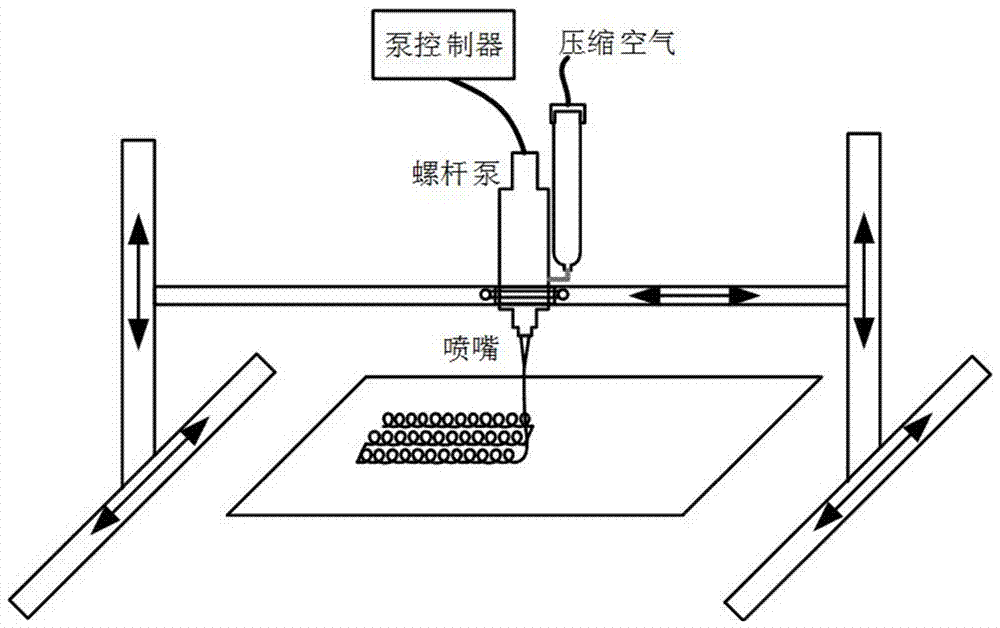

Porous elastic foam production method based on 3D printing of wet cured silica gel

An elastic foam, 3D printing technology, applied in the direction of processing and manufacturing, manufacturing auxiliary devices, liquid material additive processing, etc., can solve the problems of high bulk density, increased weight, low efficiency, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The processed foam material is a 25-layer porous elastic foam with an average layer height of 1.2 mm.

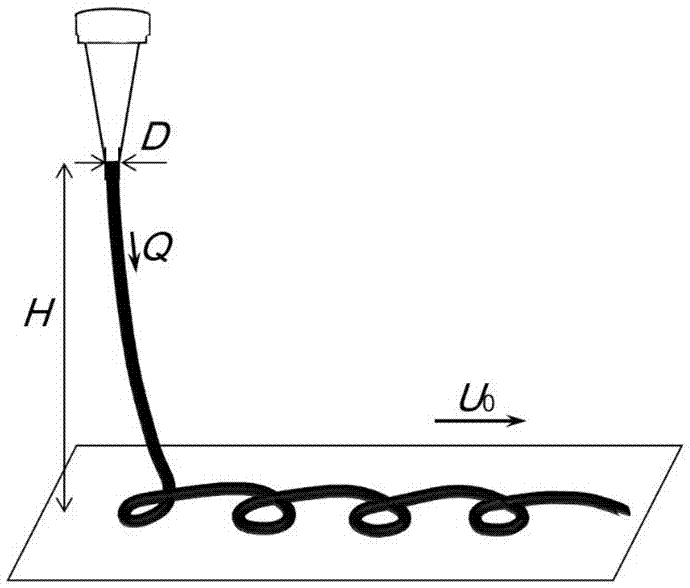

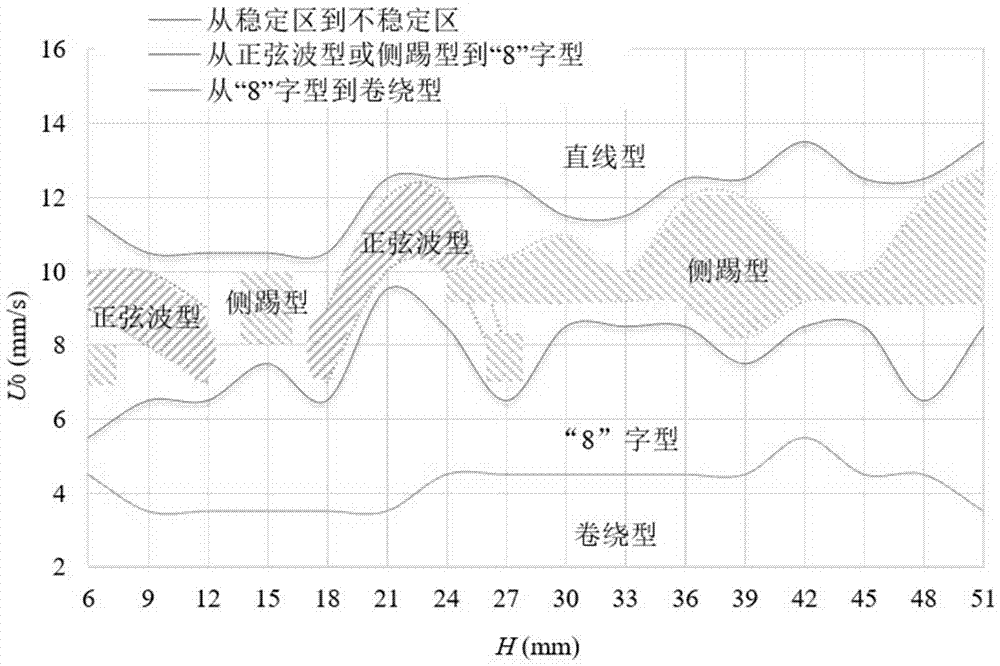

[0032] Among the process parameters, the silica gel viscosity R is 62.5Pa s, the silica gel spray flow rate Q is 0.12ml / min, the nozzle diameter D is 0.41mm, the nozzle height H is 12mm, and the nozzle moving speed (printing speed) U 0 is 2mm / s.

[0033] The patterns of each layer are composed of uniformly arranged strip-shaped winding patterns, and the patterns of two adjacent layers are arranged in a staggered state. The amplitude W of the winding pattern was 2.86 mm, the period length P was 1.4 mm, and the loop width T was 2.5.

[0034] see Figure 5 , the length a of each layer of material is 70 mm, the width b is 70 mm, and the distance d between two adjacent rows of patterns is 3 mm.

[0035] see Figure 6 As shown, according to the processing route, starting from the starting point, use the winding pattern to generate winding line 1 in the X direction. When...

Embodiment 2

[0038] The processed foam material is a 25-layer porous elastic foam with an average layer height of 0.75 mm.

[0039] Among the process parameters, the silica gel viscosity R is 62.5Pa s, the silica gel spray flow rate Q is 0.12ml / min, the nozzle diameter D is 0.41mm, the nozzle height H is 6mm, and the nozzle moving speed (printing speed) U 0 It is 3mm / s.

[0040] The patterns of each layer are composed of uniformly arranged strip-shaped winding patterns, and the patterns of two adjacent layers are arranged in a staggered state. The amplitude W of the winding pattern was 3.5 mm, the period length P was 2.7 mm, and the loop width T was 2.7 mm.

[0041] see Figure 5 , the length a of each layer of material is 70mm, the width b is 70mm, and the distance d between two adjacent rows of patterns is 3.5mm.

[0042] see Figure 6As shown, according to the processing route, start from the starting point, use the winding pattern to generate winding line 1 in the X direction, and ...

Embodiment 3

[0044] The processed foam material is a 25-layer porous elastic foam with an average layer height of 0.7mm.

[0045] Among the process parameters, the silica gel viscosity R is 62.5Pa s, the silica gel spray flow rate Q is 0.12ml / min, the nozzle diameter D is 0.41mm, the nozzle height H is 12mm, and the nozzle moving speed (printing speed) U 0 It is 3mm / s.

[0046] The patterns of each layer are composed of uniformly arranged strip-shaped winding patterns, and the patterns of two adjacent layers are arranged in a staggered state. The amplitude W of the winding pattern was 5 mm, the period length P was 3.84 mm, and the loop width T was 3.5 mm.

[0047] see Figure 5 , the length a of each layer of material is 70mm, the width b is 70mm, and the distance d between two adjacent rows of patterns is 5mm.

[0048] see Figure 6 As shown, according to the processing route, start from the starting point, use the winding pattern to generate winding line 1 in the X direction, and whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com