High-color-rendering quantum dot fluorescent powder film and preparation method thereof

A quantum dot and phosphor technology, which is applied in the field of high color rendering quantum dot phosphor film and its preparation, can solve the problems of low efficiency of red phosphor, complex chip drive circuit, and development constraints of high CRI LED, and achieve high The effect of color rendering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

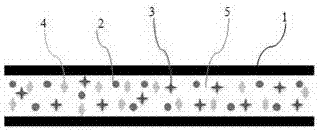

[0044] A method for preparing a high color rendering quantum dot phosphor film, the process steps are as follows:

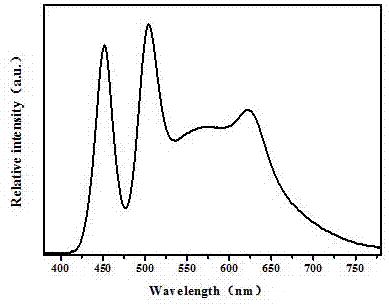

[0045] a. Weigh a certain amount of CdSe / CdS / ZnS red light quantum dots with a peak emission wavelength of 626nm, and a certain amount of CdSe@ZnS / ZnS blue-green quantum dots with a peak emission wavelength of 493nm (red and blue-green quantum dots are provided by the company Quantum According to the mass ratio of red light quantum dots and organic solvent is 1:17, and the mass ratio of blue-green light quantum dots and organic solvent is 1:2, add appropriate amount to red light quantum dots and blue-green light quantum dots respectively organic solvent PhMe (toluene);

[0046] b. Put the red light quantum dot solution and the blue-green light quantum dot solution obtained in step a into an ultrasonic cleaner for ultrasonic treatment, control the water bath temperature of the ultrasonic cleaner to 35°C, ultrasonic frequency 70 KHZ, and ultrasonic treatment time 3...

Embodiment 2

[0051] The gist of the present invention is to provide a kind of preparation method of high color rendering property quantum dot phosphor film, described process step is as follows:

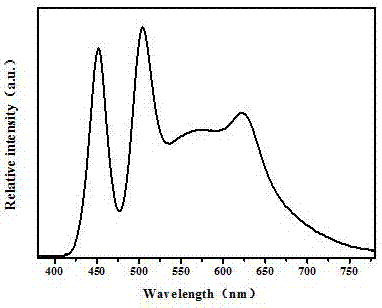

[0052] a. Weigh a certain amount of CdSe / CdS / ZnS red light quantum dots with a peak emission wavelength of 626nm, and a certain amount of CdSe@ZnS / ZnS blue-green quantum dots with a peak emission wavelength of 493nm (red and blue-green quantum dots are provided by the company Quantum According to the mass ratio of red light quantum dots and organic solvent is 1:17, and the mass ratio of blue-green light quantum dots and organic solvent is 1:2, add appropriate amount to red light quantum dots and blue-green light quantum dots respectively organic solvent PhMe (toluene);

[0053] b. Put the red light quantum dot solution and the blue-green light quantum dot solution obtained in step a into an ultrasonic cleaner for ultrasonic treatment, control the water bath temperature of the ultrasonic cleaner t...

Embodiment 3

[0058] A method for preparing a high color rendering quantum dot phosphor film, the process steps are as follows:

[0059] a. Weigh a certain amount of CdSe / CdS / ZnS red light quantum dots with a peak emission wavelength of 626nm, and a certain amount of CdSe@ZnS / ZnS blue-green quantum dots with a peak emission wavelength of 493nm (red and blue-green quantum dots are provided by the company Quantum According to the mass ratio of red light quantum dots and organic solvent is 1:17, and the mass ratio of blue-green light quantum dots and organic solvent is 1:2, add appropriate amount to red light quantum dots and blue-green light quantum dots respectively organic solvent PhMe (toluene);

[0060] b. Put the red light quantum dot solution and the blue-green light quantum dot solution obtained in step a into an ultrasonic cleaner for ultrasonic treatment, control the water bath temperature of the ultrasonic cleaner to 35°C, ultrasonic frequency 70KHZ, and ultrasonic treatment time 30...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com