Device for machining deformed steel bar roller transverse rib and electrical discharge machining method of deformed steel bar roll transverse rib

A technology of electric discharge machining and threaded steel, which is applied in the direction of accessory devices, electric processing equipment, metal processing equipment, etc., can solve the problem that the workpiece is difficult to process, and achieve the effect of overcoming burrs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

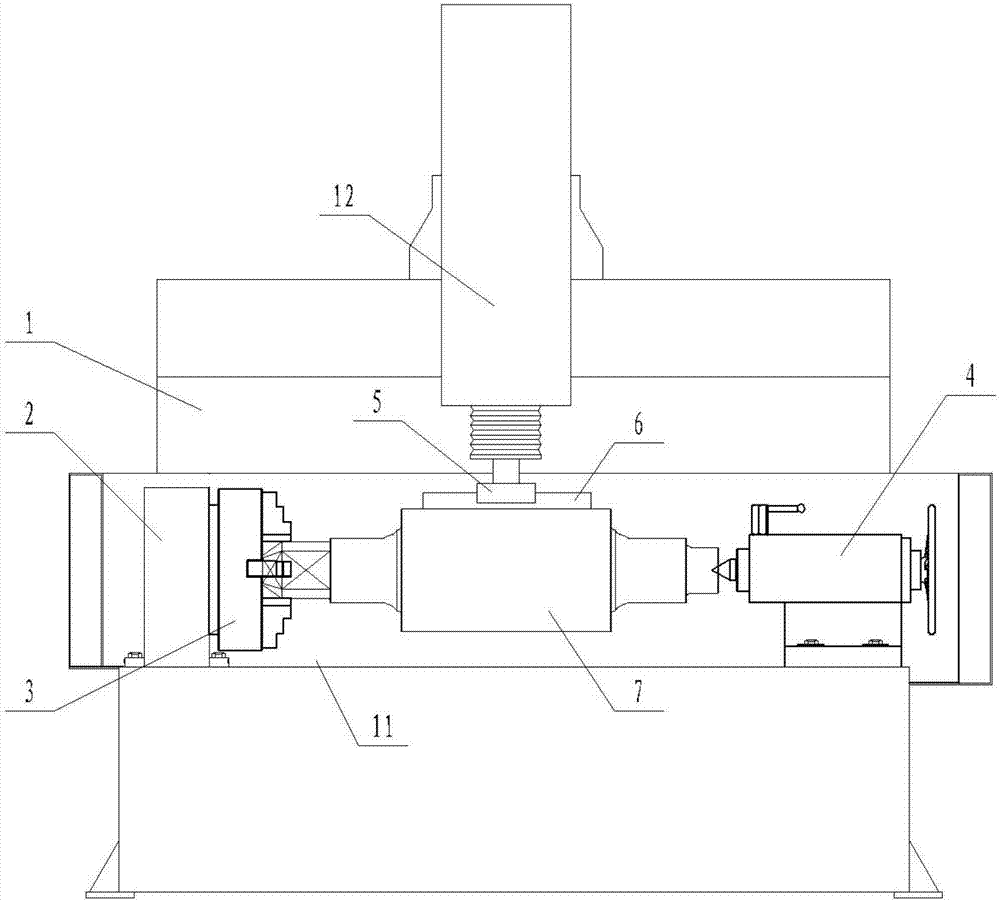

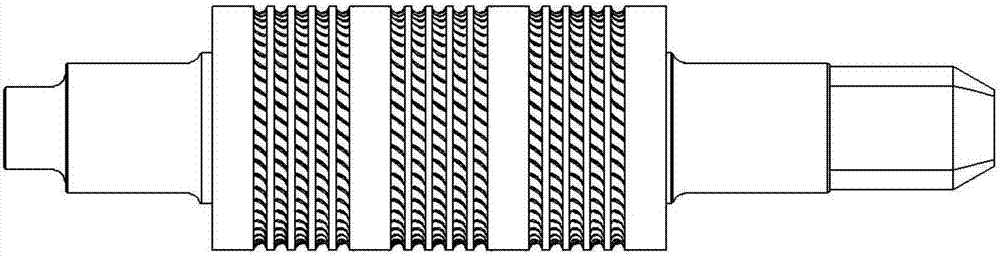

[0026] Reference attached figure 1 and figure 2 , which shows the basic structure of the device for processing the transverse ribs of the rebar roll provided by the embodiment of the present invention, and the structural schematic diagram of the rebar roll formed by the device for processing the transverse rib of the rebar roll.

[0027] The present embodiment provides a device for processing the transverse ribs of threaded steel rolls. The device includes: a spark machine 1, a numerically controlled index plate 2 and a tailstock 4 installed on the work table 11 of the spark machine 1, and a spark machine installed on the spark machine 1. The electrode clamping tool 5 at the lower end of the vertical axis 12 of the machine 1 is used to install the electrode 6; A chuck 3, a numerically controlled indexing plate 2, a chuck 3 and a tailstock 4 are arranged coaxially, and the chuck 3 and the tailstock 4 jointly fix the workpiece 7 to be processed.

[0028] Preferably, the elect...

Embodiment 2

[0030] This embodiment provides a method for electrical discharge machining of a transverse rib of a threaded steel roll, the electrical discharge machining method comprising the following steps:

[0031] (1), the workpiece 7 to be processed is fixed between the chuck 3 and the tailstock 4;

[0032] (2) According to the shape and size of the transverse rib, select the corresponding electrode 6, install the electrode 6 on the electrode clamping tool 5, and adjust the position so that the center of the electrode faces the position where the transverse rib needs to be processed on the upper part of the roller surface circumference ;

[0033] (3), EDM the first row of transverse ribs on the upper part of the threaded steel roll surface circumference, then rotate the numerical control indexing plate 2 predetermined angle clockwise or counterclockwise, and continue the electrical discharge machining of the second row of transverse ribs;

[0034] (4), repeat the operation of (3) ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com