An Adaptive Method for Robot Casting Grinding Based on Vision System

A vision system and robot technology, applied in the field of robot casting grinding adaptation based on vision system, can solve problems such as failure to detect and re-grind in time, and inability to guarantee the quality of grinding castings.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

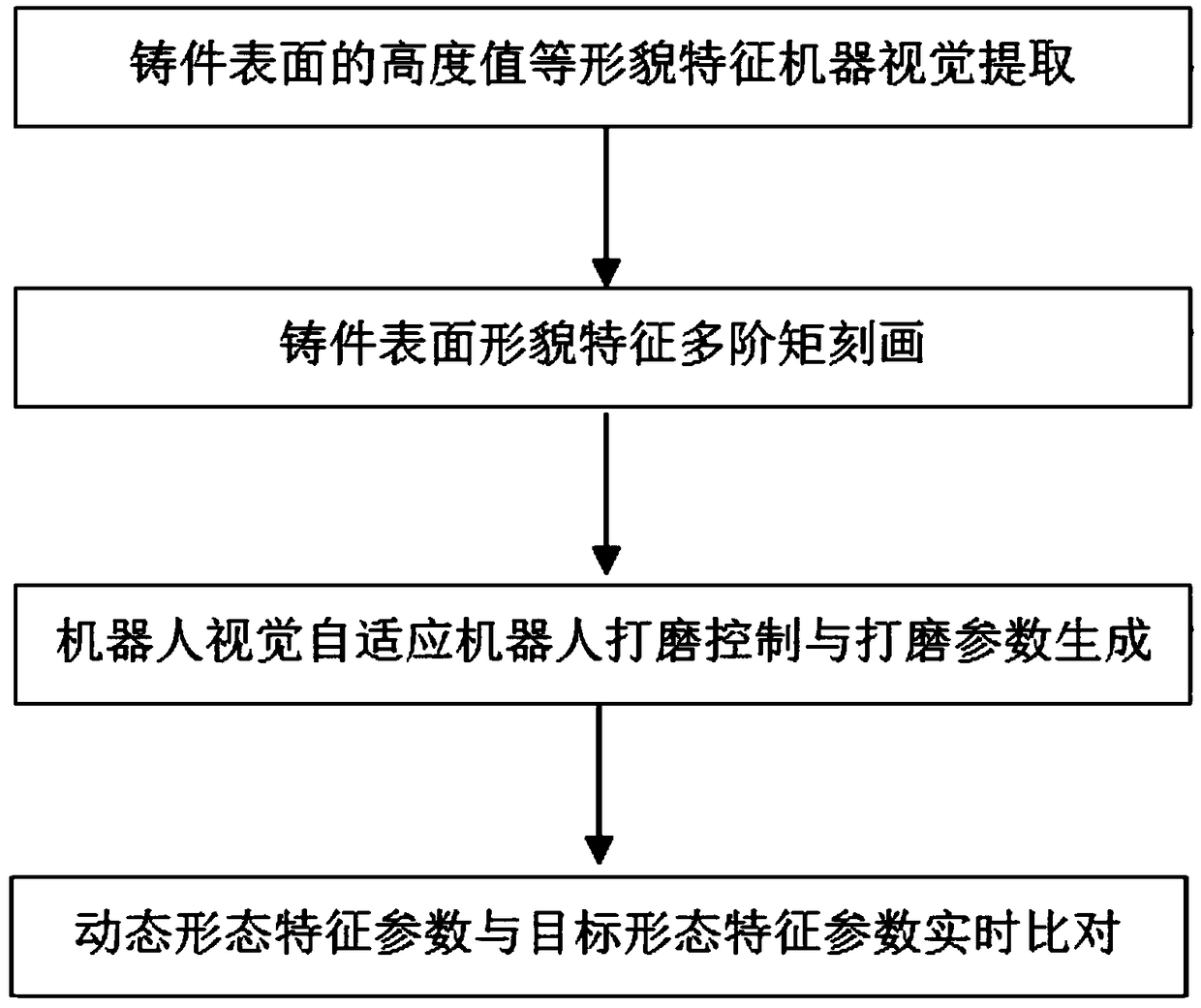

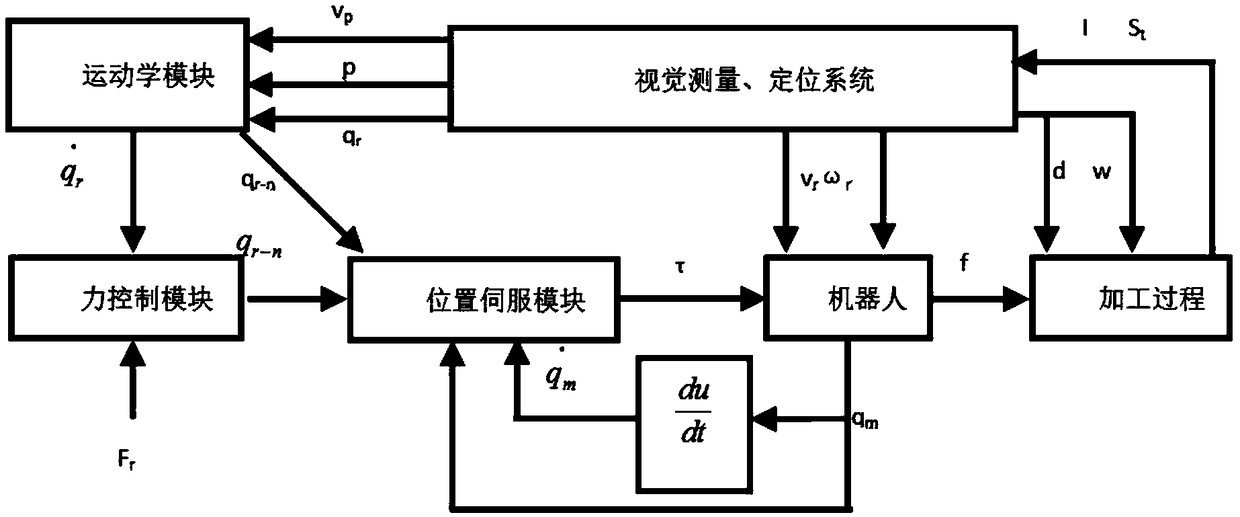

[0040] Such as figure 1 As shown, using an adaptive method for robot casting grinding based on the vision system, the HT300 cylinder casting with a weight of 38kg is automatically polished, and the volume of the casting is 400mm×320mm×253mm. The specific steps are as follows:

[0041] S01: Machine vision extraction of casting surface topography features:

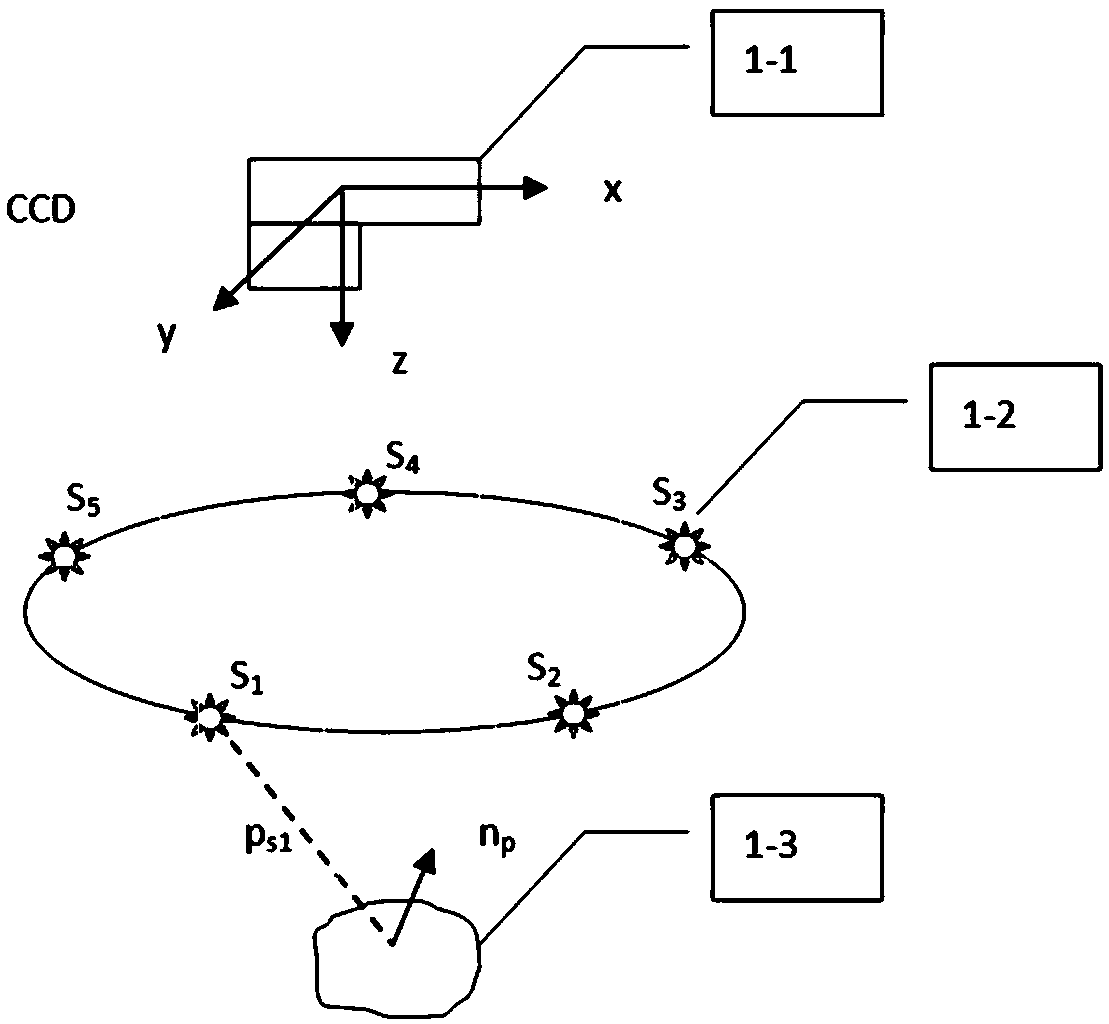

[0042] The processed workpiece is a 4-cylinder cylinder block, and the Panasoinc WV-CP410 / G CCD camera fixed above the cylinder block is used to capture the light image. The focal length of the camera is f=16mm, and the distance from the camera to the cylinder block is u=745mm. -1 to capture the illumination image, the light source (1-2) irradiates the casting surface photometric stereoscopic vision from different dire...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com