On-site production and construction device for waterproofing treatment

A construction device and technology on the other side, applied in lamination devices, layered products, lamination auxiliary operations, etc., can solve the problems of difficult to fully bond the base surface, general crack resistance, etc., to overcome air holes and waterproof Effect improvement, effect with less garbage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to enable those skilled in the art to better understand the technical solutions in this application, the technical solutions in this application will be clearly and completely described below in conjunction with embodiments.

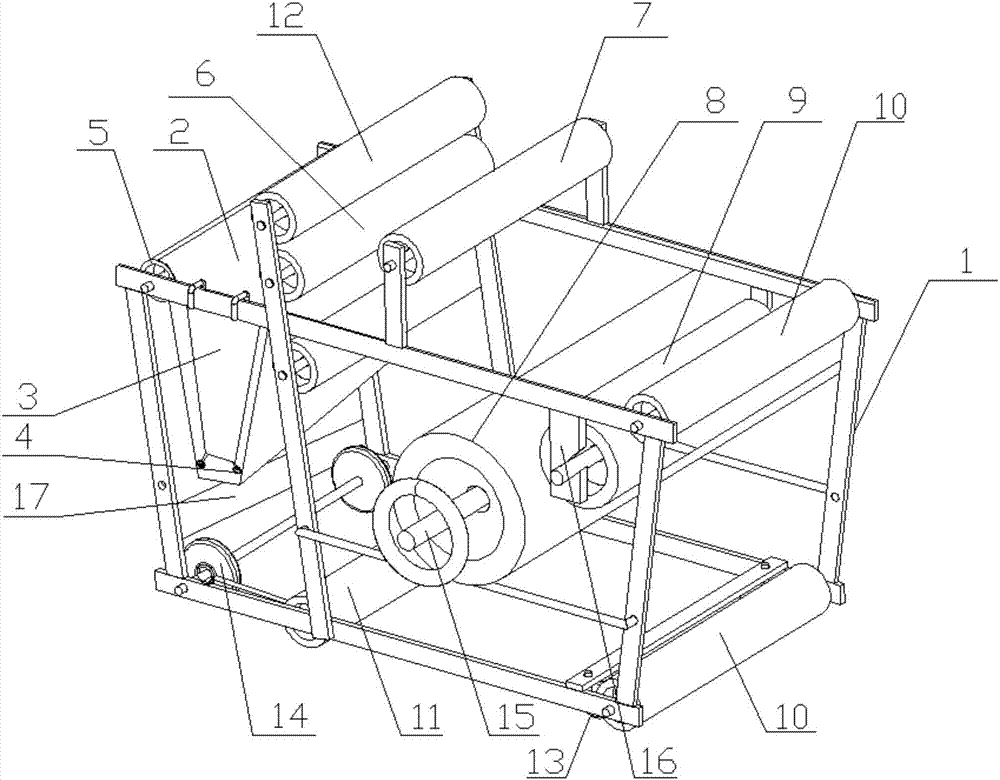

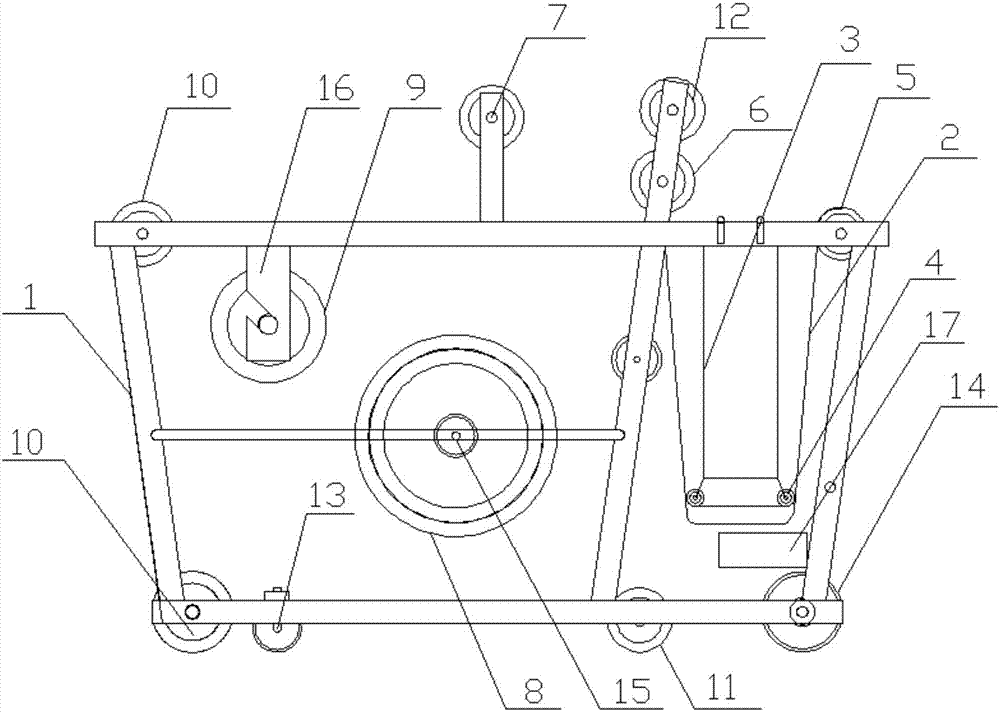

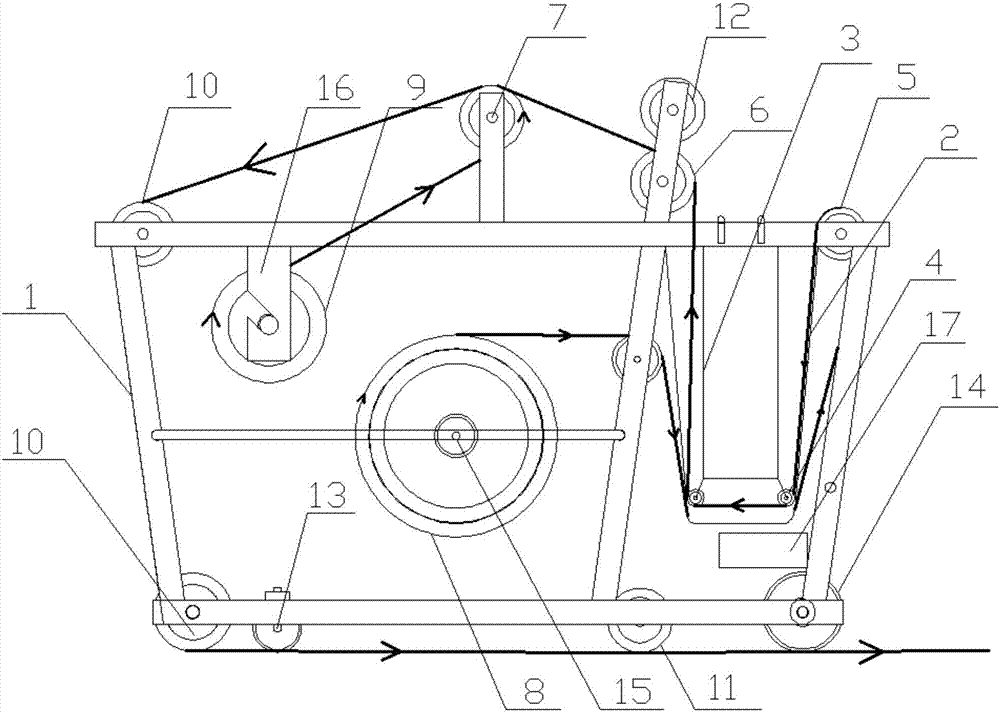

[0019] Such as Figure 1-Figure 2 As shown, the present invention discloses a waterproof on-site production and construction device, including a vehicle frame 1, an oil pan 2 and an oil immersion frame 3 are arranged on one side of the vehicle frame 1, and an immersion oil frame 3 is provided on the oil immersion frame 3. The oil roller 4 and the oil soaking roller 4 are located at the bottom of the oil pan 1; the end of the frame 1 located on one side of the oil pan 2 is provided with a lickering roller 5, and the frame 1 located on the other side of the oil pan 2 is provided with a transmission roller 6 , the driving roller 6 is provided with a film-coated roller 7; the middle part of the vehicle frame 1, the bottom of the film-coated r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com