Mini-type driver and mechanical arm and running-in device thereof

A micro-driver and transmission mechanism technology, applied in the field of robotic arms, can solve the problems of no need to consider control lines, complex wiring of robotic arms, and low control accuracy, and achieve the effects of optimized mechanical design links, humanized appearance design, and high control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

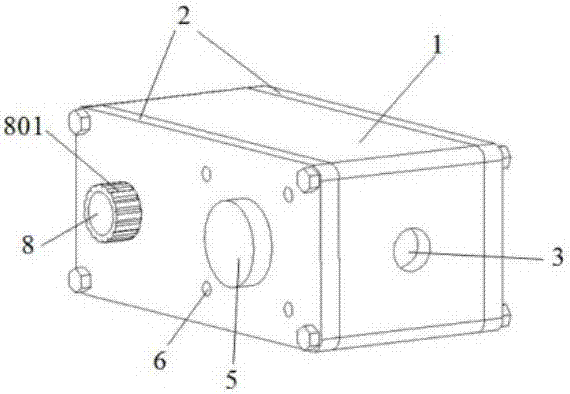

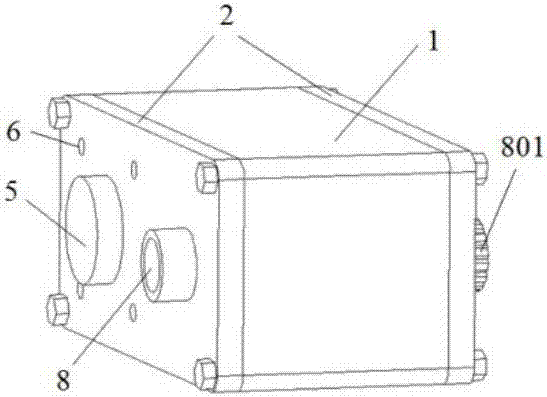

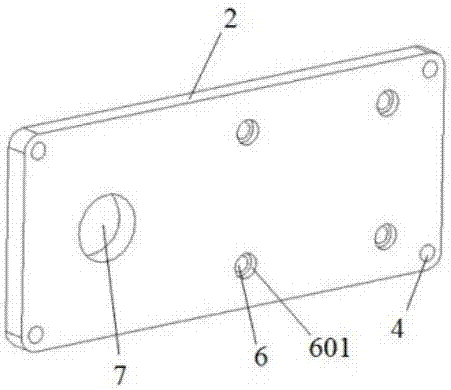

[0052] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described herein are only used to explain the present invention, but not to limit the present invention.

[0053] The micro-driver of the present invention is oriented to the application of small desktop robotic arms, and its installation size and signal connection mode are specially designed for the technical characteristics of desktop robotic arms, and are especially suitable for serial joint multi-degree-of-freedom robotic arms.

[0054] The micro-actuator of the present invention includes two types: swing-type micro-actuator and twist-type micro-actuator, wherein the swing-type micro-actuator is used for the swinging joint of the manipulator arm to realize the swing of the manipulator arm; the twist-type micro-actuator is used for the manipulator arm torsion joint , to realize the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com