Tea processing process

A processing technology and tea technology, applied in the field of tea preparation, can solve the problems of easy sticking to the bottom of the pan, time-consuming, small processing capacity, etc., and achieve the effects of reducing the degree of bending, avoiding a lot of damage, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

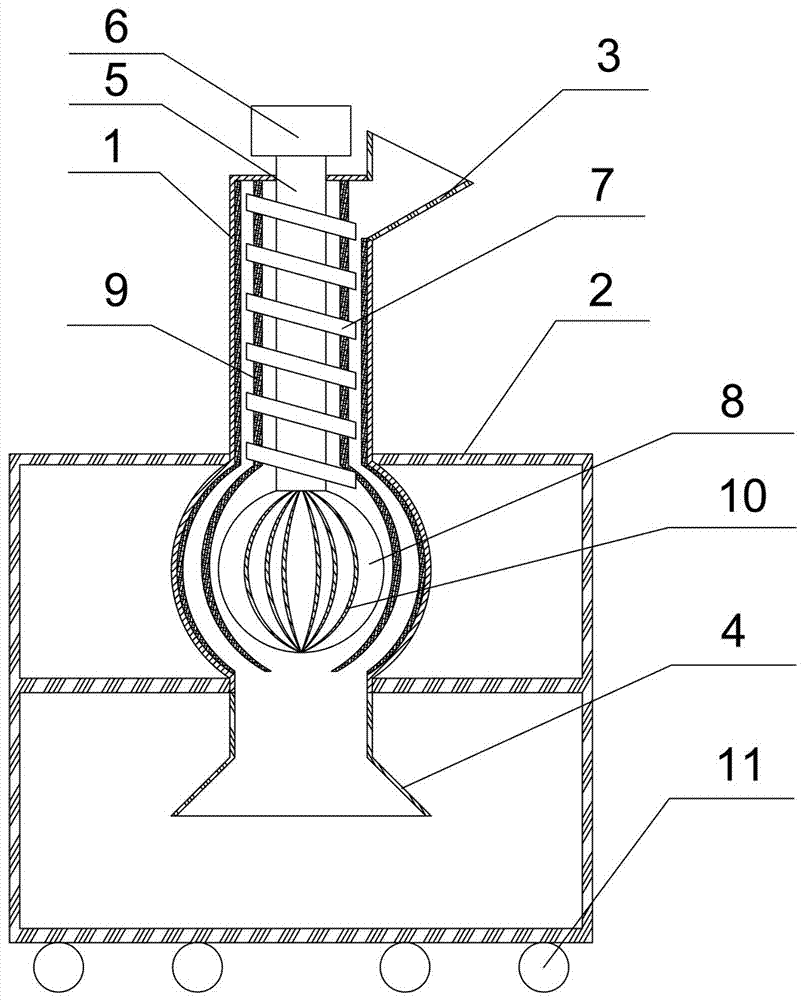

Image

Examples

Embodiment 1

[0026] A kind of tea processing technology, comprises the following steps:

[0027] a. Spread the fresh leaves: spread the fresh leaves of the tea tree for 6 hours, and the leaves must be spread;

[0028] b. Finishing: the spread leaves in step a are finished with a roller fixation machine, the finishing temperature is 150°C, the weight loss rate of finishing is 20%, and the green leaves are obtained;

[0029] c. Kneading: After the green leaves of step b are aired and regained moisture, use a kneading machine to knead for 15 minutes to get kneaded leaves;

[0030] d. Shaping: After the kneaded leaves in step c are cooled and regained moisture, use a rafting machine to trim and shape. The shaping temperature is 150°C, and the shaping time is 25 minutes, and the shaped leaves must be made;

[0031] e. Thinning and aroma: After cooling the shaped leaves in step d, use a bottle-type frying machine to fry the tea leaves until the moisture content of the tea leaves is 5%, and then...

Embodiment 2

[0033] A kind of tea processing technology, comprises the following steps:

[0034] a. Spread the fresh leaves: spread the fresh leaves of the tea tree for 4 hours before spreading the leaves;

[0035] b. Finishing: the spread leaves in step a are finished with a roller fixation machine, the finishing temperature is 120°C, the amount of leaf throwing is 2kg / min, the weight loss rate of finishing is 25%, and the green leaves are obtained;

[0036] c. Kneading: After the green leaves of step b are aired and regained moisture, use a kneading machine to knead and knead for 20 minutes with light pressure to obtain kneaded leaves;

[0037] d. Drying: Knead the leaf described in step c and roughen it with a dryer until the water content is 50%, so as to obtain the roughened leaf;

[0038] e. Shaping: After cooling and regaining moisture in the raw fire leaves in step d, use a rafting machine to trim and shape. The shaping temperature is 120°C, and the shaping time is 20 minutes, and...

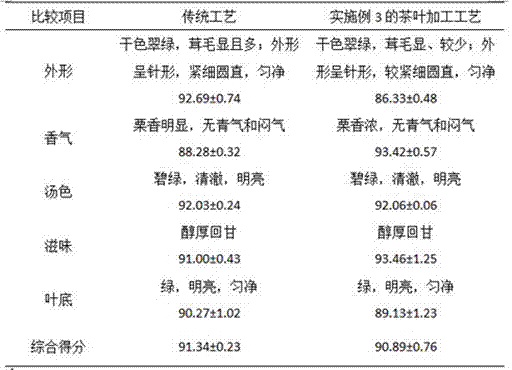

Embodiment 3

[0042] A kind of tea processing technology, comprises the following steps:

[0043] a. Spread the fresh leaves: spread the fresh leaves of the tea tree for 4 hours before spreading the leaves;

[0044] b. Finishing: the spread leaves in step a are finished with a roller fixation machine, the finishing temperature is 120°C, the amount of leaves thrown is 1.5kg / min, the weight loss rate is 30%, and the green leaves are obtained;

[0045] c. Kneading: After the green leaves of step b are aired and regained moisture, use a kneading machine to knead and knead for 20 minutes with light pressure to obtain kneaded leaves;

[0046] d. Drying: knead the leaf described in step c and roughen it with a dryer until the moisture content is 30%, so as to obtain the roughened leaf;

[0047] e. Shaping: After cooling and regaining moisture in the raw fire leaves in step d, use a rafting machine to trim and shape. The shaping temperature is 120°C, and the shaping time is 20 minutes, and the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com