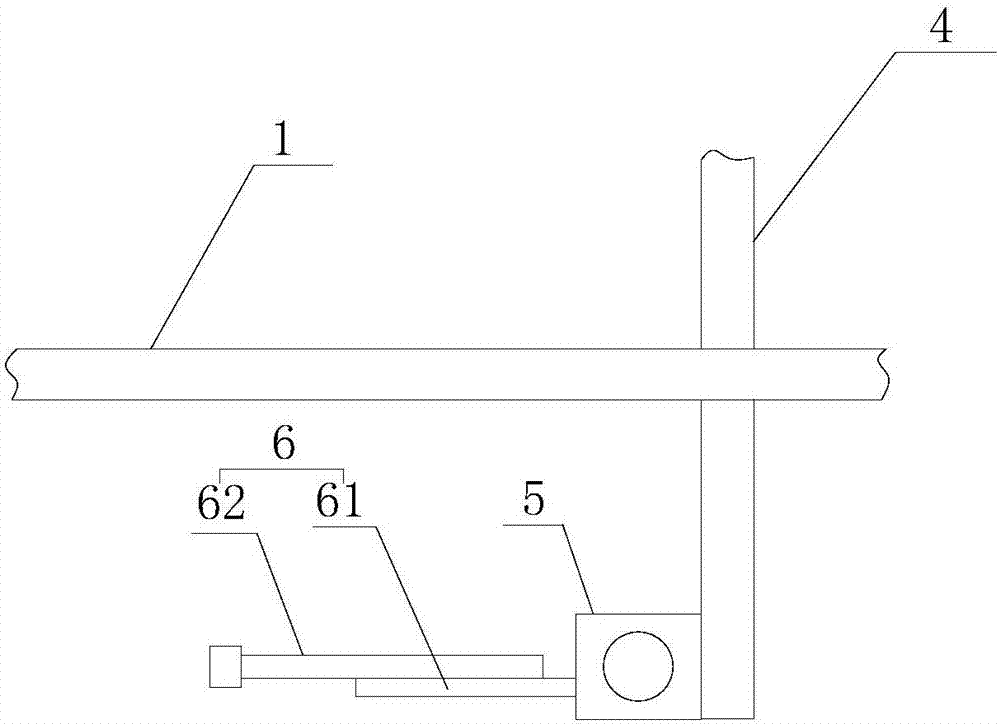

[0030] Such as Figure 1-2 as shown, figure 1 It is a structural schematic diagram of an automatic processing system for a test table waterproof groove proposed by the present invention; figure 2 It is a schematic diagram of the assembly of the first guide rail and the second guide rail in the automatic processing system for the waterproof groove of the experimental table proposed by the present invention.

[0031] refer to Figure 1-2 , an automatic processing system for an experimental table top waterproof groove proposed by an embodiment of the present invention, comprising: a workbench 1, a support frame 2, a first guide rail 3, a second guide rail 4, a carriage 5, a movable rod 6, a groove milling mechanism 7, The first drive mechanism, the second drive mechanism, the third drive mechanism, the fourth drive mechanism and the first sensor, the second s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com