Application of transition metal sulfide Mn-Cd-S-loaded solid solution in photocatalysis hydrogen production aspect

A transition metal and solid solution technology, applied in the direction of physical/chemical process catalysts, non-metallic elements, chemical instruments and methods, etc., can solve the problems of fast recombination rate, slow migration rate of photogenerated carriers, few composite catalysts or catalytic promoters Research and other issues, to achieve the effect of simple conditions, high commercial application prospects, and excellent photocatalytic hydrogen production activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

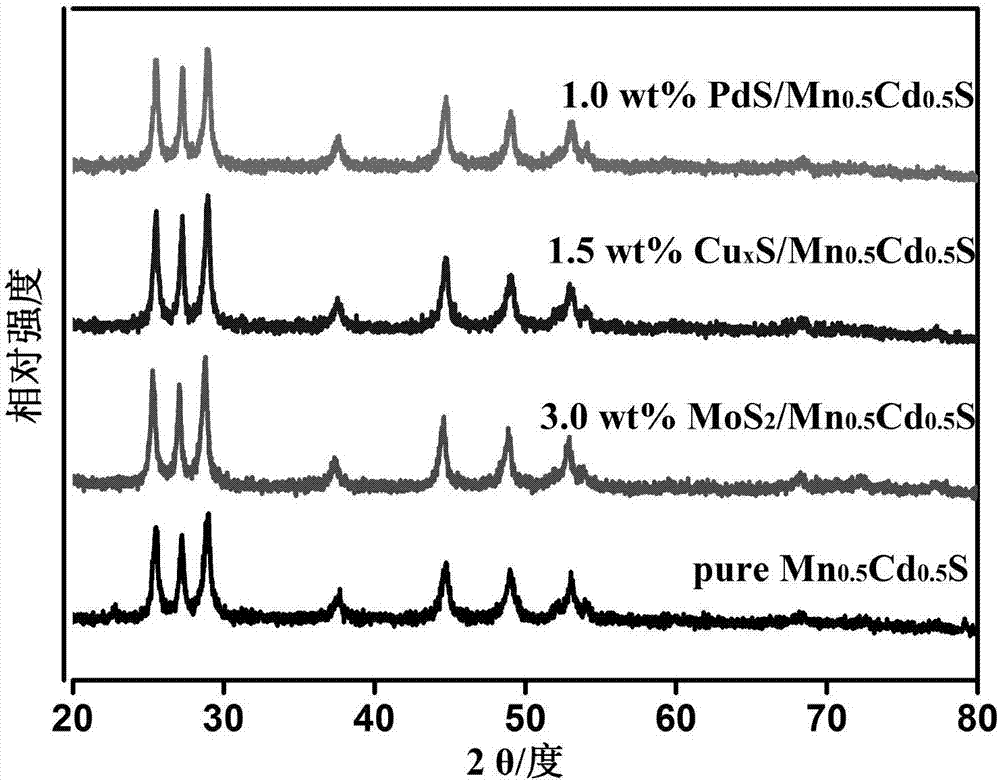

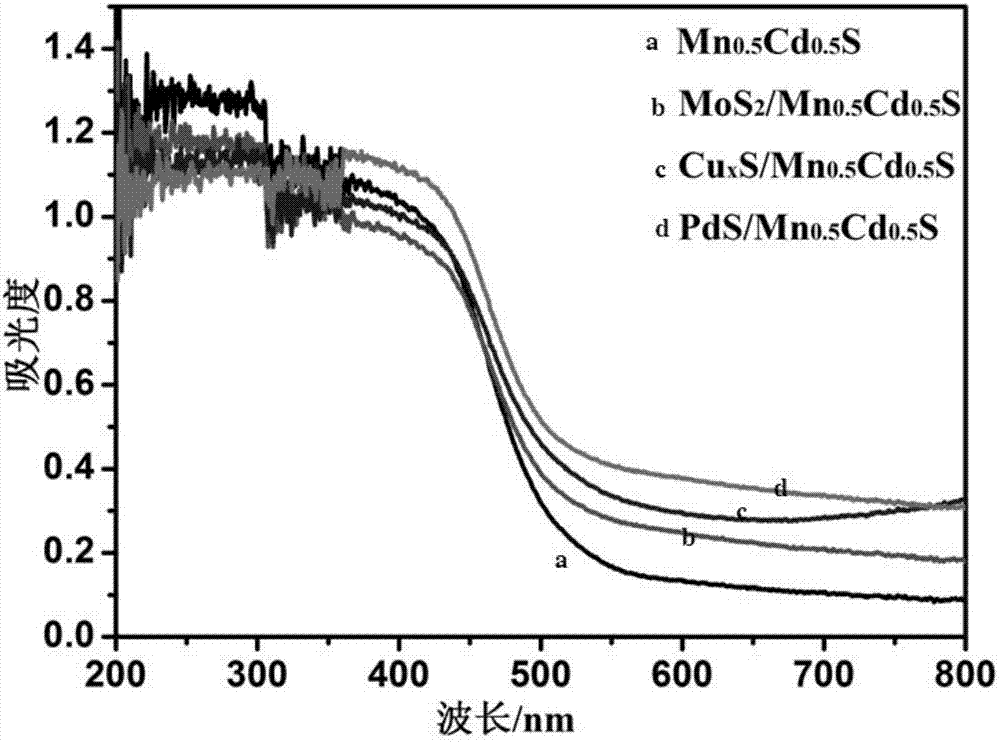

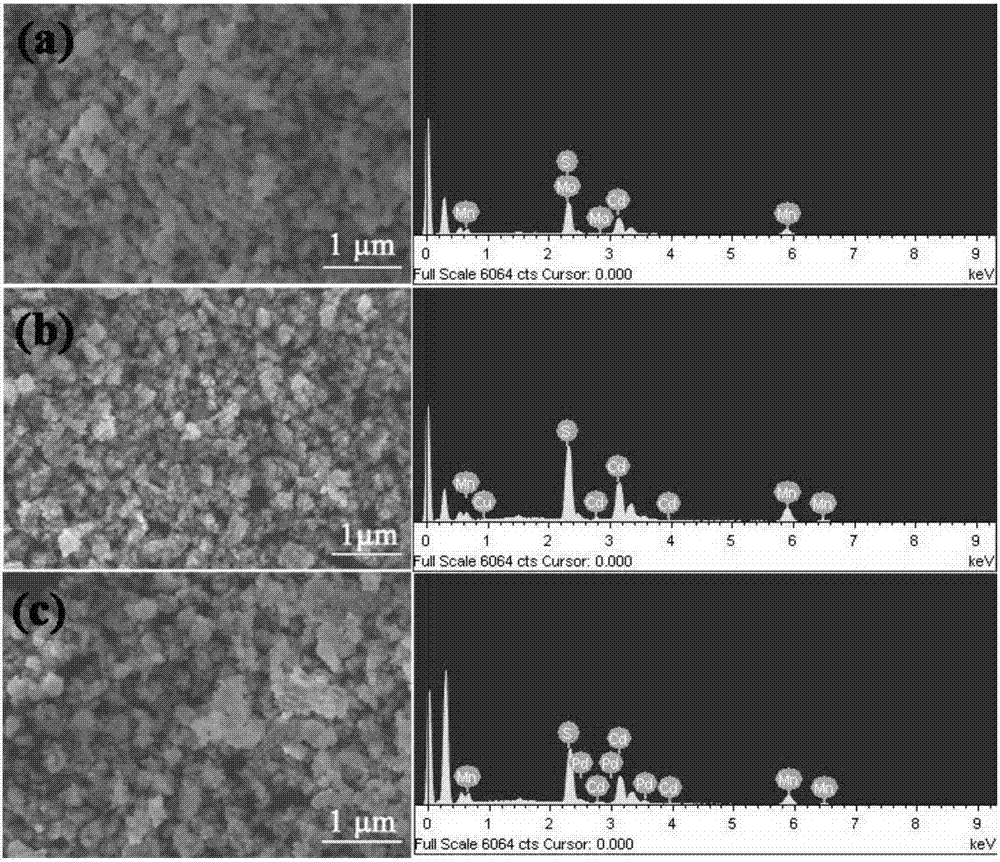

[0046] A specific embodiment of the present invention discloses XS / Mn 0.5 Cd 0.5 The preparation method of S(X=Mo, Cu, Pd) photocatalyst, the preparation method comprises: by photoreduction, in-situ loading in a way of transition metal sulfide XS(X=Mo, Cu, Pd) load to Mn 0.5 Cd 0.5 S solid solution.

[0047] Specifically, MoS 2 / Mn 0.5 Cd 0.5 S was prepared by photoreduction. Preferably, the photoreduction preparation method includes, Mn 0.5 Cd 0.5 S carrier dispersed in Na 2 S and Na 2 SO 3 to the mixture, and then add a certain amount of (NH 4 ) 2 MoS 4solution, stirred under light, the precipitate was separated and dried to obtain MoS 2 / Mn 0.5 Cd 0.5 S.

[0048] Cu x S / Mn 0.5 Cd 0.5 S was prepared by in situ loading method. Preferably, the method of in-situ loading includes, Mn 0.5 Cd 0.5 The S carrier was dispersed in water, and then a certain amount of Cu(NO 3 ) 2 The solution was stirred, and the precipitate was separated and dried to give Cu ...

Embodiment 1

[0057] Photocatalytic material XS / Mn 0.5 Cd 0.5 The preparation method of S (X=Mo, Cu, Pd), concrete steps are as follows:

[0058] (1) Preparation of Mn by hydrothermal method 0.5 Cd 0.5 S: First, measure 70ml of water with a measuring cylinder and pour it into a 150ml beaker, and weigh 0.245g of Mn(CH 3 COO) 2 4H 2 O and 0.207g Cd(CH 3 COO) 2 2H 2 O, put it into the above-mentioned beaker filled with water and stir to form a uniform aqueous solution, then weigh 1.11g of L-cystine and add it to the above solution under stirring, adjust the pH to 10.5 with 6mol / L NaOH, stir for 30min and then pipette In a 100 ml reactor, react at 130°C for 10 hours. Then, after the reactor was naturally cooled to room temperature, the precipitate was washed with deionized water for 2-3 times during suction filtration and dried at 60°C to obtain Mn 0.5 Cd 0.5 S solid solution powder.

[0059] (2)MoS 2 / Mn 0.5 Cd 0.5 S was prepared by photoreduction. mn 0.5 Cd 0.5 S carrier dis...

Embodiment 2

[0065] Photocatalytic material XS / Mn 0.5 Cd 0.5 The preparation method of S (X=Mo, Cu, Pd), concrete steps are as follows:

[0066] (1) Preparation of Mn by hydrothermal method 0.5 Cd 0.5 S: First, measure 70ml of water with a measuring cylinder and pour it into a 150ml beaker, and weigh 0.245g of Mn(CH 3 COO) 2 4H 2 O and 0.207g Cd(CH 3 COO) 2 2H 2 O, put it into the above-mentioned beaker filled with water and stir to form a uniform aqueous solution, then weigh 1.11g of L-cystine and add it to the above solution under stirring, adjust the pH to 10.5 with 6mol / L NaOH, stir for 30min and then pipette In a 100 ml reactor, react at 130°C for 10 hours. Then, after the reactor was naturally cooled to room temperature, the precipitate was washed with deionized water for 2-3 times during suction filtration and dried at 60°C to obtain Mn 0.5 Cd 0.5 S solid solution powder.

[0067] (2) Preparation of transition metal sulfide supported Mn 0.5 Cd 0.5 S photocatalyst:

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com