Animal fat and extraction method thereof

A technology of animal fat and extraction method, which is applied in the direction of fat oil/fat production, fat production, etc., can solve the problems of deterioration of animal fat taste, decreased nutritional value, change of color and physical properties, etc., and achieves enhanced flavor, sensory flavor, nutrition High value, good color results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

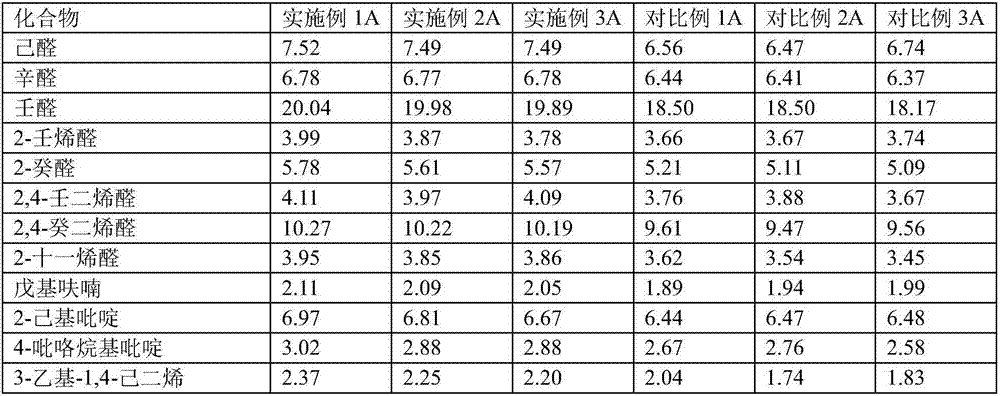

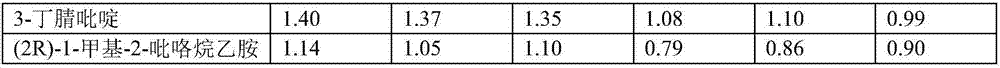

Examples

Embodiment 1A

[0033] A method for extracting animal fat, comprising the steps of:

[0034] (1) Under the condition that the rotating speed is 20 rpm, put 100Kg of pig adipose tissue into the reactor, heat up to 55°C, and keep the temperature for 3.5 hours;

[0035] (2) Under the condition that the rotating speed is 25 rpm, the temperature is raised to 80° C., and the temperature is kept for 2 hours;

[0036] (3) Under the condition that the rotating speed is 30 rpm, add 10Kg of pork enzymatic hydrolysis powder, heat up to 100°C, and keep warm for 2 hours;

[0037] (4) Under the condition that the rotating speed is 30 rpm, add 3Kg of ingredients (0.2Kg of salt, 0.2Kg of monosodium glutamate, 1.0Kg of wheat germ powder, 0.8Kg of corn germ powder and 0.8Kg of soybean germ powder) , stir evenly, cool down to 60°C, stop stirring and heating for 40 minutes;

[0038] (5) Under the condition that the rotating speed is 25 rpm, continue stirring, and heat up to 100° C., and keep warm for 2 hours; ...

Embodiment 2A

[0044] A method for extracting animal fat, comprising the steps of:

[0045] (1) Under the condition that the rotating speed is 20 rpm, put 100Kg of pig adipose tissue into the reactor, heat up to 60°C, and keep the temperature for 3 hours;

[0046] (2) Under the condition that the rotating speed is 25 rpm, the temperature is raised to 83° C., and the temperature is kept for 1 hour;

[0047] (3) Add 12.5Kg of pork enzymatic hydrolyzed powder under the condition that the rotating speed is 30 rpm, heat up to 97°C, and keep warm for 3 hours;

[0048](4) Under the condition that the rotating speed is 30 rpm, add 3.5Kg of ingredients (salt of 0.1Kg, monosodium glutamate of 0.1Kg, wheat germ powder of 0.8Kg, corn germ powder of 1.3Kg and soybean germ powder of 1.2Kg ), stir evenly, cool down to 57°C, and stop stirring and heating for 30 minutes;

[0049] (5) Under the condition that the rotating speed is 25 rpm, continue stirring, and heat up to 97° C., and keep warm for 3 hours; ...

Embodiment 3A

[0055] A method for extracting animal fat, comprising the steps of:

[0056] (1) Under the condition that the rotating speed is 20 rpm, put 100Kg of pig adipose tissue into the reactor, heat up to 57°C, and keep the temperature for 5 hours;

[0057] (2) Under the condition that the rotating speed is 25 rpm, the temperature is raised to 77° C., and the temperature is kept for 3 hours;

[0058] (3) Under the condition that the rotation speed is 30 rpm, add 15Kg of pork enzymatic hydrolysis powder, heat up to 103°C, and keep warm for 1 hour;

[0059] (4) Under the condition that the rotating speed is 30 rpm, add 5Kg of ingredients (0.2Kg of salt, 0.3Kg of monosodium glutamate, 1.5Kg of wheat germ powder, 1.5Kg of corn germ powder and 1.5Kg of soybean germ powder) , stir evenly, cool down to 55°C, stop stirring and heating for 60 minutes;

[0060] (5) Under the condition that the rotating speed is 25 rpm, continue stirring, and heat up to 103° C., and keep warm for 1 hour;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com