Halide perovskite-based platinum monatomic photocatalytic material as well as preparation method and application thereof

A technology of halide perovskite and photocatalytic materials, which is applied in the direction of catalyst activation/preparation, chemical instruments and methods, organic compound/hydride/coordination complex catalysts, etc., which can solve the problem of high preparation cost and cumbersome preparation process, etc. problem, to achieve the effect of low cost, good stability and excellent stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

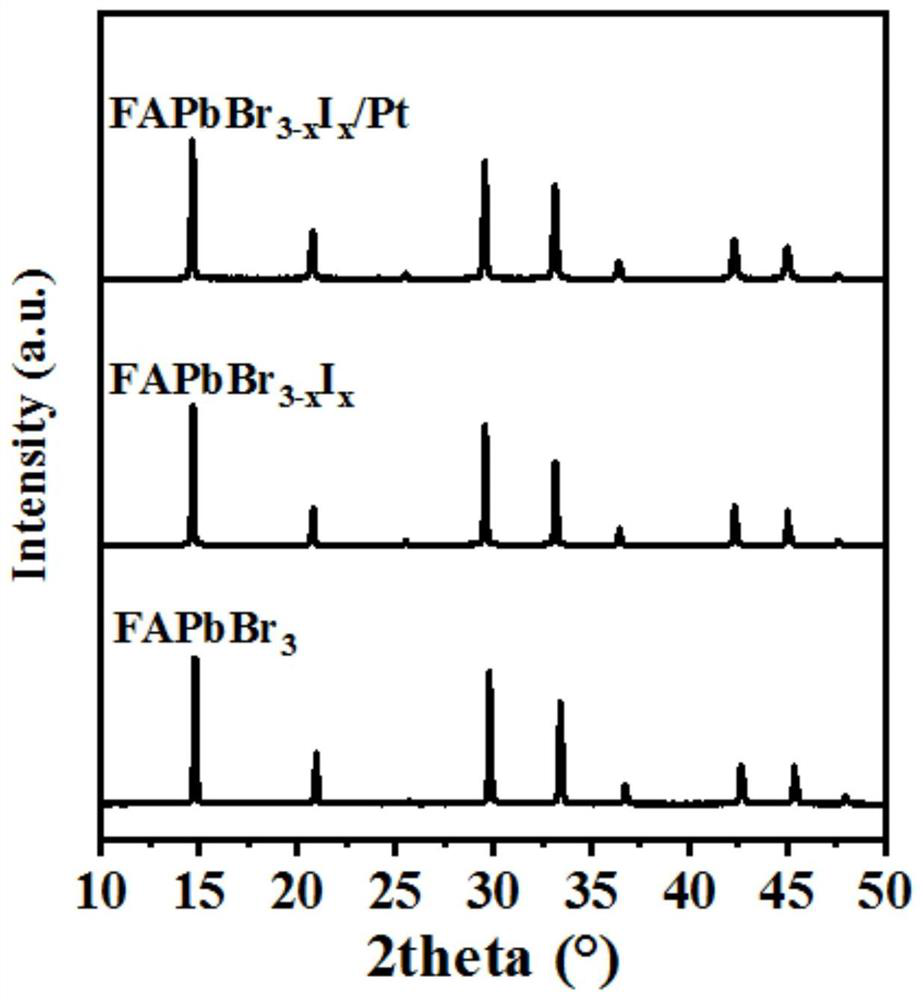

[0027] First, a method for preparing a halide perovskite-based platinum single-atom photocatalytic material, comprising the following steps:

[0028] Mixed halogen perovskite FAPbBr was prepared by co-precipitation or ion exchange method 3-x I x powder and saturated solution thereof, wherein x is 0-3;

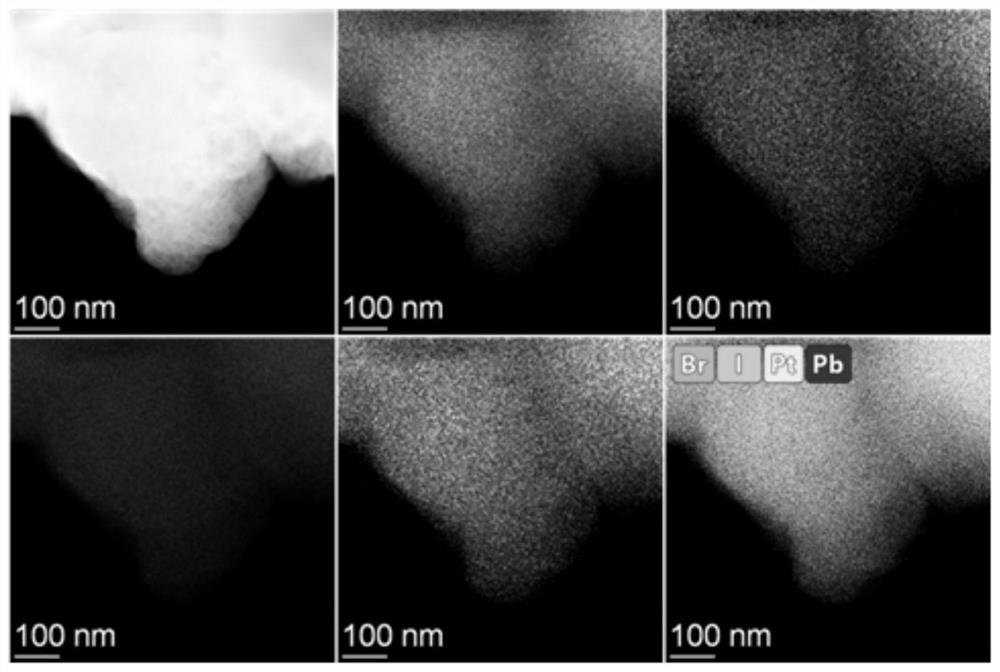

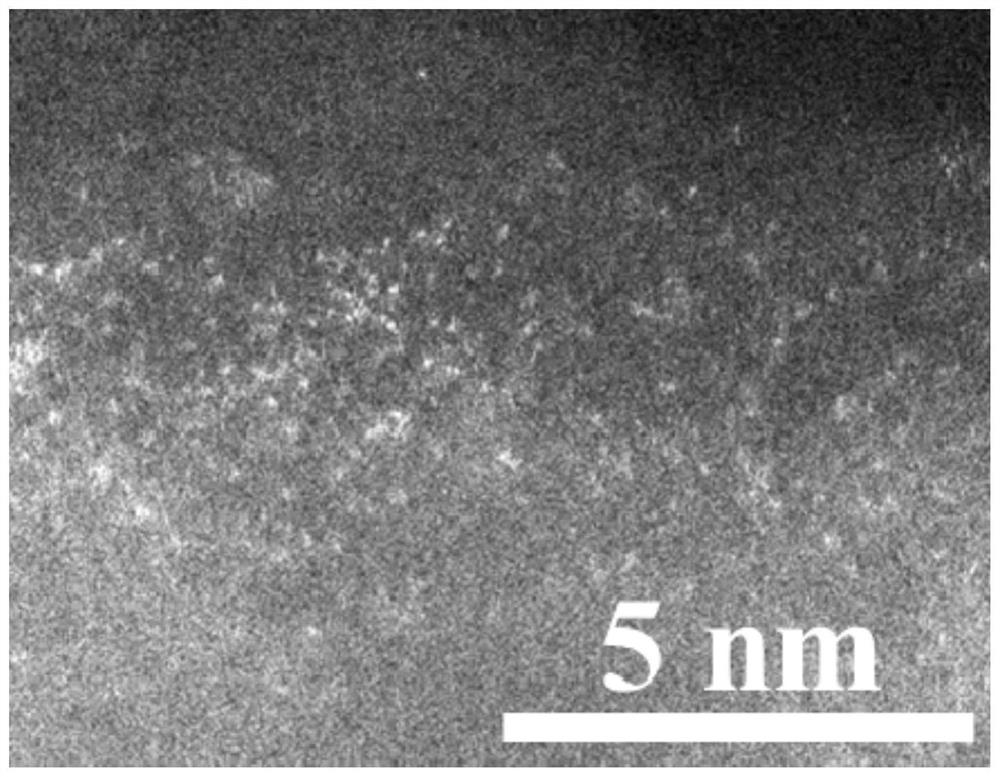

[0029] Mix the halogen perovskite FAPbBr 3-x I x The powder is dispersed in its saturated solution, and a platinum source is added to it, and after continuous stirring for a set time, the mixture is reacted under light, and the photoretrial reduction load of Pt is carried out to obtain a perovskite-based platinum single-atom catalytic material Pt / FAPbBr 3-x I x 。

[0030] In FAPbBr containing perovskite solutes 3-x I x Platinum sources (such as haloplatinic acid, haloplatinate, platinumate) are added to the saturated solution to anchor the Pt atom to the perovskite surface by adsorption and halogen coordination. The system is then illuminated, and a perovskite-supported atomic-leve...

Embodiment 1

[0055] Example 1: Preparation of FAPbBr by co-precipitation 3-x I x Mixed halogen perovskite photocatalytic material

[0056] The specific steps are as follows:

[0057]Take 40 mL hydroiodic acid and 10 mL hypophosphite in a 100 mL beaker with a measuring cylinder and heat it up to 90 °C; add 11.01 g of lead bromide and stir continuously, until it is completely dissolved, slowly add 4.296 g of methodine iodide and 0.625 g of formamidine bromide; stir for 30 minutes and then naturally cool to room temperature; filtration / centrifugal separation, the solution is a perovskite saturated solution, retained; the black powder is perovskite, 60 °C oven / vacuum drying to obtain the final FAPbBr 3-x I x Perovskite samples.

Embodiment 2

[0059] Take 40mL hydroiodic acid and 10mL hypophosphite in a 100mL beaker with a measuring cylinder and heat it up to 90 °C; add 9.175g of lead bromide and 2.305g of lead iodide and stir continuously, until it is completely dissolved, slowly add 5.157g of metamidine iodide; stir for 30 minutes and then naturally cool to room temperature; filter / centrifuge separation, the solution is the perovskite saturation solution, retained; the black powder is perovskite, 60 °C oven / vacuum drying to obtain the final FAPbBr 3-x I x Perovskite samples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com