Sliding combination door

A technology of combining doors and door bodies, applied in the direction of windows/doors, door/window accessories, building components, etc., can solve the problems of complex structure of electric drive system, inconsistent speed of left and right roller shutters, easy corrosion and aging of structural parts, etc. The effect of derailment or stuck, saving power consumption and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing by non-limiting embodiment:

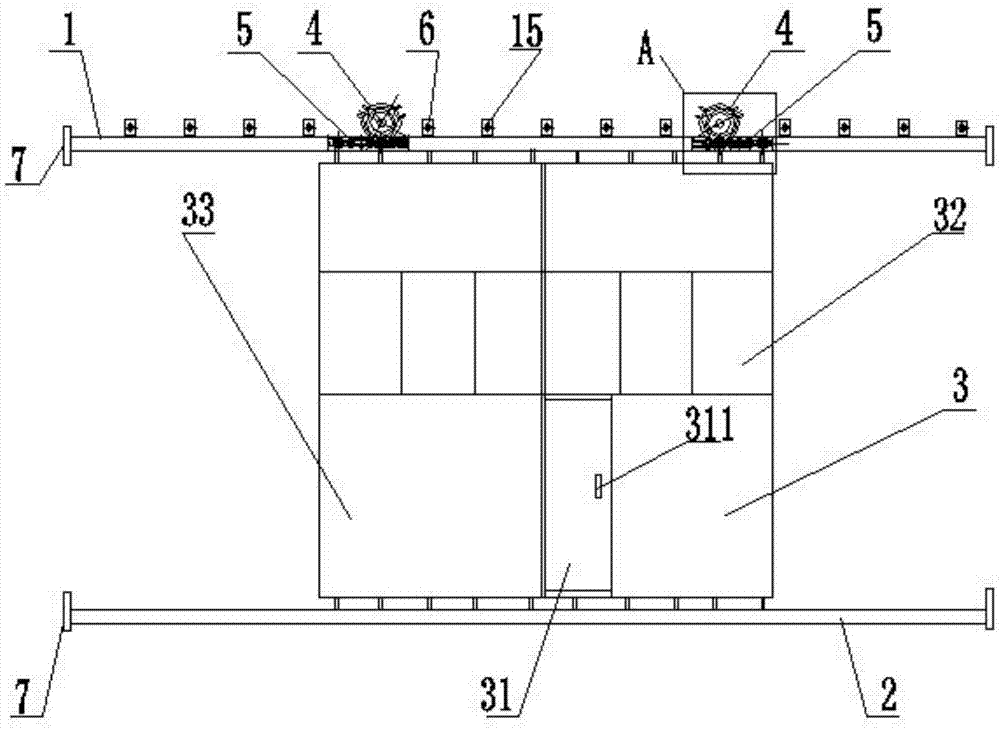

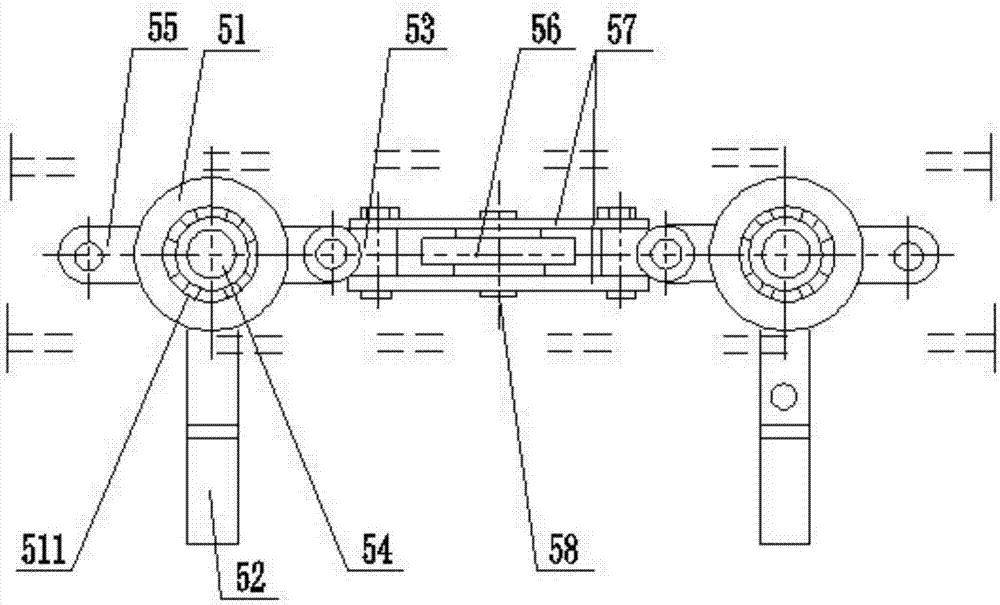

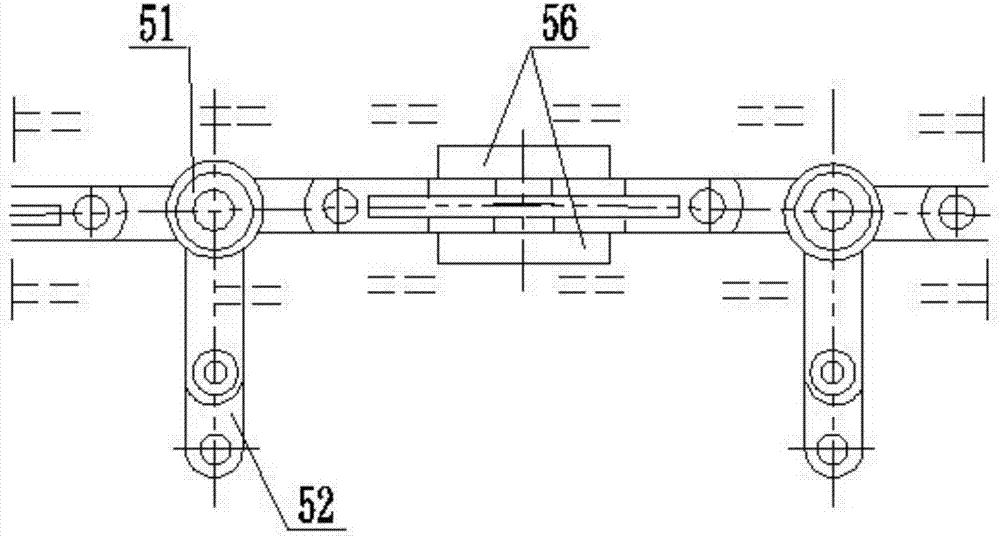

[0025] As shown in the drawings, a push-pull combination door includes two door bodies 3 arranged side by side, an upper guide rail 1, a lower guide rail 2, and two door body transmission mechanisms.

[0026] The door body 3 is a frame structure, the door surface of the door body 3 is inlaid with anti-static material or corrugated board, adopts the buckle bite mode, the door body 3 is provided with a small door 31, and the small door 31 is connected with the door body frame Adopt hinge connection, be provided with wicket 311 on wicket 31. A viewing window 32 is arranged at a suitable position of the door body. Around the inner side of the door body 3 is provided with a sealing rubber strip 34, which can be bonded to seal and prevent dust.

[0027] The upper guide rail 1 and the lower guide rail 2 are arranged in parallel on the upper and lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com