No-ink silk screen printing method and application thereof

A technology of screen printing and ink, applied in the direction of printing, production of special varieties of printed matter, printing process, etc., can solve problems such as ink pollution, and achieve the effect of high concealment, low cost and simple transfer process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The printing steps of this embodiment are as follows:

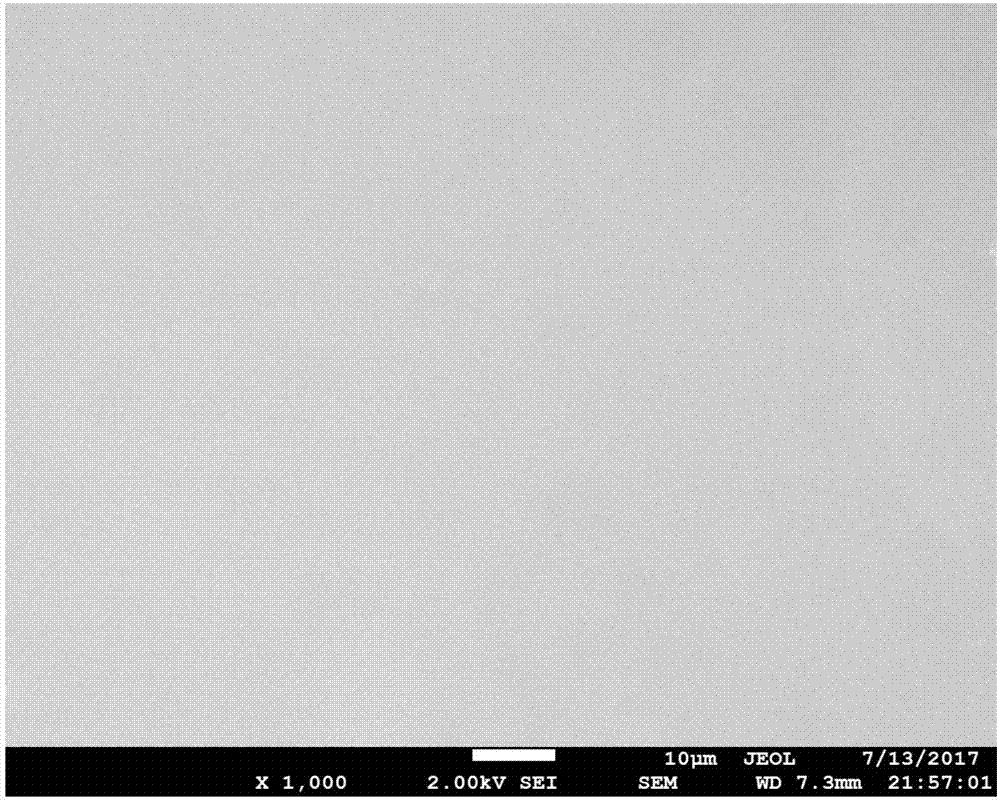

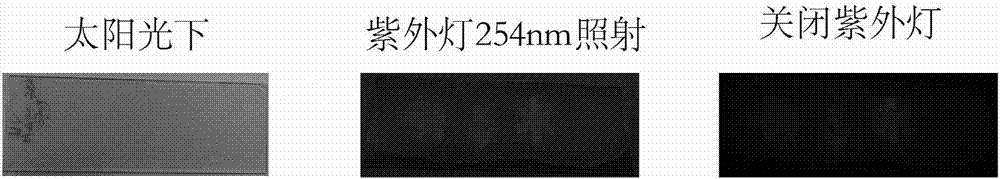

[0028] Weigh 0.1g of polyvinyl alcohol (PVA) into a round bottom flask, add 10ml of deionized water, raise the temperature to 95°C with stirring and keep it for 1.5h to obtain a 10g / L PVA aqueous solution, and then add 10mg of potential phosphor six -(3-carboxy-phenoxy)-cyclotrimeric phosphazene is doped into the PVA solution, and after mixing uniformly, it is prepared to obtain a mixed solution with a mass fraction of 9.1% (the said mass fraction in the present invention is six-(3 -carboxy-phenoxy)-cyclotrimeric phosphazene as a percentage of the sum of hexa-(3-carboxy-phenoxy)-cyclotrimeric phosphazene and polyvinyl alcohol) on glass by drop coating Form a film and bake it at 60°C for 3 hours to obtain a uniform film material, then transfer the screen printing plate to the prepared film, and irradiate the pattern with a 254nm ultraviolet lamp for 25 minutes to complete the printing process.

Embodiment 2

[0030] The printing steps of this embodiment are as follows:

[0031] Weigh 0.1g of polyvinyl alcohol (PVA) in a round bottom flask, add 10ml of deionized water, raise the temperature to 90°C with stirring and keep it for 2h to obtain a 10g / L PVA aqueous solution, and then add 30mg of potential phosphor hexa- (4-Carboxyl-phenoxy)-cyclotrimeric phosphazene was doped into the PVA solution, and after mixing evenly, a mixed solution with a mass fraction of 23.1% was prepared, and a film was formed on the glass by the drop coating method, and was heated at 100°C Bake for 1.5 hours to obtain a uniform film material, then transfer the screen printing plate to the prepared film, and irradiate the pattern with a 254nm ultraviolet lamp for 100 minutes to complete the printing process.

Embodiment 3

[0033] The printing steps of this embodiment are as follows:

[0034] Weigh 0.1g of polyvinyl alcohol (PVA) in a round bottom flask, add 10ml of deionized water, raise the temperature to 85°C under stirring and keep it for 4h to obtain a 10g / L PVA aqueous solution, and then add 50mg of potential phosphor six- (2-Carbomethoxy-phenoxy)-cyclotrimeric phosphazene was doped into the PVA solution, and after mixing evenly, a mixed solution with a mass fraction of 33.3% was prepared, and a film was formed on the glass by spin coating, and the Bake at 80°C for 2 hours to obtain a uniform film material, then transfer the screen printing plate to the prepared film, and irradiate the pattern with a 280nm ultraviolet lamp for 60 minutes to complete the printing process.

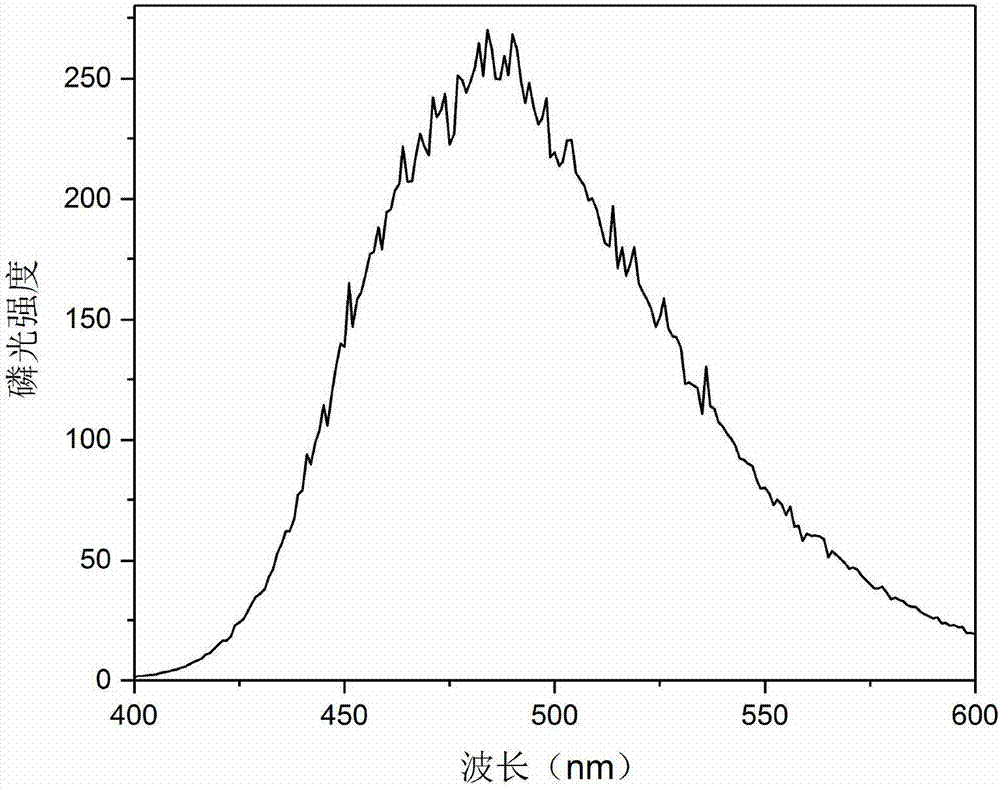

[0035] figure 1 and Figure 4 Be respectively the room temperature phosphorescence spectrum of the printed pattern of embodiment 1 and embodiment 2, by figure 1 and Figure 4 It can be seen that the thin film prepared...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com