Aluminum cell self-adaptation crust breaking device

A shell-breaking device and self-adaptive technology, which is applied in the field of measurement and control, can solve the problems of large fluctuation range of cell voltage, lower current efficiency, and damage to the thermal balance of the electrolytic cell, etc., and achieve strong environmental adaptability, simple and universal process, and mature and reliable technology Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, rather than limiting the protection scope of the present invention.

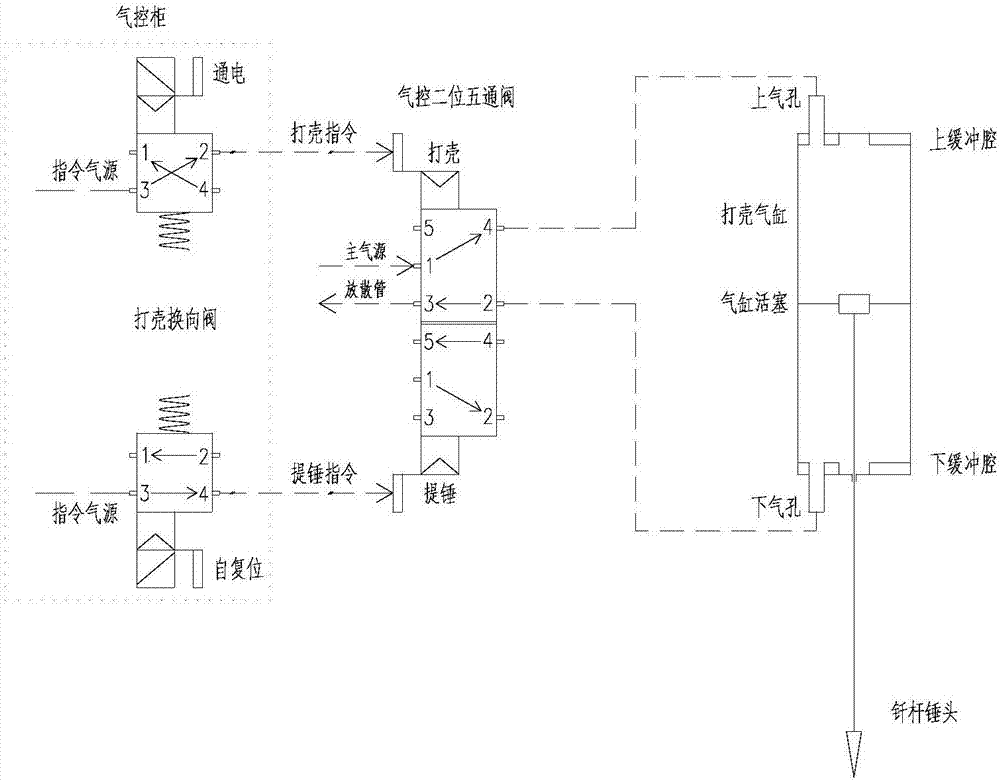

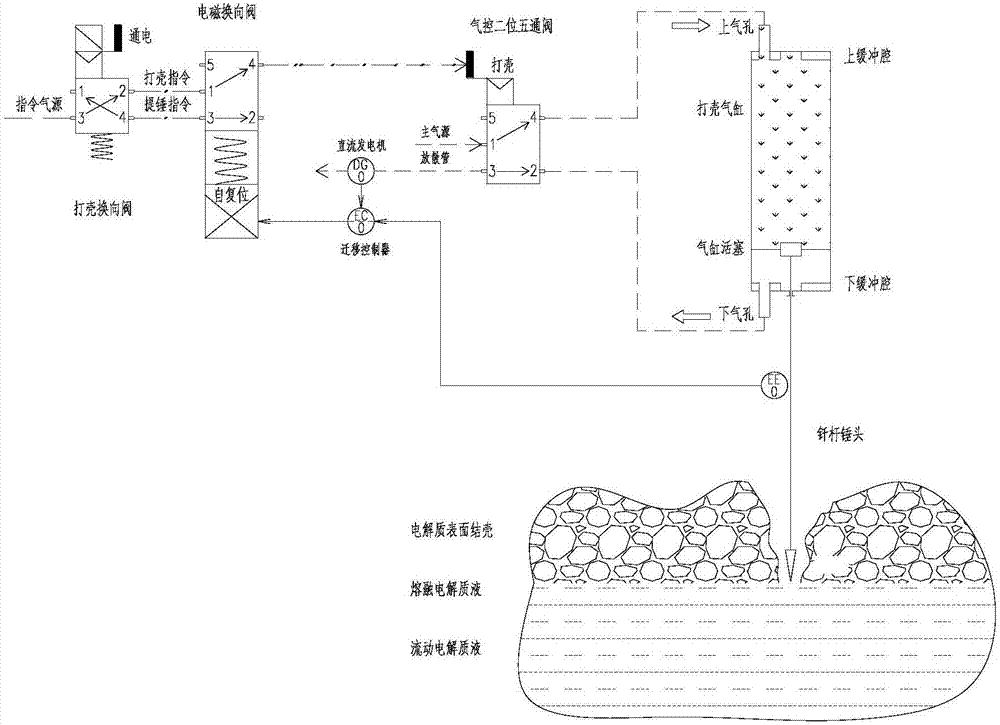

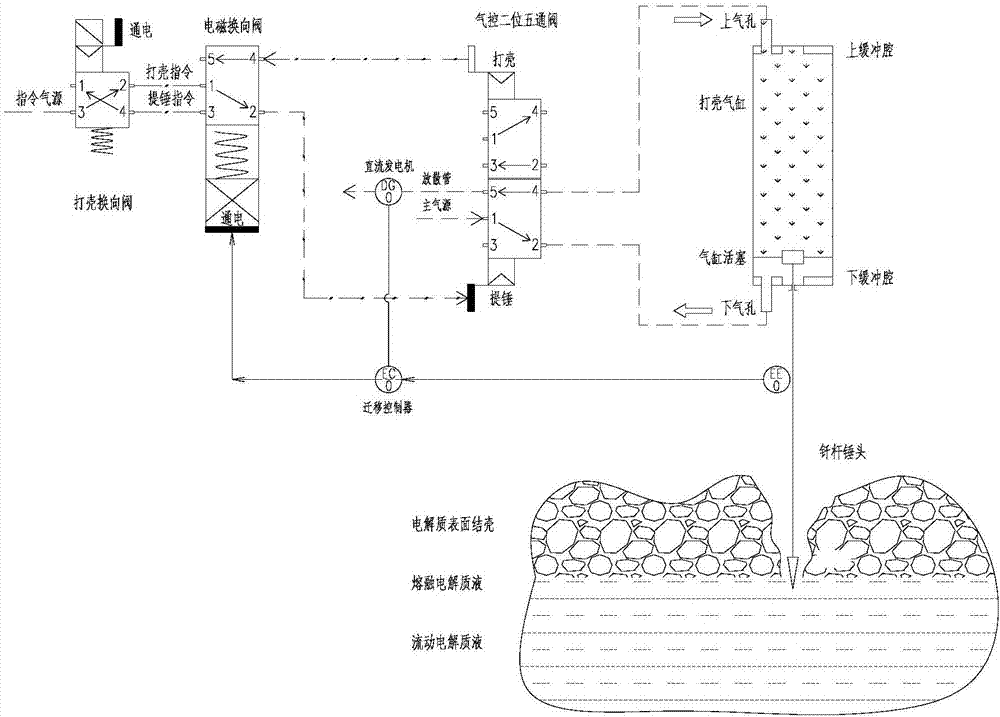

[0026] as attached figure 1 As shown in the diagram of the main components of the aluminum tank shelling air circuit and the electric control system, the shelling cylinder is installed vertically, and is demarcated up and down relative to the piston, with upper air holes and lower air holes respectively; the upper air hole and the No. Connection, the lower air hole is connected to the No. 2 air outlet, and the No. 1 air outlet of the air-controlled two-position five-way valve is connected to a 6-8Bar power supply source pipe.

[0027] When shelling, the shelling reversing valve in the air control cabinet on the ground is connected to the 2Bar air control command air sou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com