Pure electric bus driving route planning method based on reverse order matching of battery capacity degeneration and working load

A battery capacity and workload technology, which is applied in the direction of measuring devices, surveying and navigation, road network navigators, etc., can solve problems that do not take into account the impact of battery electric bus operation economics and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0034] Concrete steps of the present invention are as follows:

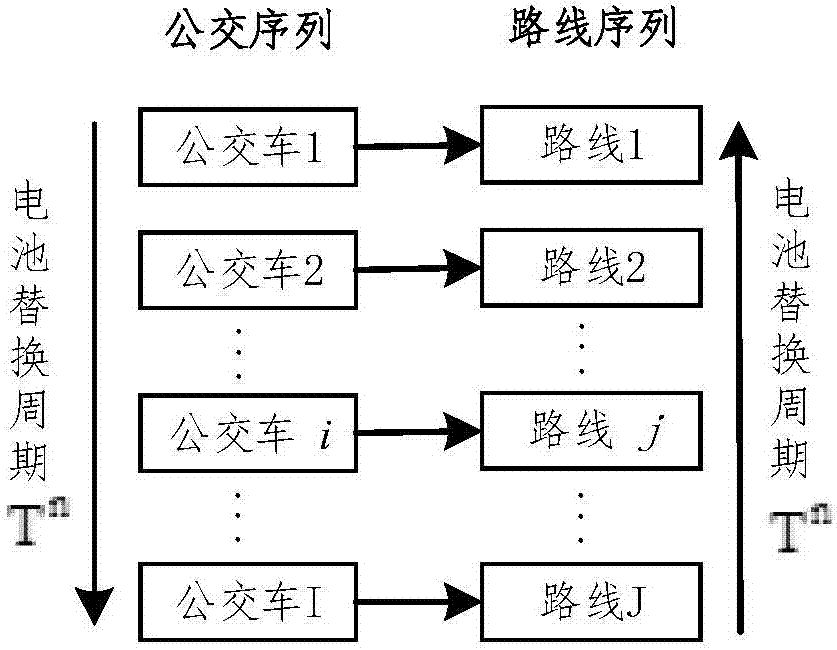

[0035] 1) First, assume that the pure electric bus runs on a fixed route and timetable, and each route runs several buses; each pure electric bus is equipped with the same power battery specification and capacity, and the pure electric bus runs from the depot every day The mileage from departure to return to the parking lot is less than the maximum mileage of the vehicle to ensure that the remaining power of the vehicle can be safely returned to the parking lot for charging, and it is only charged once a day during non-operating hours at night;

[0036] 2) Scheduling stage division of pure electric bus operation lines;

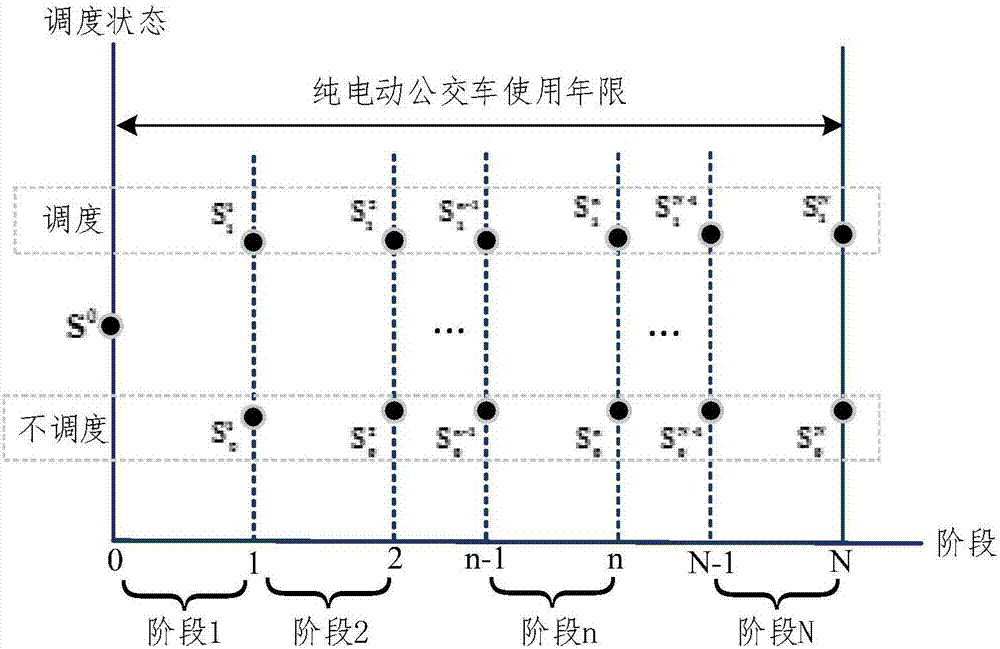

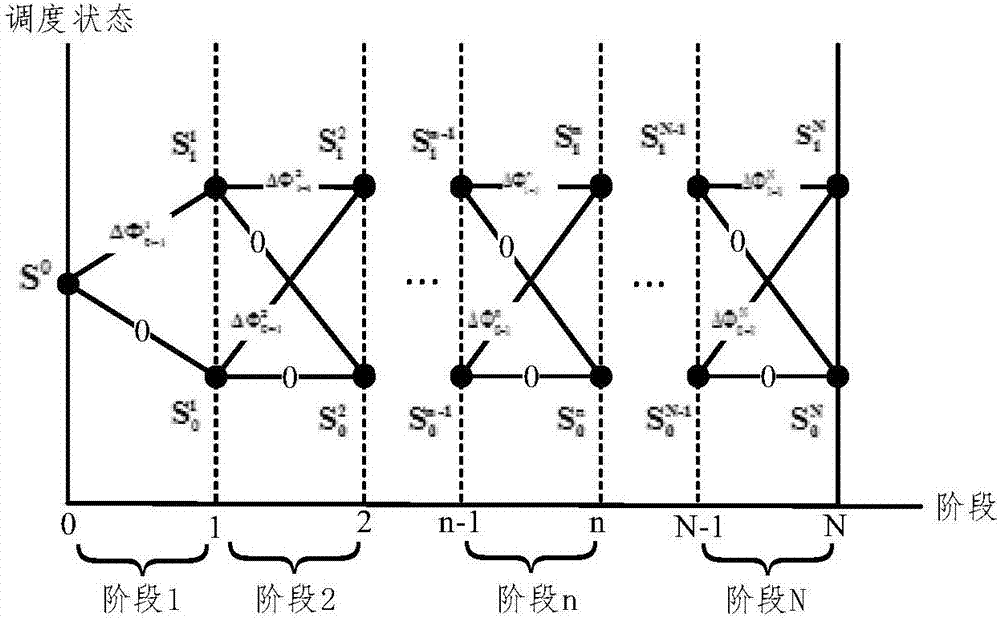

[0037] Such as figure 1 As shown, according to the service life of the pure electric bus, the minimum time unit of electric bus dispatching is defined as a stage, and the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com