A kind of solar photocatalytic porous glass and preparation method thereof

A technology of porous glass and solar light, applied in the field of photocatalysis, can solve the problems of low anatase phase content, reduce the photocatalytic activity of the film, and the coated glass does not have self-cleaning performance, so as to achieve controllable and controllable adjustment of the shape, Excellent photocatalytic performance, the effect of good photocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

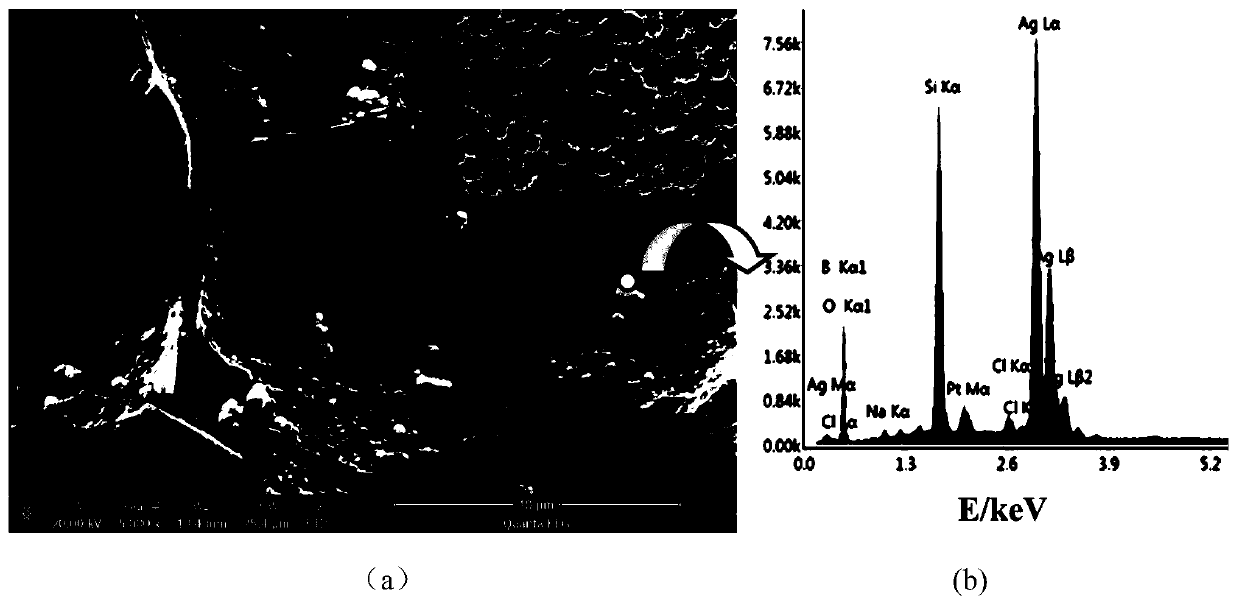

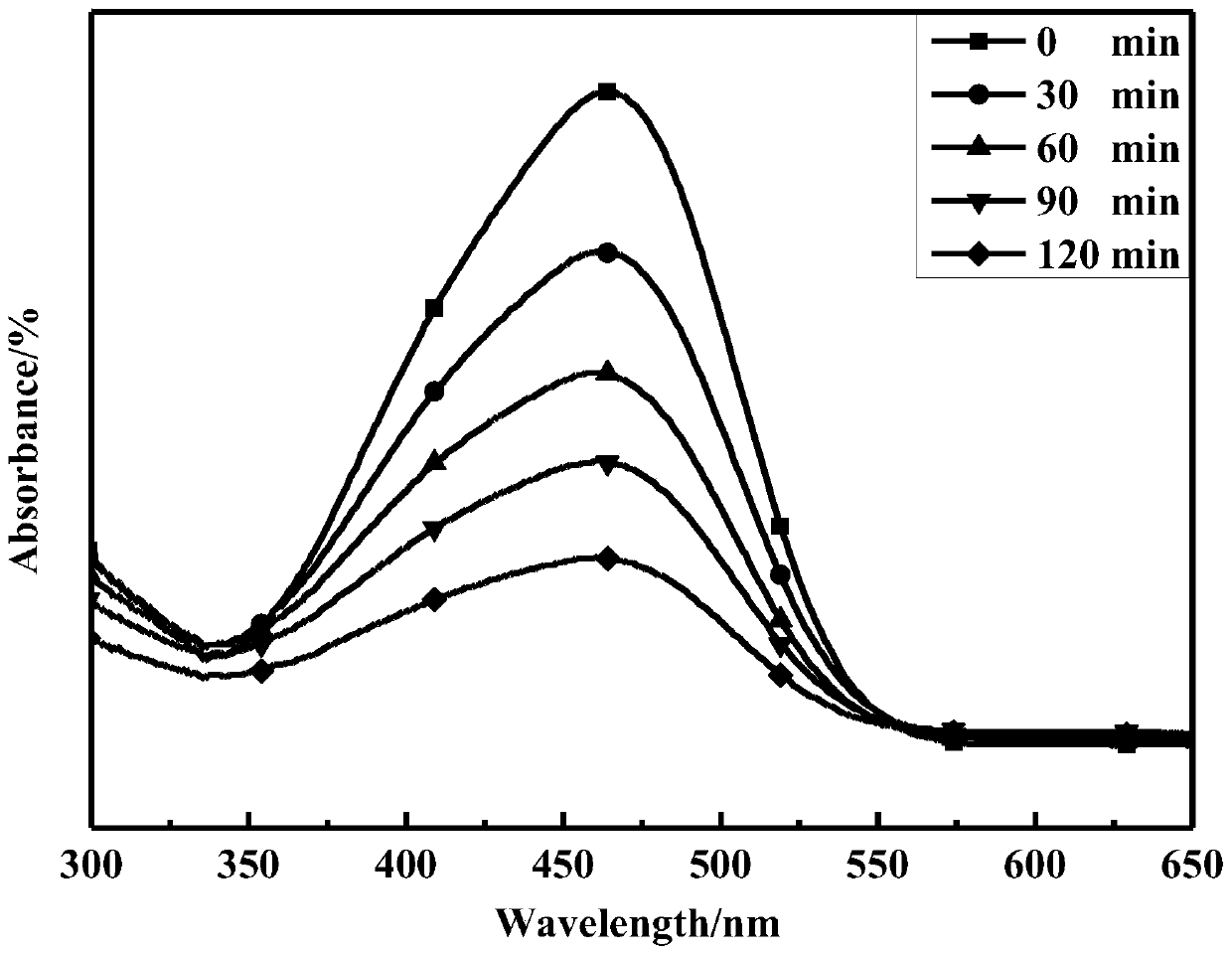

Embodiment 1

[0037] A kind of solar photocatalytic porous glass, its preparation method comprises the steps:

[0038] 1) Preparation of sodium borosilicate porous matrix glass: weigh each component of sodium borosilicate porous matrix glass according to the following mass percentage: SiO 2 63%, B 2 o 3 30%, Na 2 O 7%; which also doped with TiO 2 ,TiO 2The added amount is 1% of the total mass of each component; the weighed raw materials are mixed uniformly and fully ground to obtain the mixed raw materials; the obtained mixed raw materials are placed in a crucible and heated in an electric furnace at a heating rate of 2°C / min Warm at 1450°C for 1 hour for melting, the resulting molten glass is cast and annealed (keep at 550°C for 2 hours) to obtain sodium borosilicate glass; cut the obtained sodium borosilicate glass into sheets, polish and clean the surface to obtain The sodium borosilicate glass sheet is ready for use; put the obtained sodium borosilicate glass sheet into a muffle ...

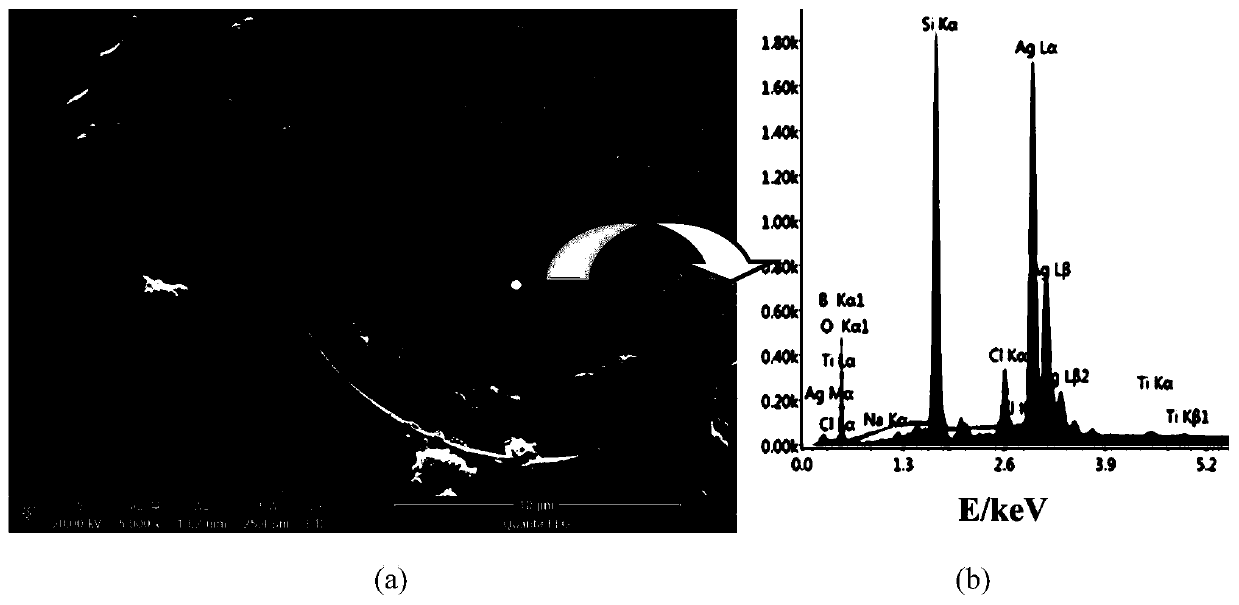

Embodiment 2

[0047] A kind of solar photocatalytic porous glass, its preparation method comprises the steps:

[0048] 1) Preparation of sodium borosilicate porous matrix glass: weigh each component of sodium borosilicate porous matrix glass according to the following mass percentage: SiO 2 62%, B 2 o 3 29%, Na 2 O 9%; which also doped with TiO 2 ,TiO 2 The added amount of the compound is 2% of the total mass of each component; the weighed raw materials are mixed uniformly and fully ground to obtain the mixed raw materials; the obtained mixed raw materials are placed in a crucible and heated in an electric furnace at a heating rate of 4°C / min Warm at 1460°C for 1 hour for melting, the resulting molten glass is cast and annealed (keep at 540°C for 2.5 hours) to obtain sodium borosilicate glass; cut the obtained sodium borosilicate glass into sheets, polish and clean the surface The obtained sodium borosilicate glass sheet is ready for use; the obtained sodium borosilicate glass sheet ...

Embodiment 3

[0057] A kind of solar photocatalytic porous glass, its preparation method comprises the steps:

[0058] 1) Preparation of sodium borosilicate porous matrix glass: weigh each component of sodium borosilicate porous matrix glass according to the following mass percentage: SiO 2 61%, B 2 o 3 31%, Na 2 O 8%; which also doped with TiO 2 ,TiO 2 The added amount is 3% of the total mass of each component; the weighed raw materials are mixed uniformly and fully ground to obtain the mixed raw materials; the obtained mixed raw materials are placed in a crucible and heated in an electric furnace at a heating rate of 4°C / min Warm at 1450°C for 2 hours for melting, the obtained glass liquid is cast and annealed (at 560°C for 3 hours) to obtain sodium borosilicate glass; cut the obtained sodium borosilicate glass into sheets, polish and clean the surface to obtain The sodium borosilicate glass sheet is ready for use; the obtained sodium borosilicate glass sheet is put into a muffle f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| energy | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com